Two-in-one permanent magnet brushless electomotor with internal rotor

A permanent magnet motor, two-in-one technology, applied in the direction of motor starting, mechanical equipment, engine components, etc., can solve the problems of the number of coil winding turns affected by space, large starting current, electromagnetic interference, etc., to optimize the external mechanical Features, increased starting torque, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

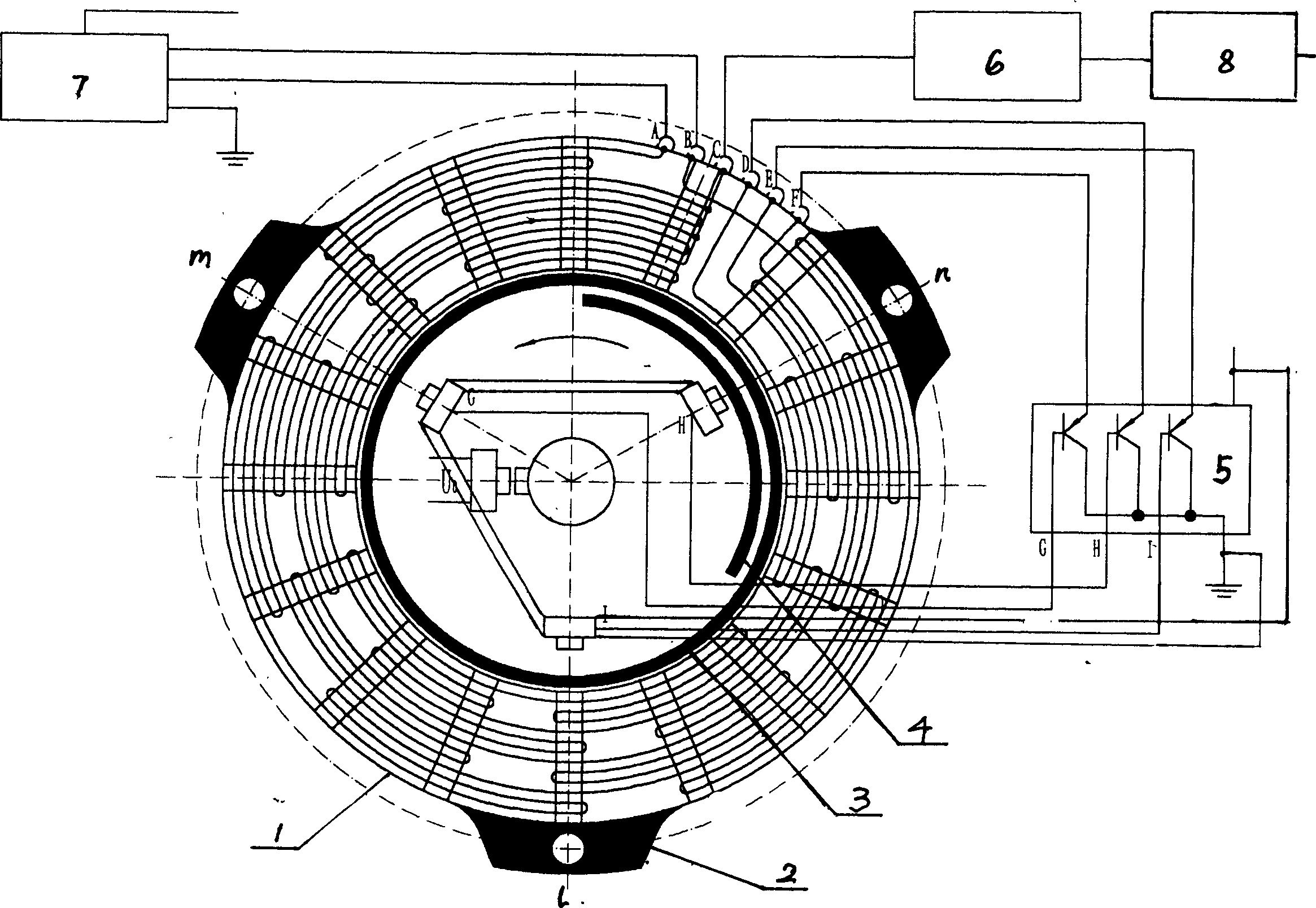

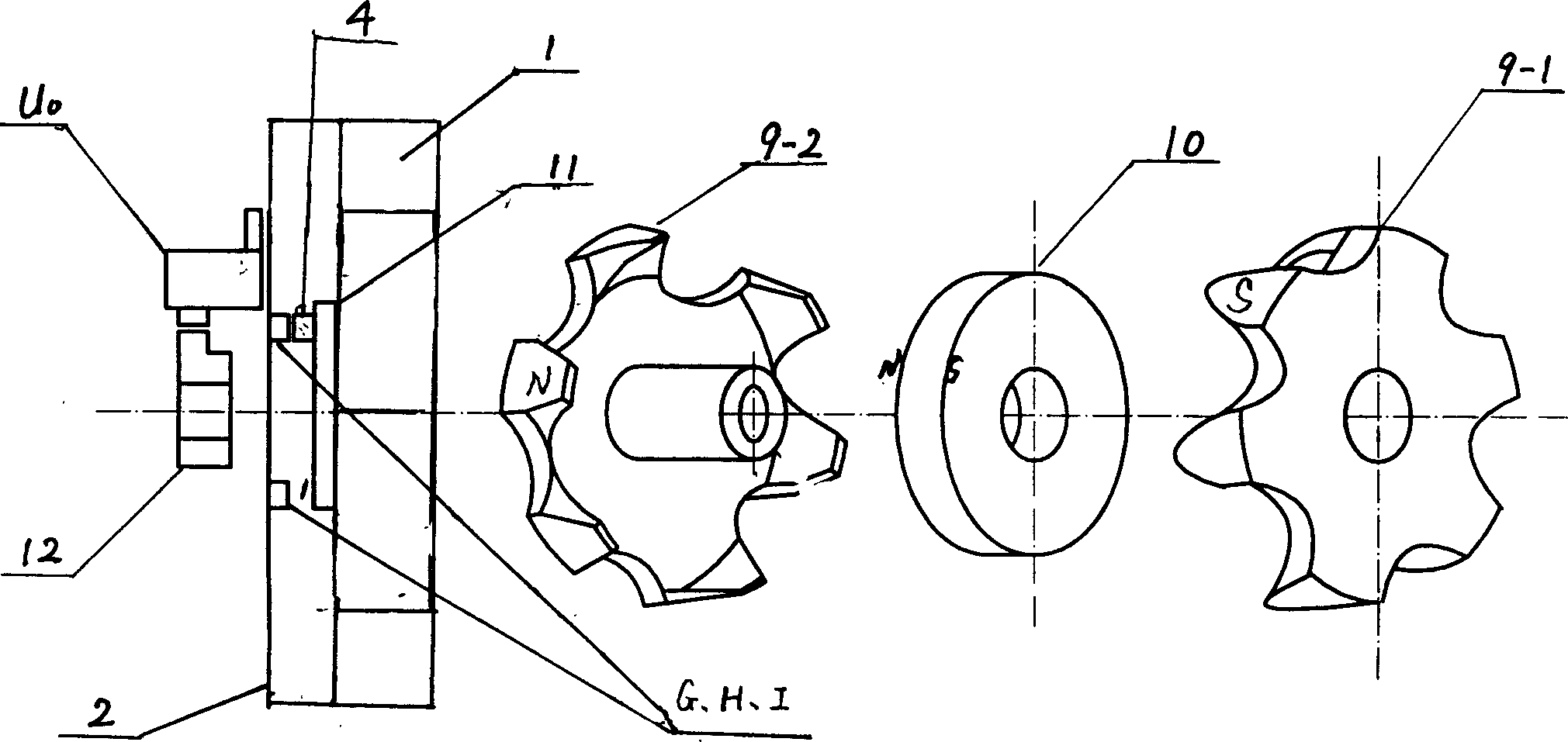

