Surface mounted antenna, its making process and radio communicator with the antenna

A surface-mounted antenna technology, applied to antennas, slot antennas, antenna components, etc., can solve problems such as poor operating efficiency, radiating electrode resonance frequency error, and high manufacturing cost of surface-mounted antennas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

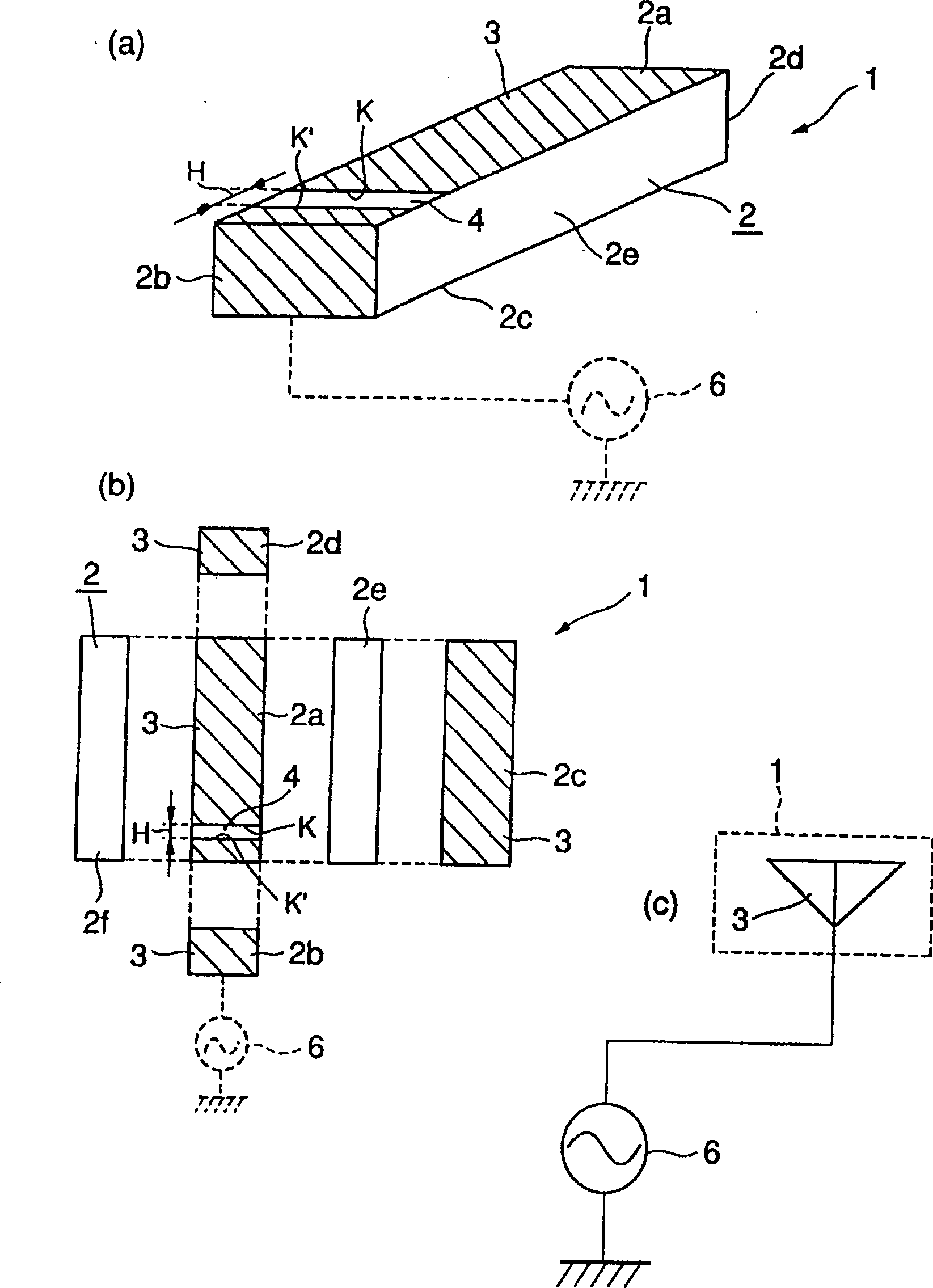

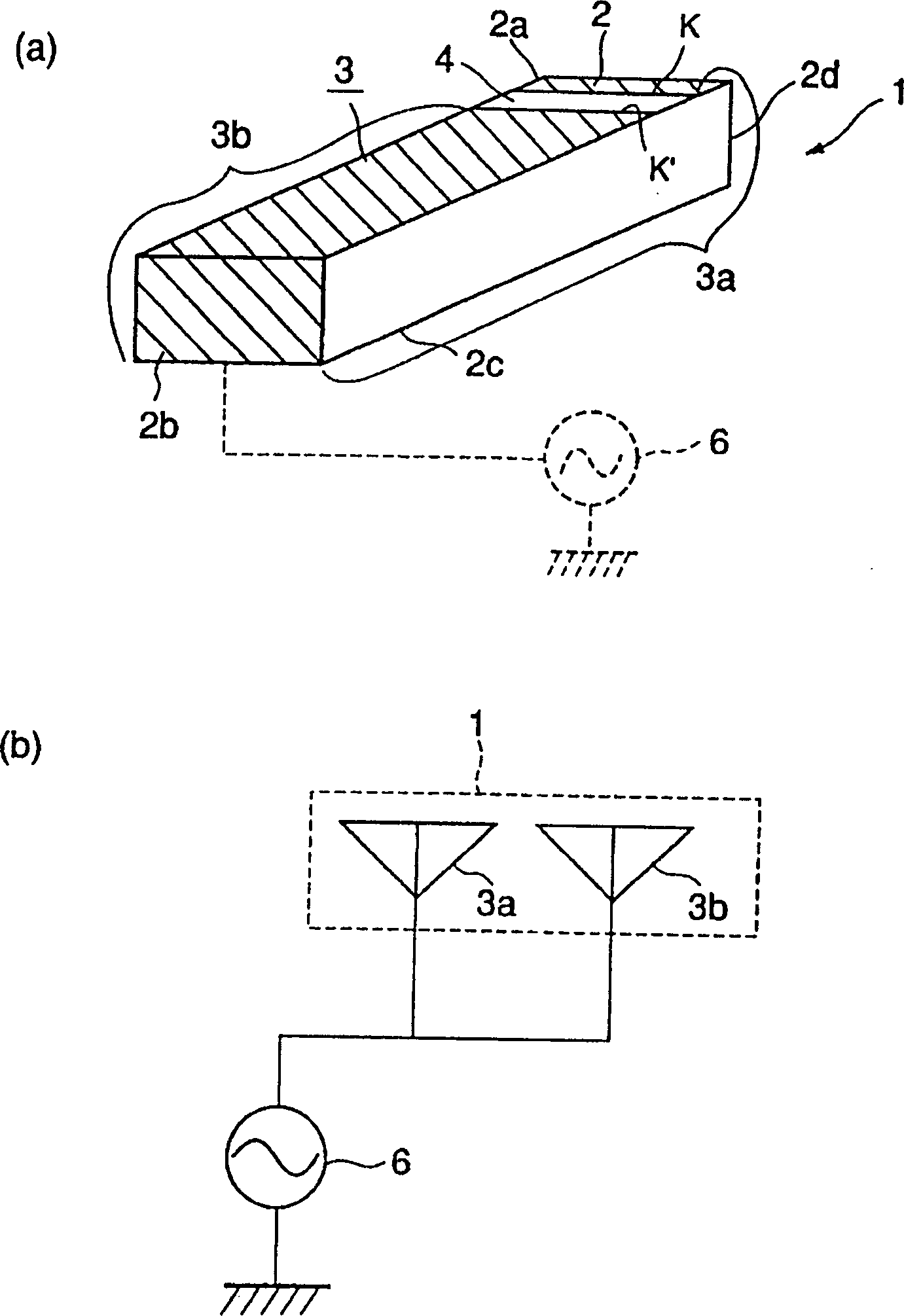

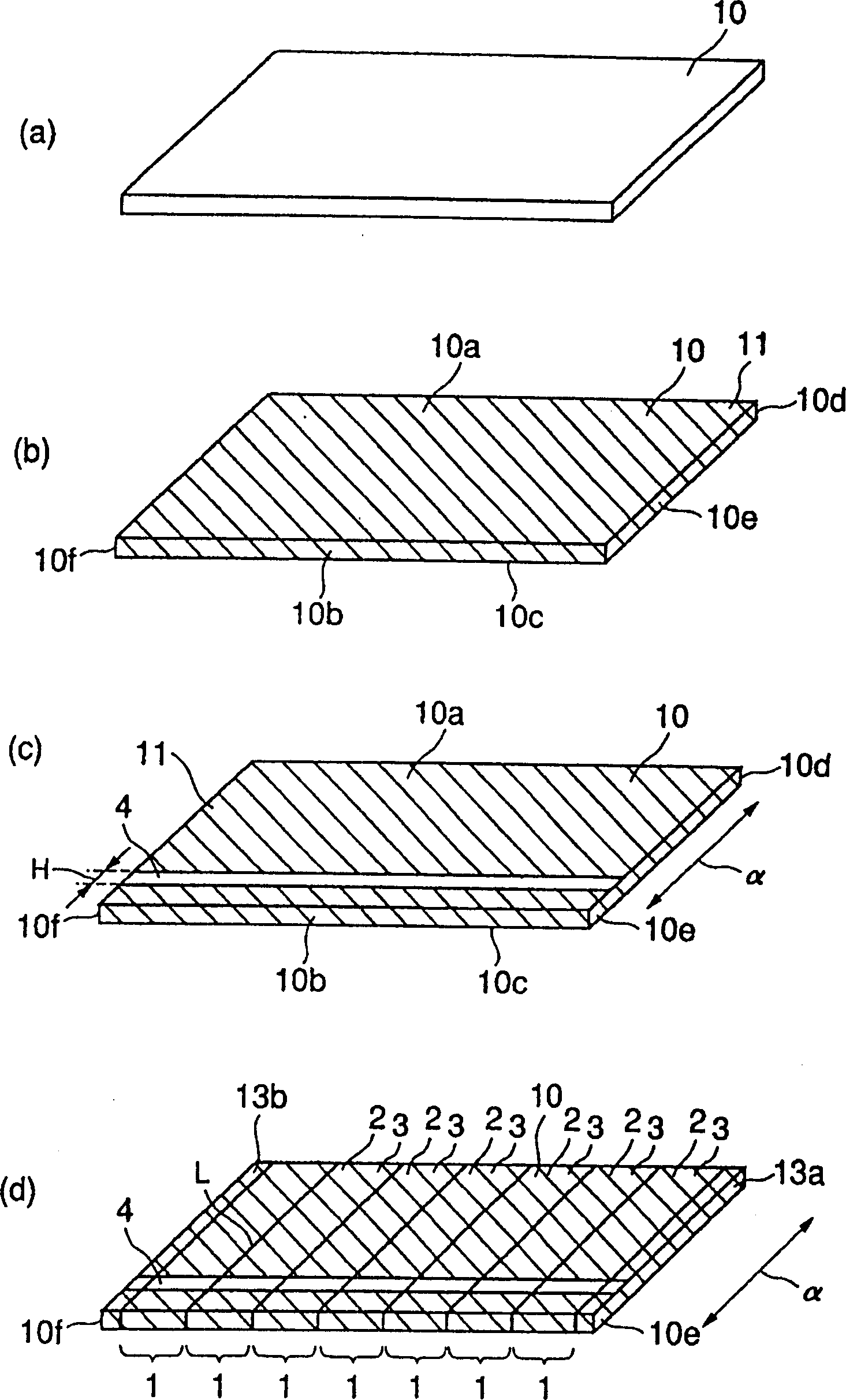

[0020] An example of an embodiment of the present invention will be described below with reference to the drawings.

[0021] exist figure 1 In (a), a characteristic surface mount type antenna in the radio communication device of the example of the first embodiment is schematically shown in perspective view, figure 1 (b) shown as figure 1 (a) Expanded view of the surface-mounted antenna shown. In addition, there are various structures of the radio communication device. According to the example of the first embodiment, any structure other than the surface-mounted antenna of the radio communication device can be adopted, and the structure other than the surface-mounted antenna is omitted here. Description of the structure of the radio communication machine.

[0022] In this example of the first embodiment, the characteristic surface mount antenna 1 has a cuboid (thin rectangular) substrate 2 made of a dielectric, and four continuous surfaces of the substrate 2, that is, a fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com