Large fluidized bed reactor for wide sieving fluidized particles

A fluidized bed reactor, a large-scale technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as limiting the large-scale engineering amplification of the reactor process, and achieve the effect of improving the fluidization quality and realizing the amplification requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

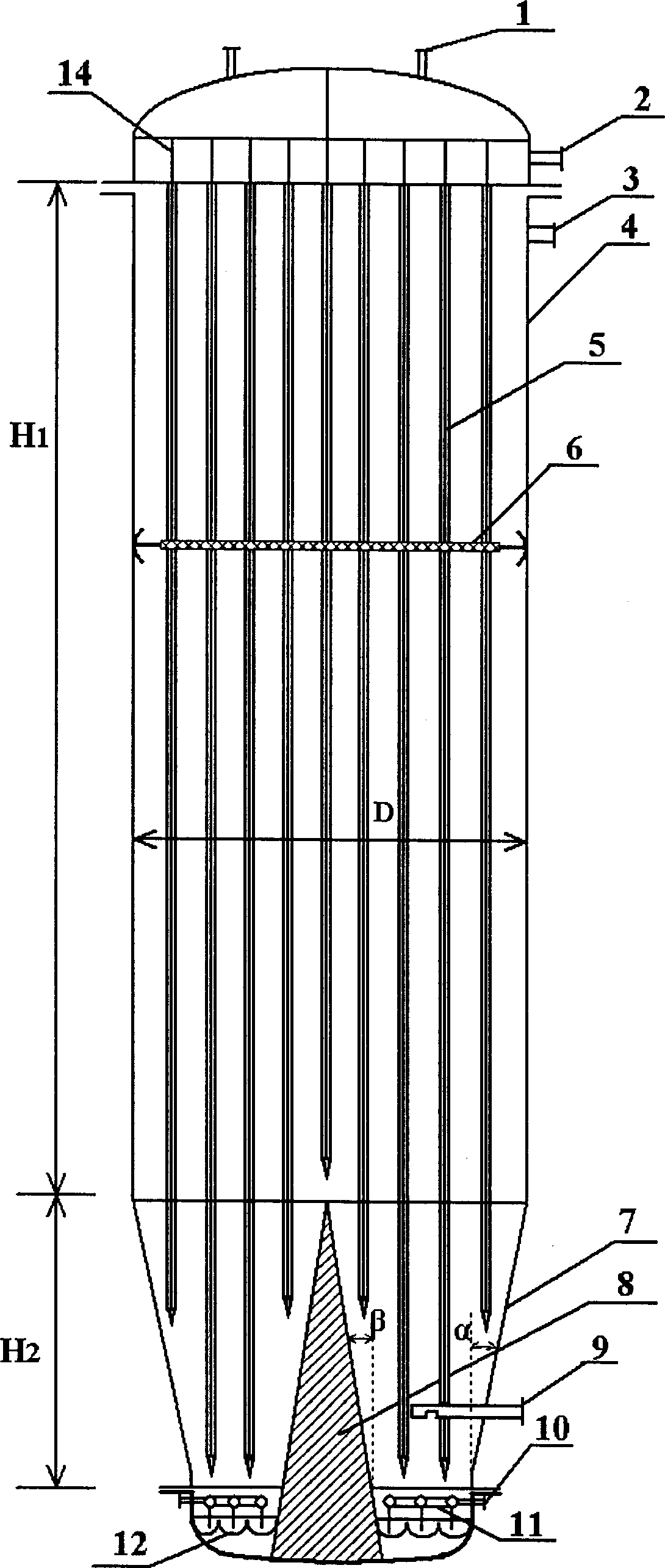

[0013] Describe concrete structure and mode of operation of the present invention in detail below in conjunction with accompanying drawing:

