Production method for flat panel display

A flat-panel display and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, instruments, electric solid-state devices, etc., can solve problems such as difficulty in polysilicon thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

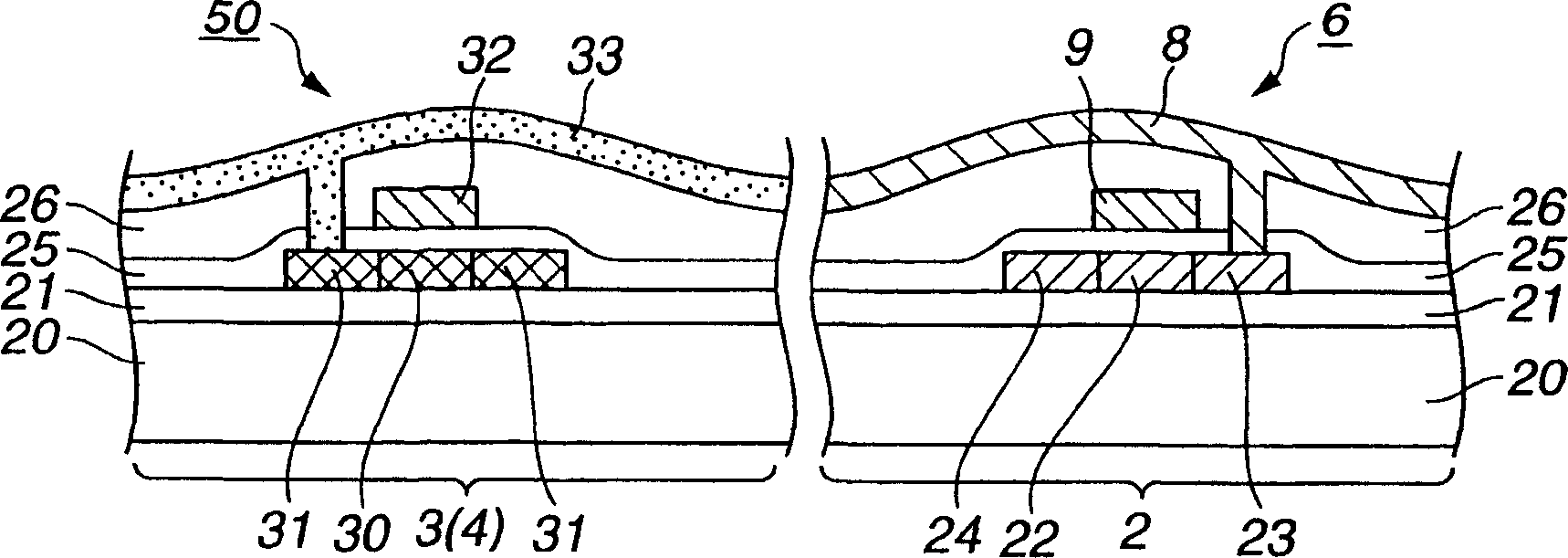

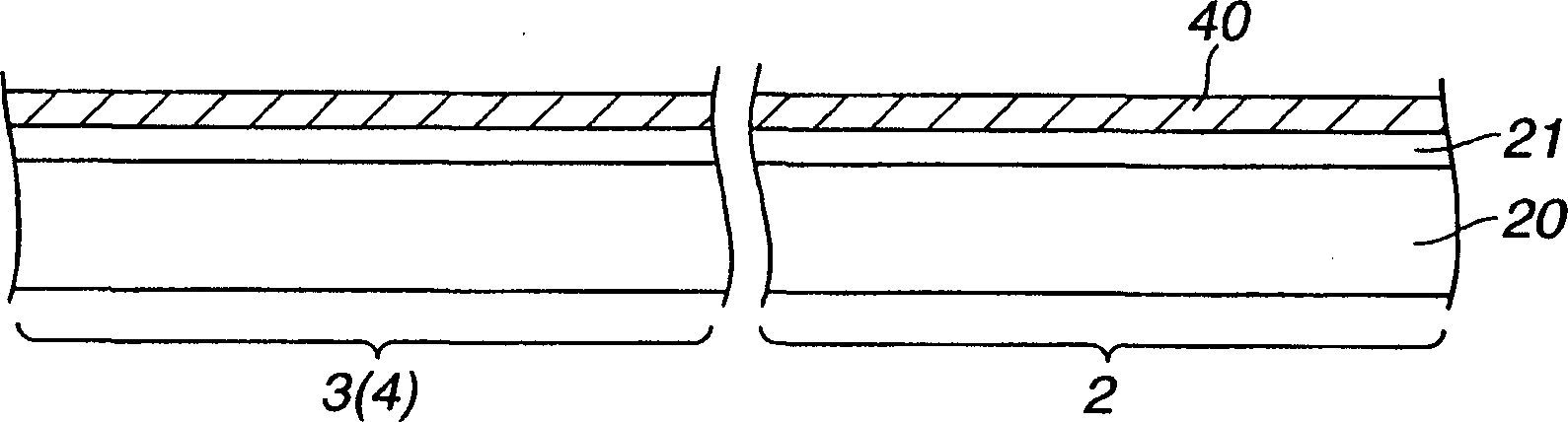

[0038] The invention will be described in detail below with the aid of the drawings. The present invention is suitably used in a liquid crystal display panel as a flat panel display.

