Solid-liquid separation process of concentrated fermented rice liquid

A technology of concentrated mash fermentation and solid-liquid separation, applied in the fields of environmental protection and alcohol, can solve problems such as the pollution of distiller's grains, and achieve the effects of reducing production water, reducing equipment investment and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

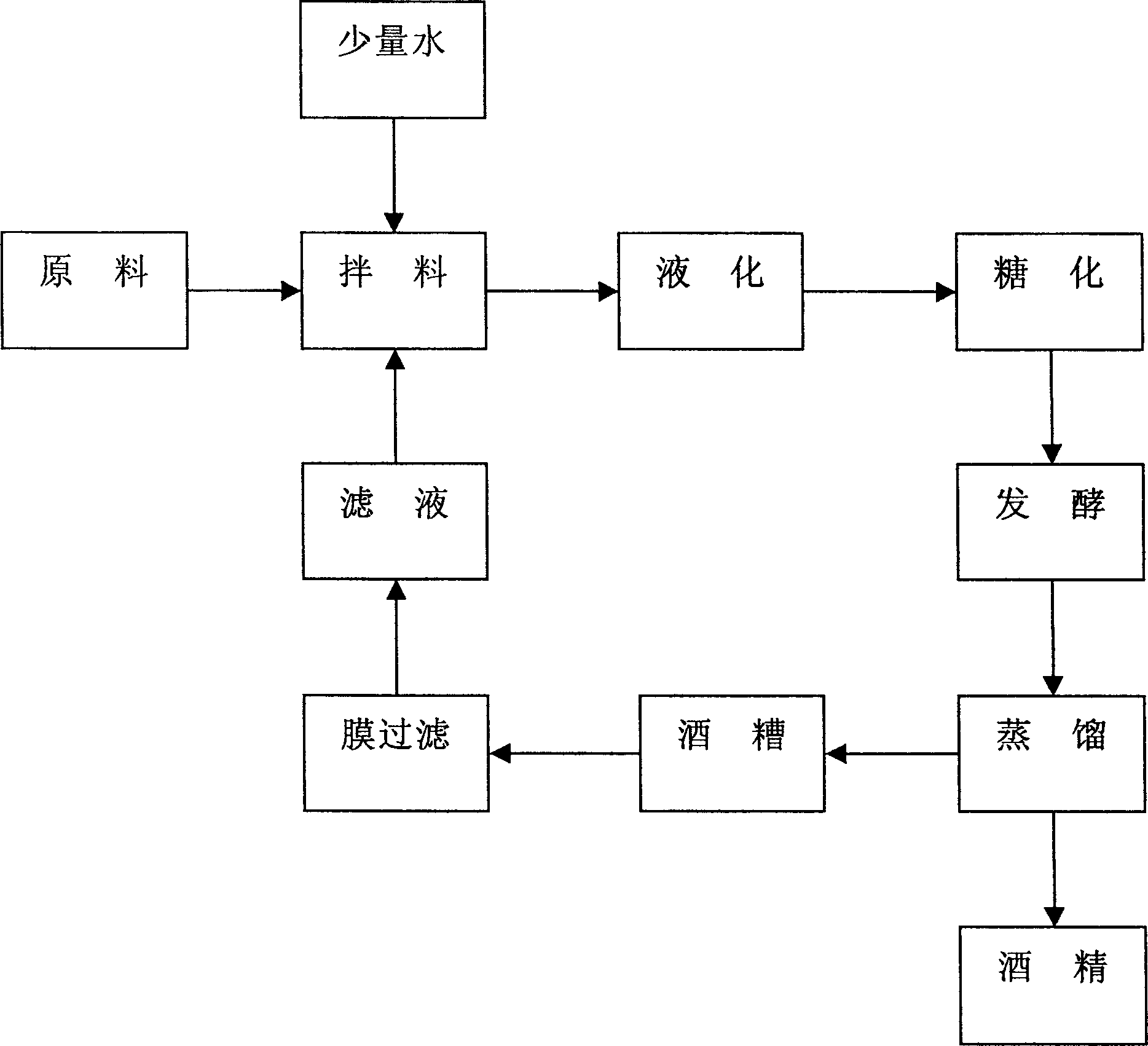

Image

Examples

Embodiment 1

[0018] Example 1: Corn is used as raw material for fermenting thick mash, and the conditions for membrane filtration of distiller's grains are: filter pore size: 0.8 micron; filter temperature: 98°C; working pressure: 0.1 MPa. The distiller's grains were reused in 4 batches to reach a dynamic balance; a total of 15 batches were filtered and reused, and the utilization rate of starch in each batch of alcohol thick mash fermentation was greater than or equal to 92.5%.

Embodiment 2

[0019] Example 2: Using cassava as raw material for fermenting thick mash, the conditions of distiller's grain liquid membrane filtration are: filter pore size: 1 micron; filter temperature: 80°C; working pressure: 0.08 MPa. The distiller's grains were reused in 3 batches to reach a dynamic equilibrium; a total of 15 batches were filtered and reused, and the utilization rate of starch in each batch of alcohol thick mash fermentation was greater than or equal to 93%.

Embodiment 3

[0020] Example 3: Dried melon and cassava were used as raw materials for fermenting concentrated mash, and the conditions for liquid membrane filtration of distiller's grains were: filter pore size: 2 microns; filter temperature: 90°C; working pressure: 0.15 MPa. The distiller's grains were reused after 5 batches to reach a balance; a total of 15 batches were filtered and reused, and the starch utilization rate of each batch of alcoholic thick mash fermentation was greater than or equal to 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com