Cold-pressurized adhesive paper tape

A self-adhesive, tape paper technology, applied in the direction of adhesives, film/flake adhesives, etc., can solve the problems of difficult peeling, excessive adhesive strength, and tearing of substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

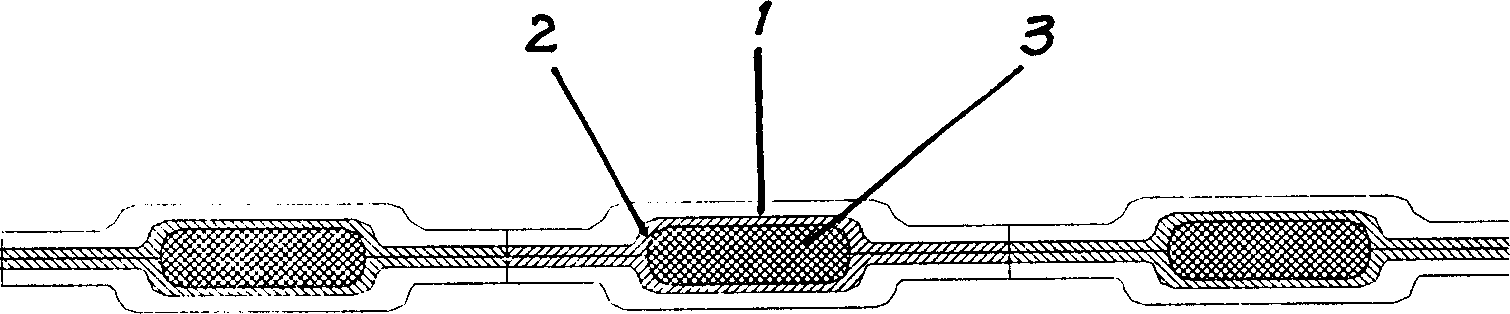

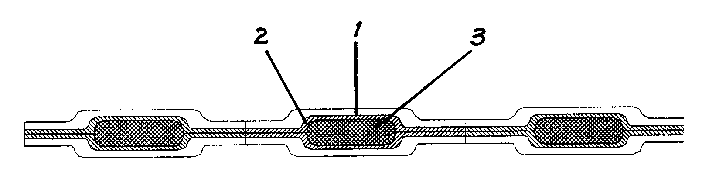

Image

Examples

Embodiment 1

[0019] Add 0.1 part (weight) of commercially available rubber anti-aging agent in 20 parts (weight) of acetic acid and (meth)acrylic acid ester monomer copolymer with a solid content of 45%, and add a natural rubber latex with a solid content of 60% after stirring 100 parts (weight), add soft water or distilled water 40 parts (weight) again, be made into viscose liquid. Coat the formulated adhesive solution at 60g / m 2 On the surface of the paper substrate, the thickness of the coating layer is 8~29g / m 2 (solid content) is better, and then all or most of the water in the coating is evaporated by heat drying, and then cut into cold-pressed self-adhesive tapes according to the length and width required by the user. Example 2

Embodiment 2

[0020] Add 0.2 part (weight) of commercially available rubber anti-aging agent in 100 parts (weight) of natural latex with a solid content of 60%, add acetic acid and (meth)acrylic ester monomer copolymers with a solid content of 45% after stirring 40 parts (weight), add soft water or distilled water 50 parts (weight) again, be made into viscose liquid. Coat the formulated adhesive solution at 70g / m 2 On the surface of the paper substrate, the thickness of the coating layer is 8~29g / m 2 (solid content) is better, and then all or most of the water in the coating is evaporated by heat drying, and then cut into cold-pressed self-adhesive tapes according to the length and width required by the user.

Embodiment 3

[0022] Add 1 part (weight) of commercially available rubber anti-aging agent in 50 parts (weight) of acetic acid and (meth)acrylic acid ester monomer copolymer with a solid content of 45%, and add the natural rubber latex with a solid content of 60% after stirring 100 parts (weight), add soft water or distilled water 60 parts (weight) again, be made into viscose liquid. Coat the formulated adhesive solution at 80g / m 2 On the surface of the paper substrate, the thickness of the coating layer is 8~29g / m 2 (solid content) is better, and then all or most of the water in the coating is evaporated by heat drying, and then cut into cold-pressed self-adhesive tapes according to the length and width required by the user.

[0023] The self-adhesive strength of cold-pressed self-adhesive tape paper of the present invention is carried out as follows:

[0024] A1 Sample collection and processing

[0025] It should be carried out in accordance with the provisions of GB / T450 and GB / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com