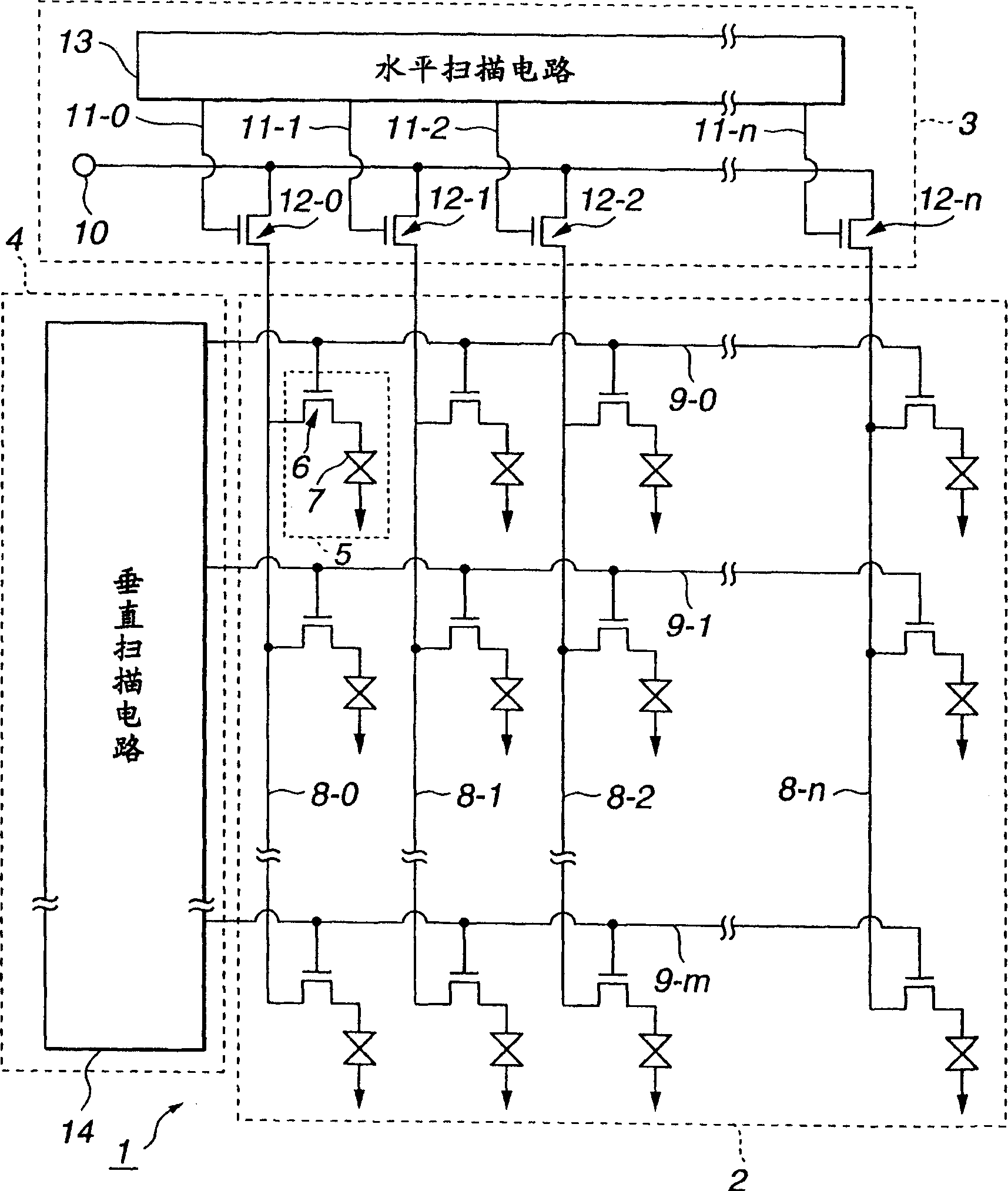

[0039] like figure 1 As shown, the liquid crystal display panel 1 to which the present invention is applied includes a pixel area 2, a horizontal scanning area 3 and a vertical scanning area 4, which are formed on the same glass substrate.

[0040] The horizontal scanning area 3 includes a horizontal scanning circuit 13 and (n+1) transistors 12 - 0 to 12 -n, and the (n+1) horizontal selection signal lines 11 - 0 to 11 -n are driven by the horizontal scanning circuit 13 . These horizontal selection signal lines 11-0 to 11-n are connected to the gates of the corresponding transistors 12-0 to 12-n.

[0041] The video signal terminal 10 is connected to one of the sources / drains of all the transistors 12-0~12-n, and the corresponding video signal lines 8-0~8-n are connected to the sources / drains of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com