Hood strengthening device of circulating fluidized bed

A technology of circulating fluidized bed and strengthening device, which is applied to fluidized bed combustion equipment, fuel burning in molten state, lighting and heating equipment, etc. problems, to increase flexibility, improve fluidization quality, and reduce equipment repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

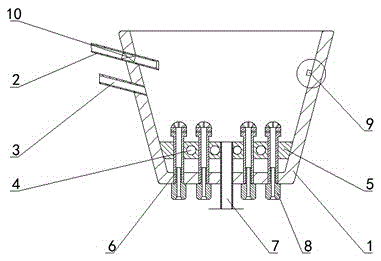

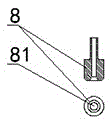

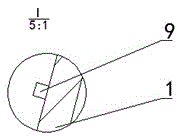

[0016] Such as figure 1 , figure 2 and image 3 As shown, a circulating fluidized bed air cap strengthening device includes an operating furnace 1, a secondary air inlet 2, a feed port 3, a cooling pipe 4, an air distribution plate 5, an air cap 6 and a slag discharge port 7. The operating furnace 1. The feed port 3 is provided on the left side, the secondary air inlet 2 is provided above the feed port 3, the air distribution plate 5 is provided at the bottom of the working furnace 1, and the air distribution plate 5 The cooling pipe 4 is provided inside, the slag discharge port 7 is provided in the middle of the air distribution plate 5 and passes through the bottom of the working furnace 1 , and the air cap 6 is provided on the air distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com