Mask-pattern correction method

A correction method and mask pattern technology, applied in the field of photolithography, can solve problems such as easy formation of depressions, and achieve the effects of improving uniformity, reducing writing and viewing time, and reducing file size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Figure 3A to Figure 3D As shown, it is a schematic flowchart of a method for correcting a mask pattern according to a preferred embodiment of the present invention.

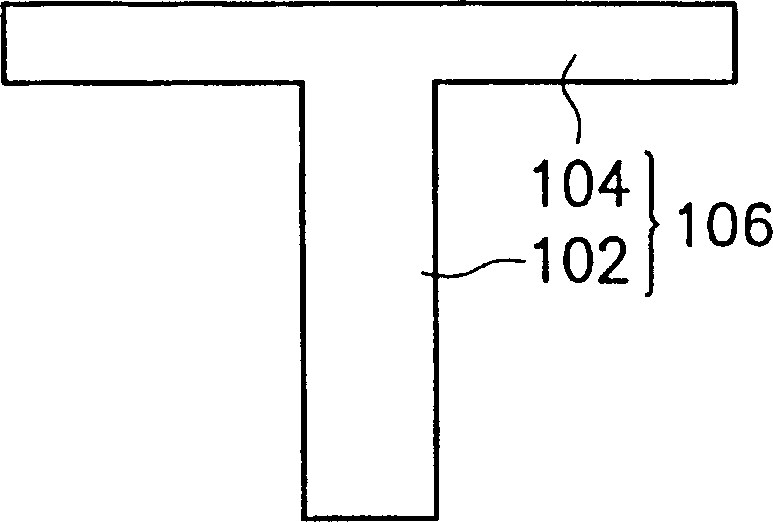

[0035] Please refer to Figure 3A First, a T-shaped original pattern 306 composed of a first long strip pattern 302 and a second long strip pattern 304 is provided. The first elongated original pattern 302 is connected to the middle section of the second elongated pattern 304.

[0036] After that, please refer to Figure 3B , Perform a first correction step, add an auxiliary pattern 308 on both sides of the first strip pattern 302 to form a first correction pattern 310, wherein the first correction pattern 310 includes a T-shaped original pattern 306 and an auxiliary pattern 308. The shape of the auxiliary pattern 308 is, for example, a stripe shape.

[0037] Next, please refer to Figure 3C , A second correction step is performed to reduce a portion of the first strip-shaped pattern 302 to form a second cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com