2-propyl enanthaldehyde preparation method

A kind of technology of propyl heptanal and propyl group, applied in the field of preparing compound 2-propyl heptanal, can solve the problems such as the preparation method of 2-propyl heptanal has not been found yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

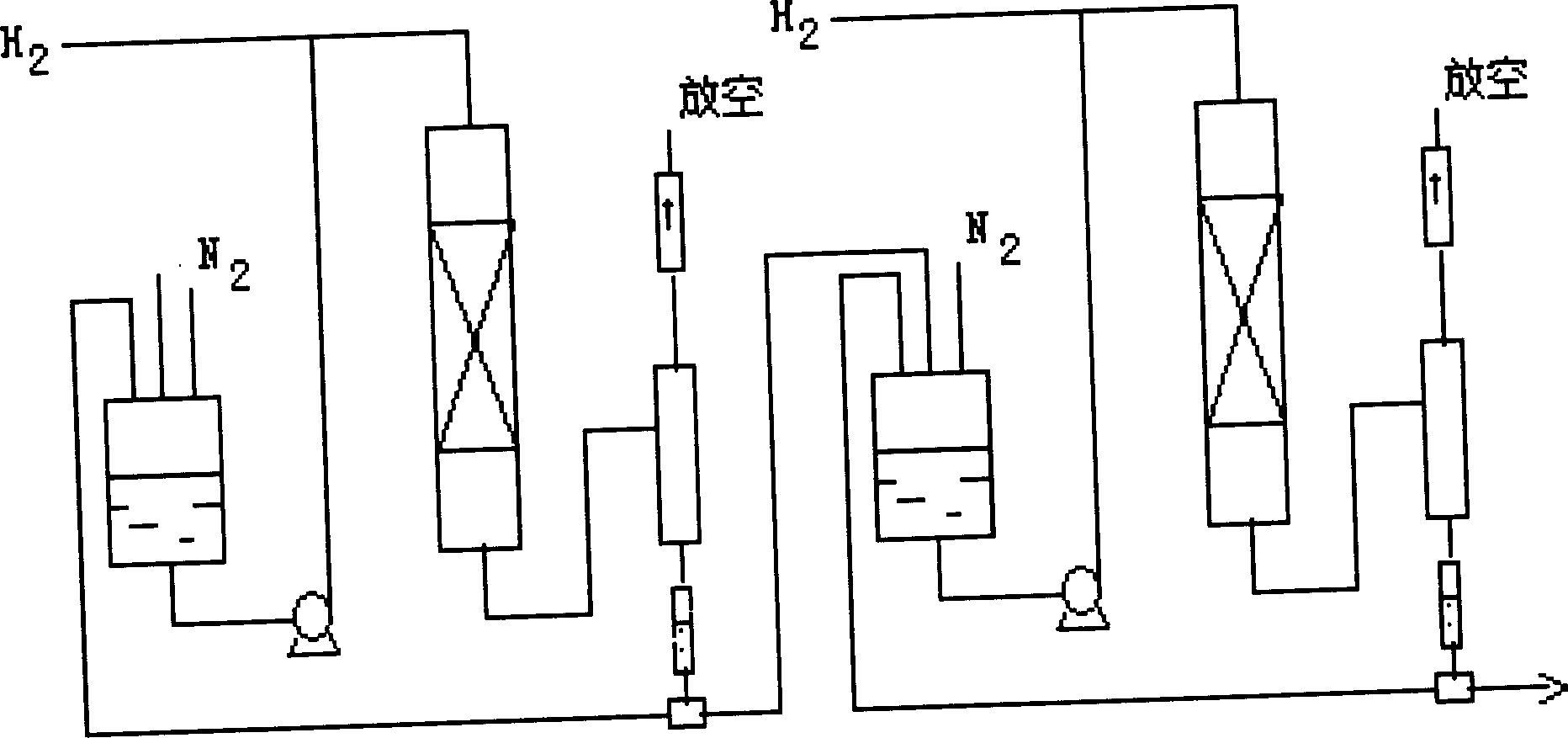

[0014] The selective hydrogenation of 2-propyl-2-heptenal was carried out in a two-stage serial fixed-bed flow system with reflux as shown in the accompanying drawing. Before the reaction starts, the catalyst needs to be pre-reduced. At 200°C and under the reaction pressure, the catalyst is reduced with hydrogen flow for 12 hours, and then lowered to the reaction temperature. The selective hydrogenation reaction is carried out at a certain temperature and pressure, and the alkenal raw material is pumped from the upper end of the reactor at a certain flow rate, and the tail gas flow rate is controlled to determine the molar ratio of the hydrogen to the alkenal. After the system was stabilized, samples were collected and analyzed regularly.

[0015] Table 1 is the reaction conditions tested, LOOP1 is the first-stage reactor loop, and LOOP2 is the second-stage reactor loop. Wherein the space velocity is measured by the liquid hourly volumetric space velocity of fresh raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com