An adjustable cable trench construction cover

A cable trench and adjustable technology, which is applied in the direction of cable laying equipment, electrical components, switchgear, etc., can solve the problems of increased construction costs of cable trench cover plates, and achieve optimal horizontal laying effects, high construction efficiency, and high load-carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

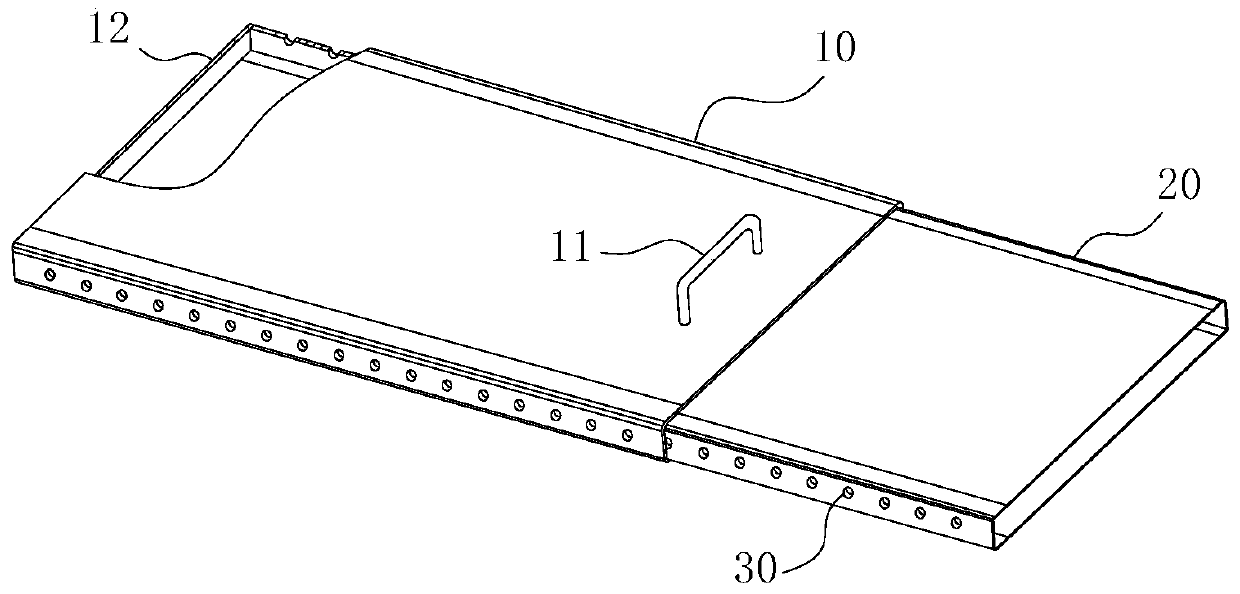

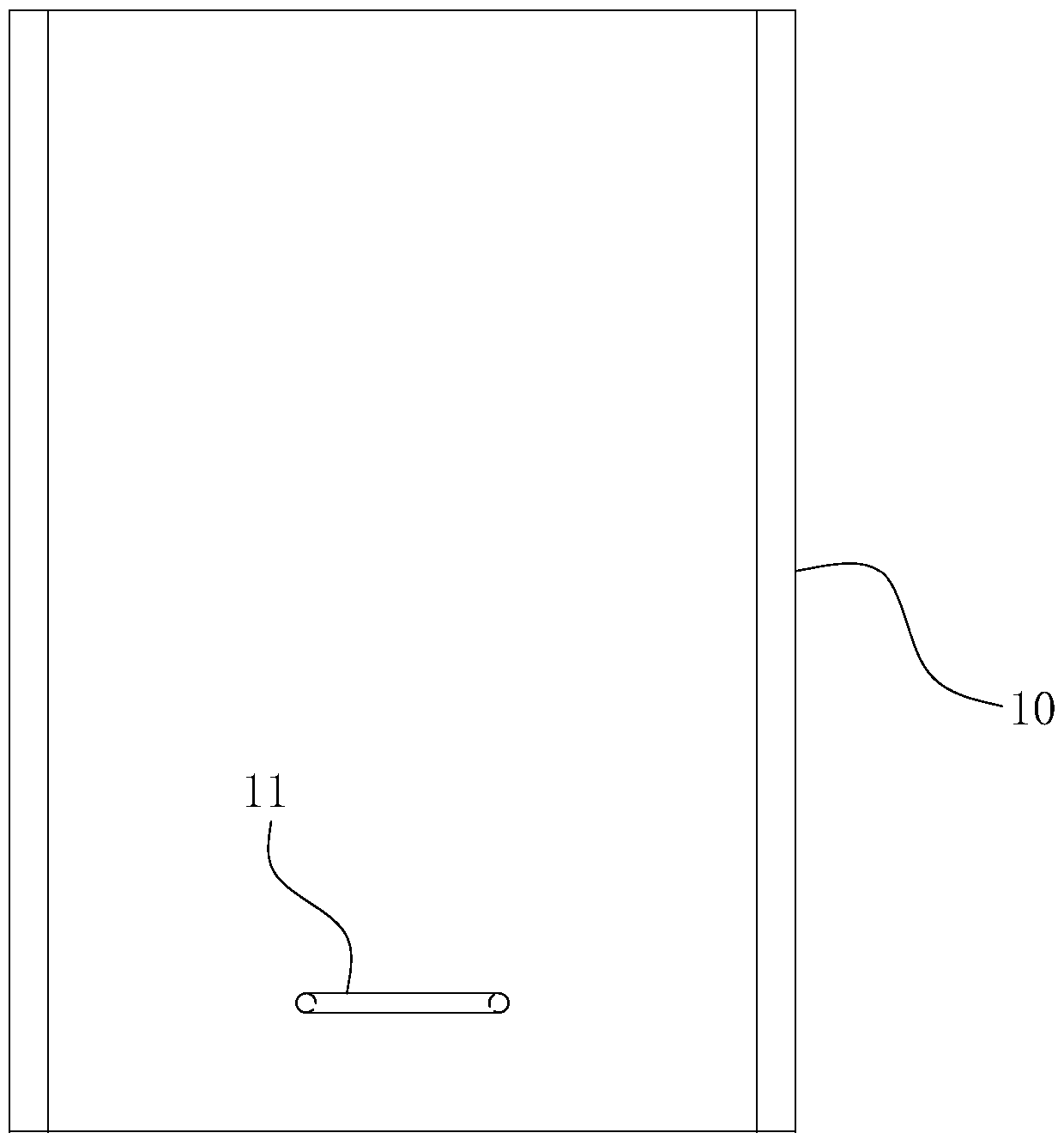

[0027] For ease of understanding, combined here Figure 1-5 Concrete structure and workflow of the present invention are further elaborated as follows:

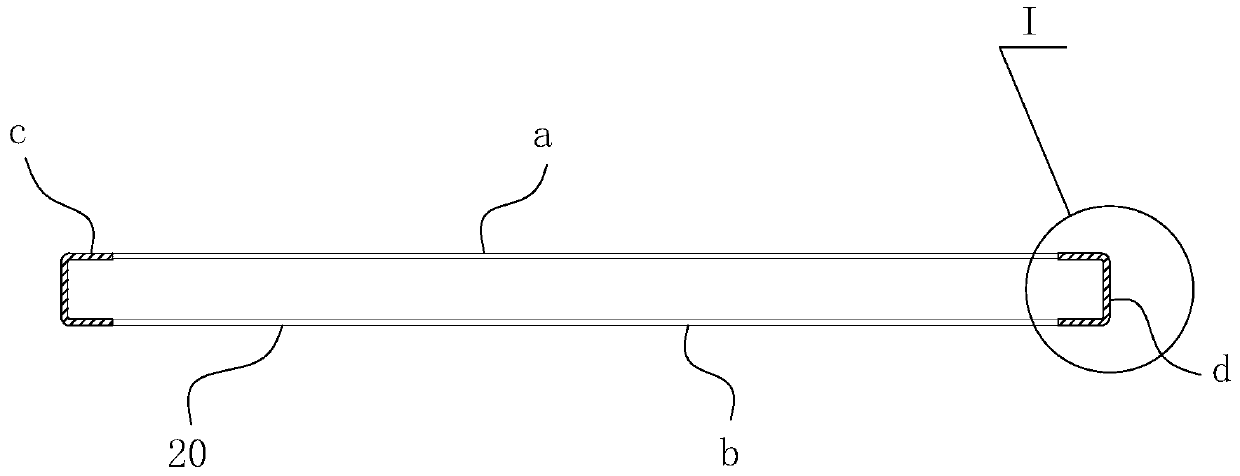

[0028] The specific implementation structure of the present invention is as figure 1 As shown, it is a double-layer structure formed by nesting the inner cover plate 20 and the outer cover plate 10 . When not in use, the inner cover 20 can be completely placed in the outer cover 10 for easy transportation. When in use, the inner plate can be pulled out to a specified length according to the width of the cable trench to meet the coverage of cable trenches of different widths. Both the inner cover plate 20 and the outer cover plate 10 are welded by subunits, including the upper plate body a and the lower plate body b forming the upper and lower plate surfaces thereof, and the left side plate c and the right side plate forming the left and right side walls thereof d. The left and right side plates c and d are in the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com