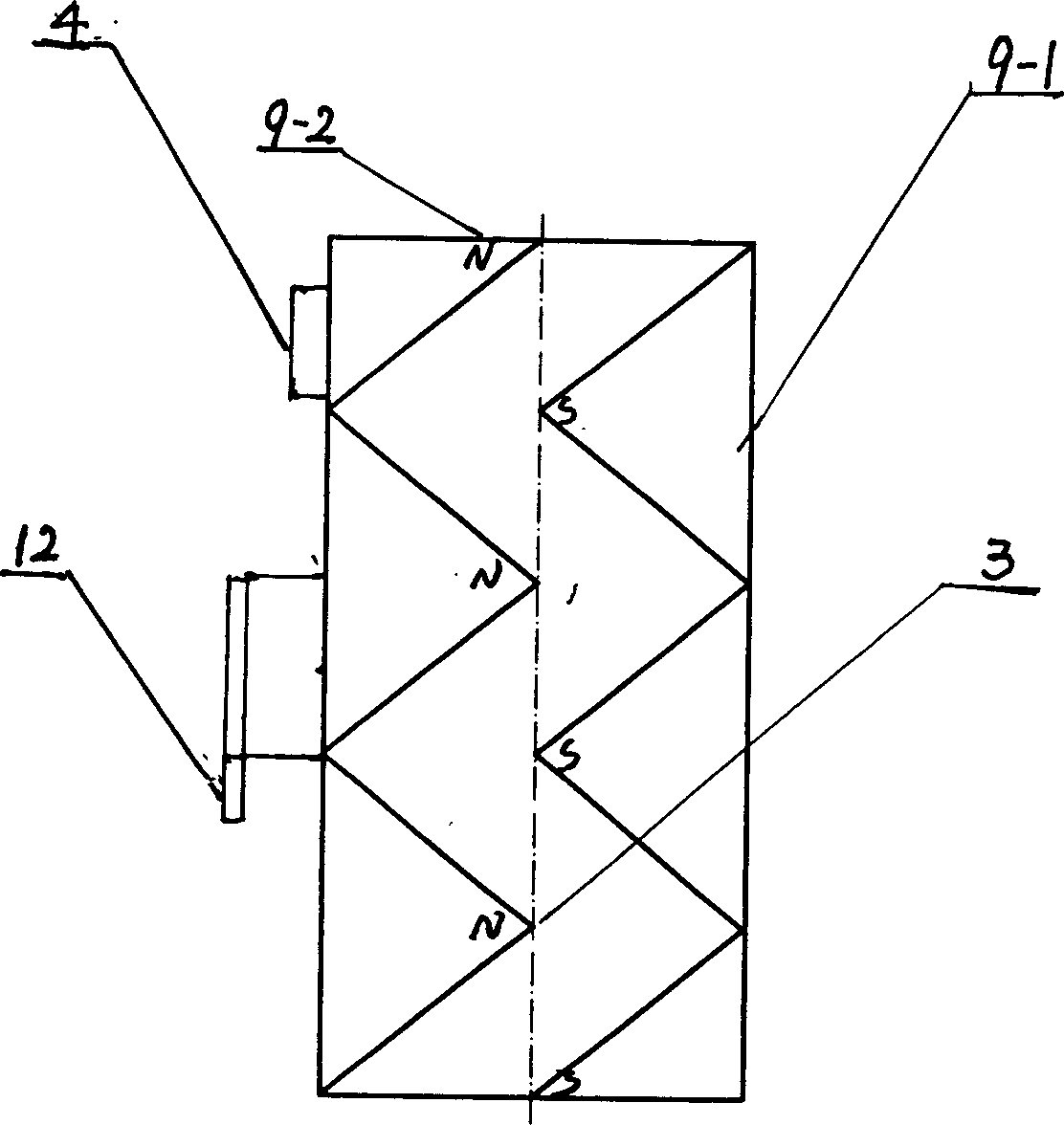

[0018] For the structure of this motor see figure 1 and figure 2 , including a stator core 1, a rotor 3, a skeleton shell 2 connecting the core to the engine, a hall sensor magnet 4, a controller 5, an overcurrent protection circuit 6, a rectifier 7, a starting relay 8, a pair of beak-shaped magnets for the rotor 9 -1 and 9-2, magnetic steel 10, non-conductive disk 11, ignition timing bump 12, generator coils A, B, starter coils CD, CE, CF and Hall sensors G, H, I. The rotor 3 is installed on the crankshaft of the engine, and the stator core 1 is installed outside the rotor 3. The stator core 1 has starting coils CD, CE, CF and generator coils A and B on the stator core 1. The frame shell 2 of the stator core 1 is connected to the engine, and the outer end surface of the frame shell 2 is installed with an ignition pulse sensor U 0 , corresponding to the ignition timing bump 12, the ignition timing bump 12 is installed coaxially with the rotor 3. Three Hall sensors G, H, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com