Load uniforming detection device and method for serial combined thrust bearing

A technology of thrust bearing and detection device, which is applied in the direction of mechanical bearing testing, rigid support of bearing components, bearing components, etc., and can solve problems such as vibration noise and fatigue life test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

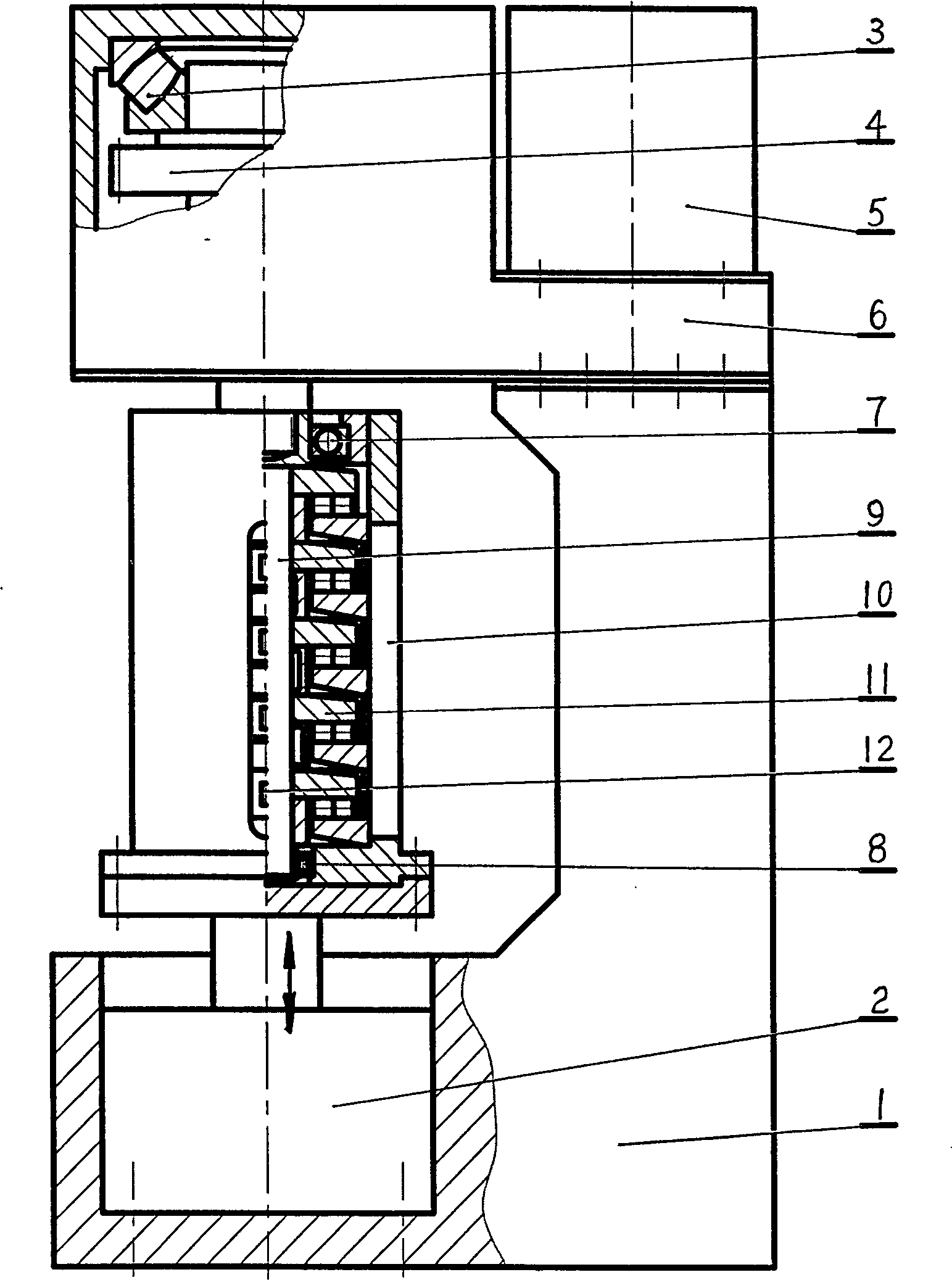

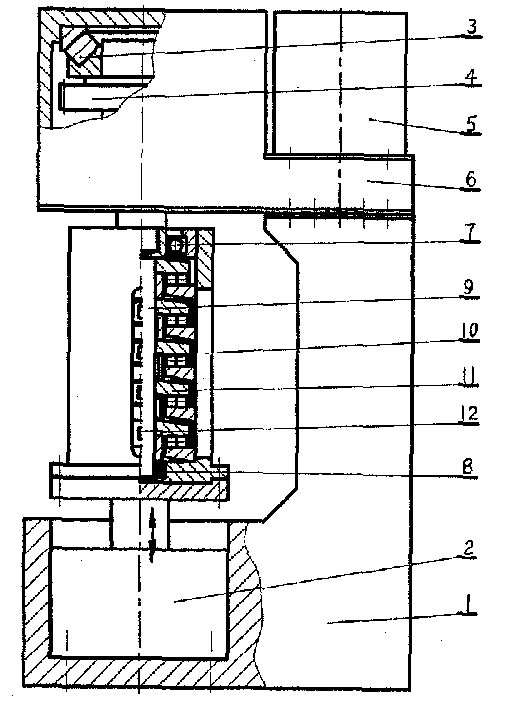

[0008] Such as figure 1 As shown, the detection device of the present invention mainly includes: a vertical frame 1, an oil cylinder 2, a thrust bearing 3, a transmission gear mechanism 4, a motor 5, a power box 6, radial bearings 7 and 8, a mandrel 9, and a fixed bearing Seat 10, series combined thrust cylindrical roller bearing 11, resistance strain gauge 12; oil cylinder 2 is arranged and installed under the vertical frame 1, power box 6 is installed above the vertical frame 1, and the drive in the power box 6 The output shaft is equipped with a large thrust bearing 3, and the bearing fixing seat 10 is fixed on the output end of the piston rod of the oil cylinder 2 by screws; the series combined thrust cylindrical roller bearing 11 is located in the bearing fixing seat 10, and the radial bearings 7 and 8 are located in the At both ends of the bearing holder 10, the mandrel 9 is located in the center hole of the radial bearings 7, 8 and the tandem combined thrust cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com