Reflecting device for illuminating

A reflection device and reflector technology, applied in lighting devices, fixed lighting devices, lighting applications, etc., can solve problems such as high outgoing light, failure to form, scratches, etc., and achieve less reflected scattered light, good productivity, and high flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

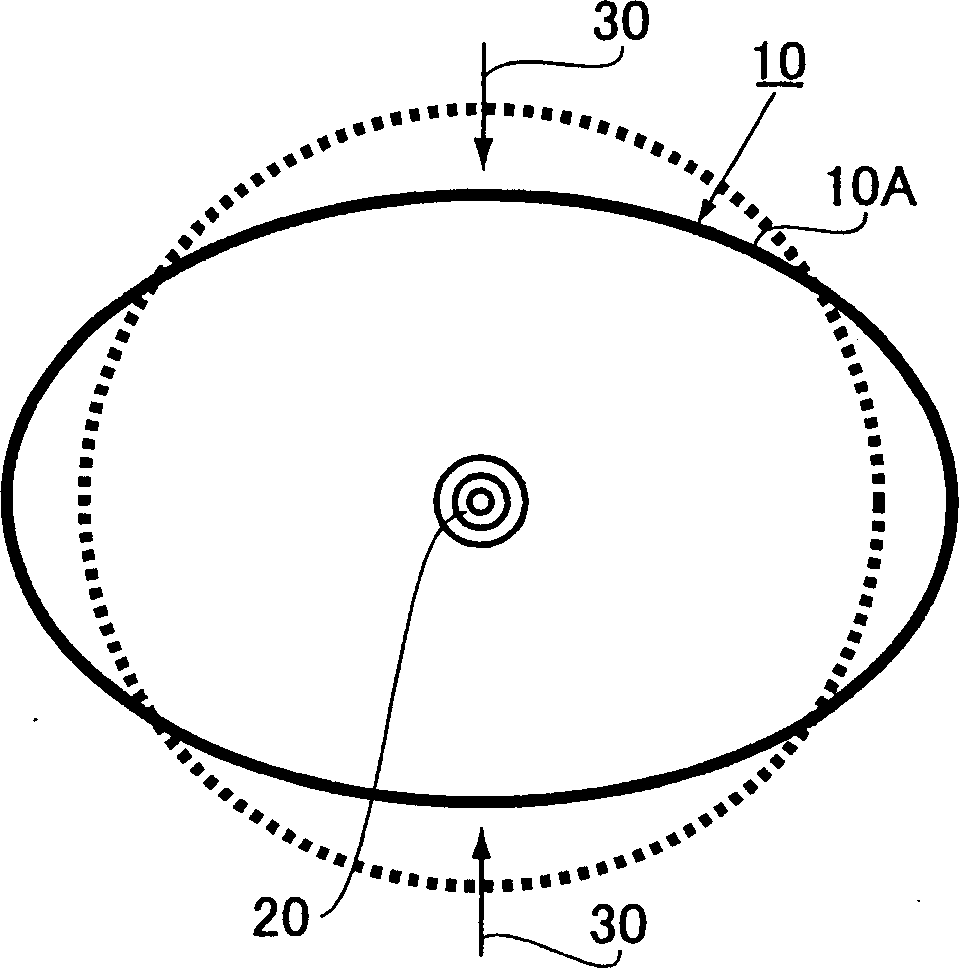

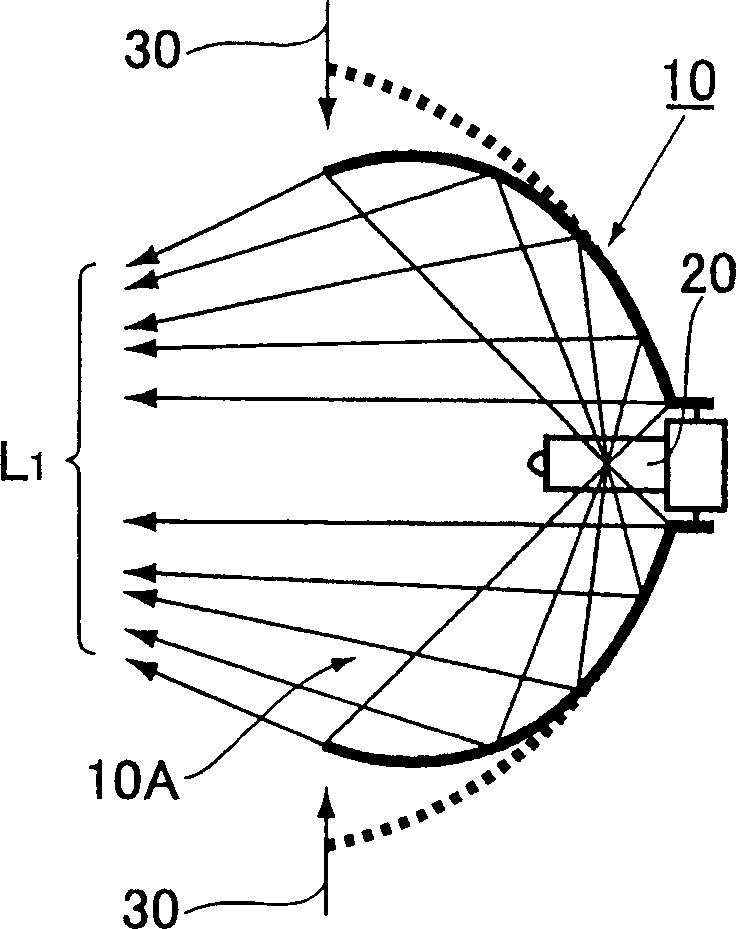

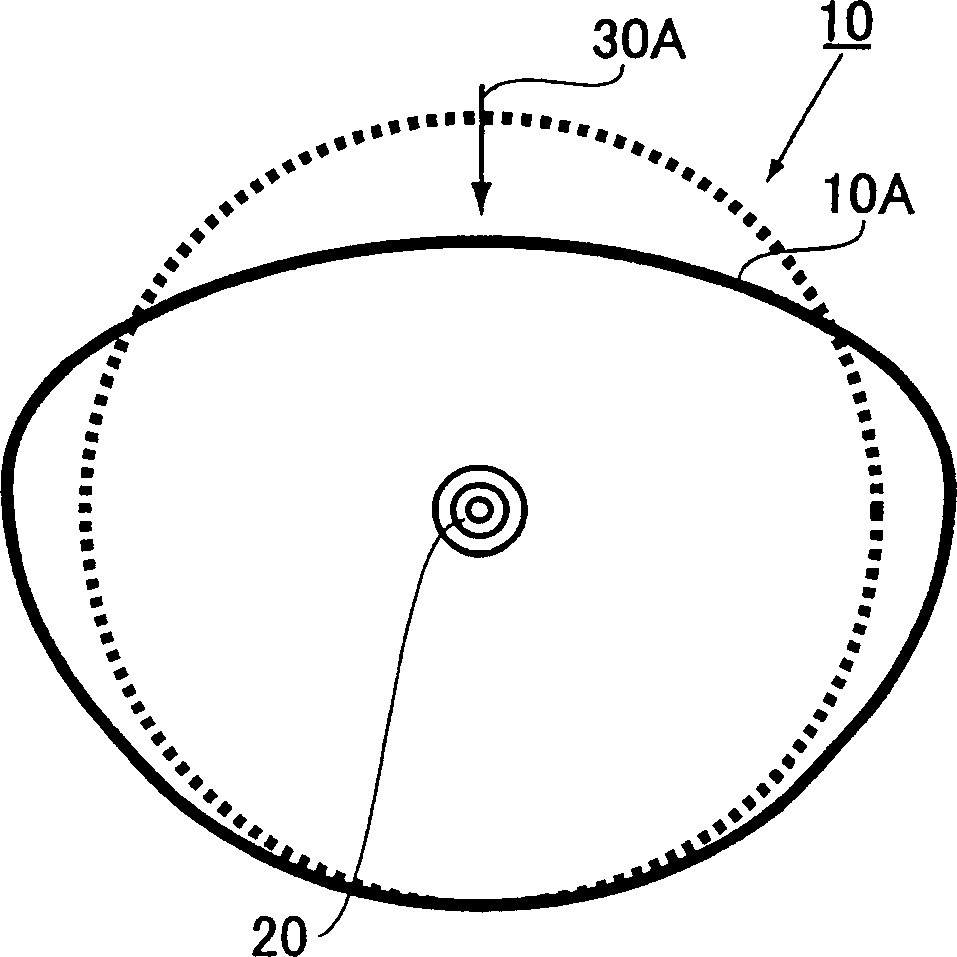

[0035] Preferred embodiments of the present invention will be described below with reference to the drawings. FIG. 1 and FIG. 2 are schematic diagrams of a preferred reflective device for lighting in the present invention. The reflector 10 on the illuminating reflector reflects the light emitted by the light source 20 onto the reflective surface and emits the light in a specific direction from the output opening 10A. image 3The configuration of reflector 10 is shown. Part A in the figure is an enlarged view of the cross section. The reflector 10 is a film-shaped single body, and is formed of a substrate 10a having a concave curved surface and a reflective film 10b formed on the concave curved surface. The reflective film 10b is formed by vapor-depositing metal such as aluminum, and the reflective surface 10B can be formed on the inner surface of the reflector 10 by the reflective film 10b.

[0036] The base material 10a is a bent and formed film-shaped member produced by a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com