Magnetic yoke for electromagnetic clutch

A technology of electromagnetic clutches and yokes, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problem of high installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

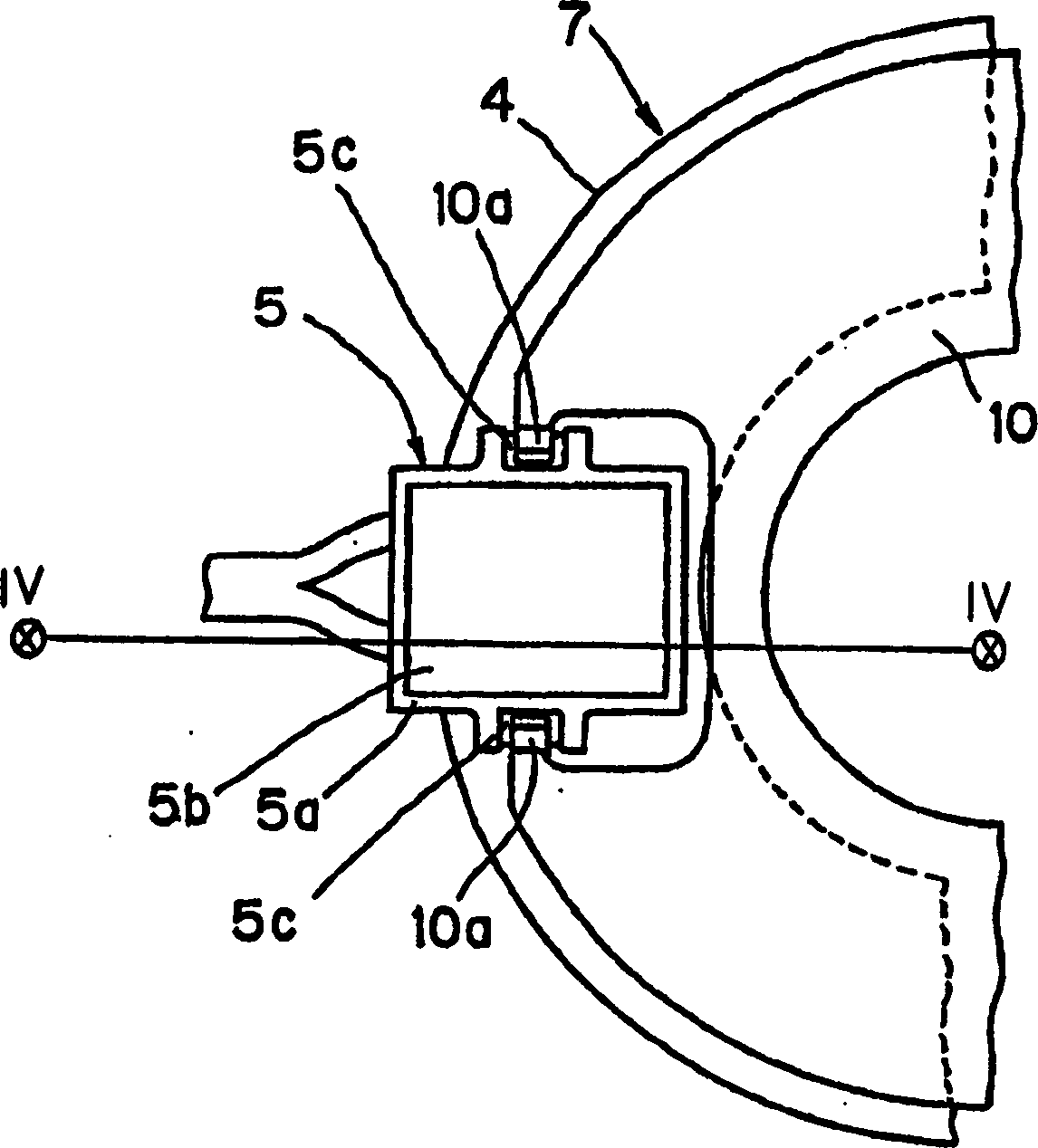

[0029] FIG. 5(a) is an exploded perspective view of the connection structure of the external wires 6a, 6b and the terminal portions 2a, 2b (not shown) of the coil 2 of the present invention. The main element of the invention is a pair of contact elements 11 . The contact element 11 is in the shape of a rectangular parallelepiped including an upper plate 11a, a pair of first side plates 11f, 11f opposed to each other, and a pair of second side plates 11c, 11c opposed to each other. The interior of the contact element 11 is hollow, and there is no bottom plate opposite the upper plate 11a.

[0030] A slit 11g cut from the bottom side of the contact member 11 is provided on each of the pair of first side plates 11f, 11f. On each of the pair of second side plates 11c, 11c, slits 11d, 11e cut out from the bottom side of the contact member 11 are provided.

[0031] Diode 12 has leads 12a and 12b.

[0032] Two circular grooves 5g, 5g for accommodating external wires 6a, 6b are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com