New-type expandable copolymer resin and preparation method thereof

An expandable copolymer resin, a new type of technology, applied in the field of lost foam casting material manufacturing, which can solve the problems of carbon defects, difficult decomposition, and slow EPS decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

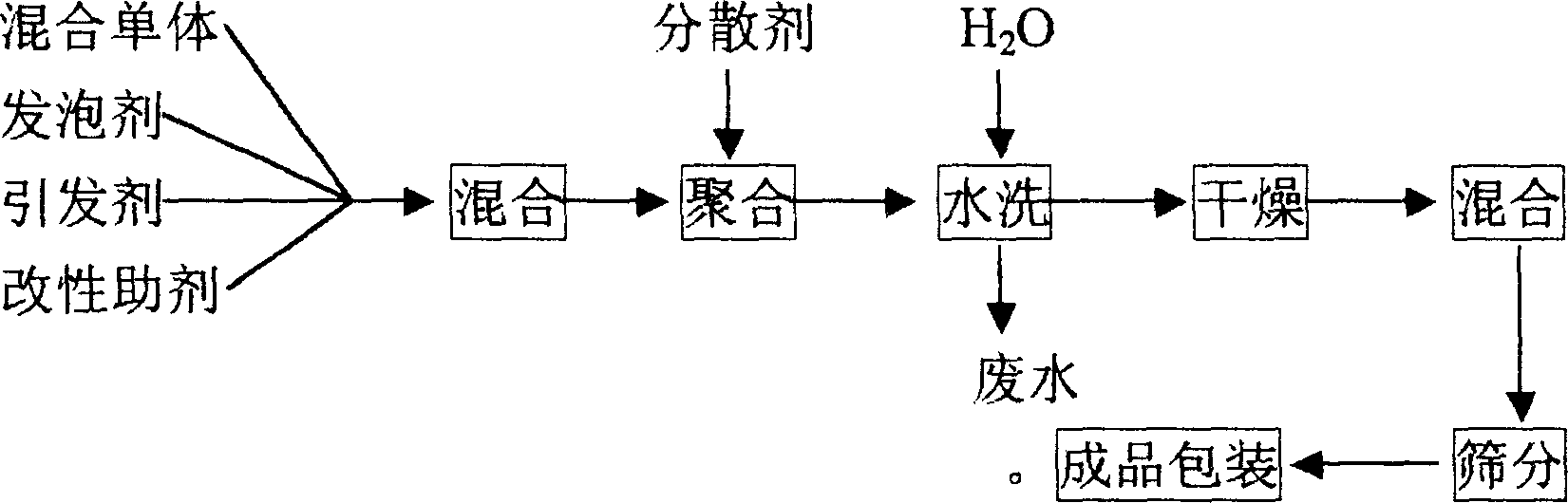

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: Novel expandable copolymer resin, (weight fraction) contains at least 100 mixed monomers, 300 deionized water, 0.3 dispersants, 8 foaming agents, 0.8 initiators, and 0.1 modification aids. The mixed monomer is composed of methyl methacrylate (MMA) and styrene (ST), and its MMA:ST=5:95; the initiator is organic peroxide: BPO, TBPO, TBPB; the blowing agent is C 4 -C 6 Low-boiling hydrocarbon compounds; modified additives mainly include divinylbenzene (DVB), ethylene glycol dimethacrylate (DMAE), cetyl methacrylate, etc.; dispersant is cellulose ether, mainly hydroxy Ethyl cellulose ether, hydroxypropyl cellulose ether, etc.

Embodiment 2

[0012] Example 2: On the basis of Example 1, (weight fraction) mixed monomer 100, deionized water 150, dispersant 0.6, foaming agent 15, initiator 0.3, modification aid 0.02. Its MMA:ST=95:5.

Embodiment 3

[0013] Example 3: On the basis of Example 1, (weight fraction) mixed monomer 100, deionized water 225, dispersant 0.45, foaming agent 11.5, initiator 0.55, modification aid 0.06. Its MMA:ST=50:50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com