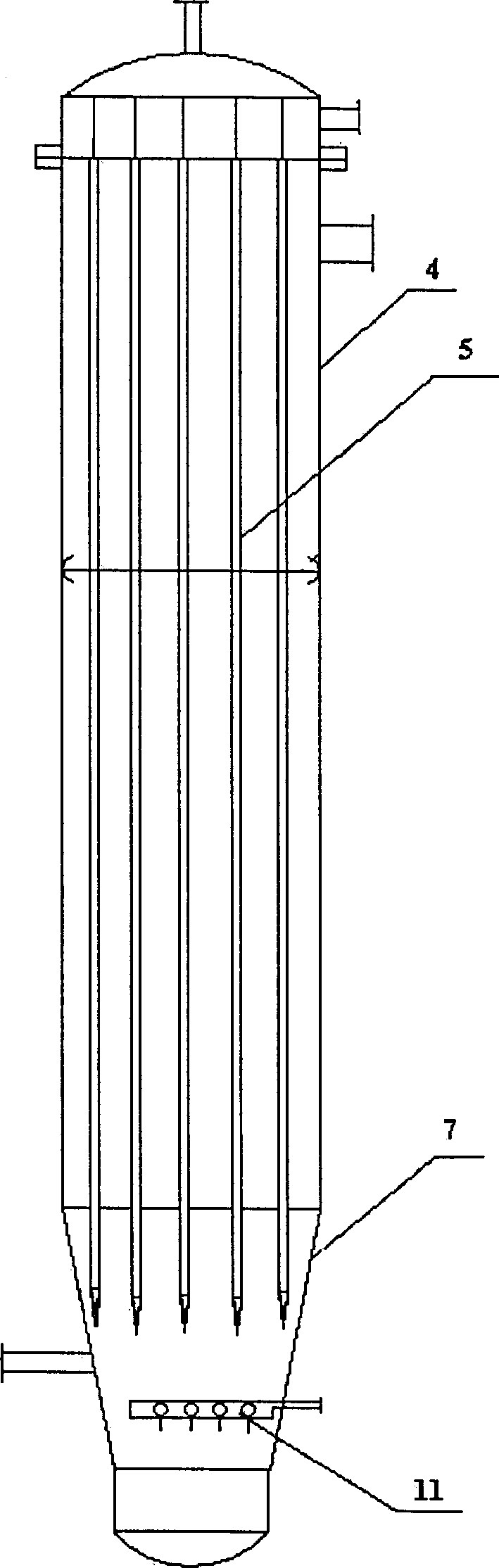

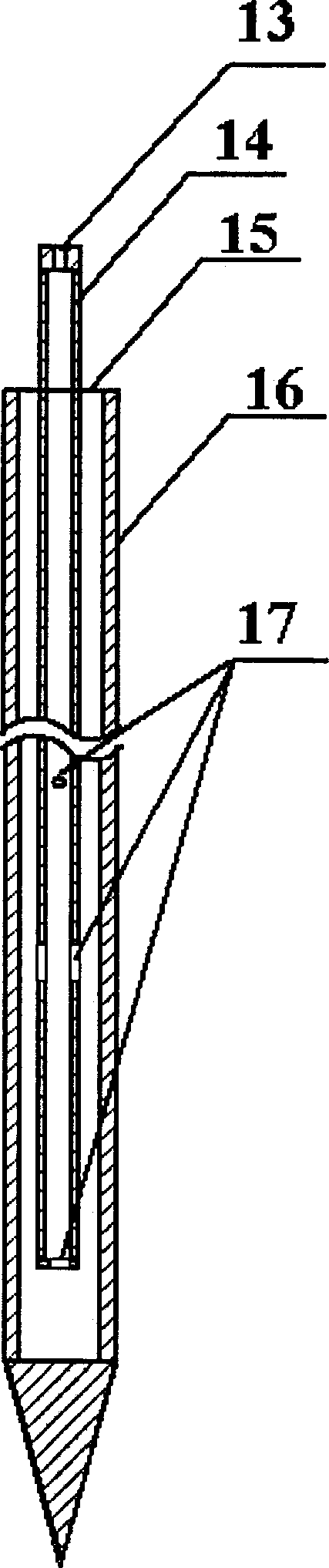

[0014] Large fluidized bed reactor of the present invention figure 2 It consists of a main bed 4, a conical bed 7, an annular gas distributor 10 and a finger tube heat exchange internal member 5. The diameter D of the main bed can be between 2.0 and 6.0m, and the height H 1 It can be between 8 and 15m; the height H of the conical bed 2 It can be between 1.8-4.5m, and the half-cone angle α can be between 7-13°; the inner cone structure 8 is introduced into the conical bed, and the half-cone angle β can be between 5-13°. All of the above can be selected according to specific circumstances. The cross-sectional area is double adjusted through the conical bed and the inner cone structure, and the gas velocity is effectively adjusted at the appropriate conical bed height, which avoids the problem that the simple use of the conical bed cann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com