Cone-disk clutch

A clutch and cone-disc technology, applied in the field of machinery, can solve the problems of insufficiency of the separation control mechanism, reduced manufacturing cost, large separation control force, etc., and achieves the effect of eliminating the following phenomenon, reducing the weight and achieving a good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

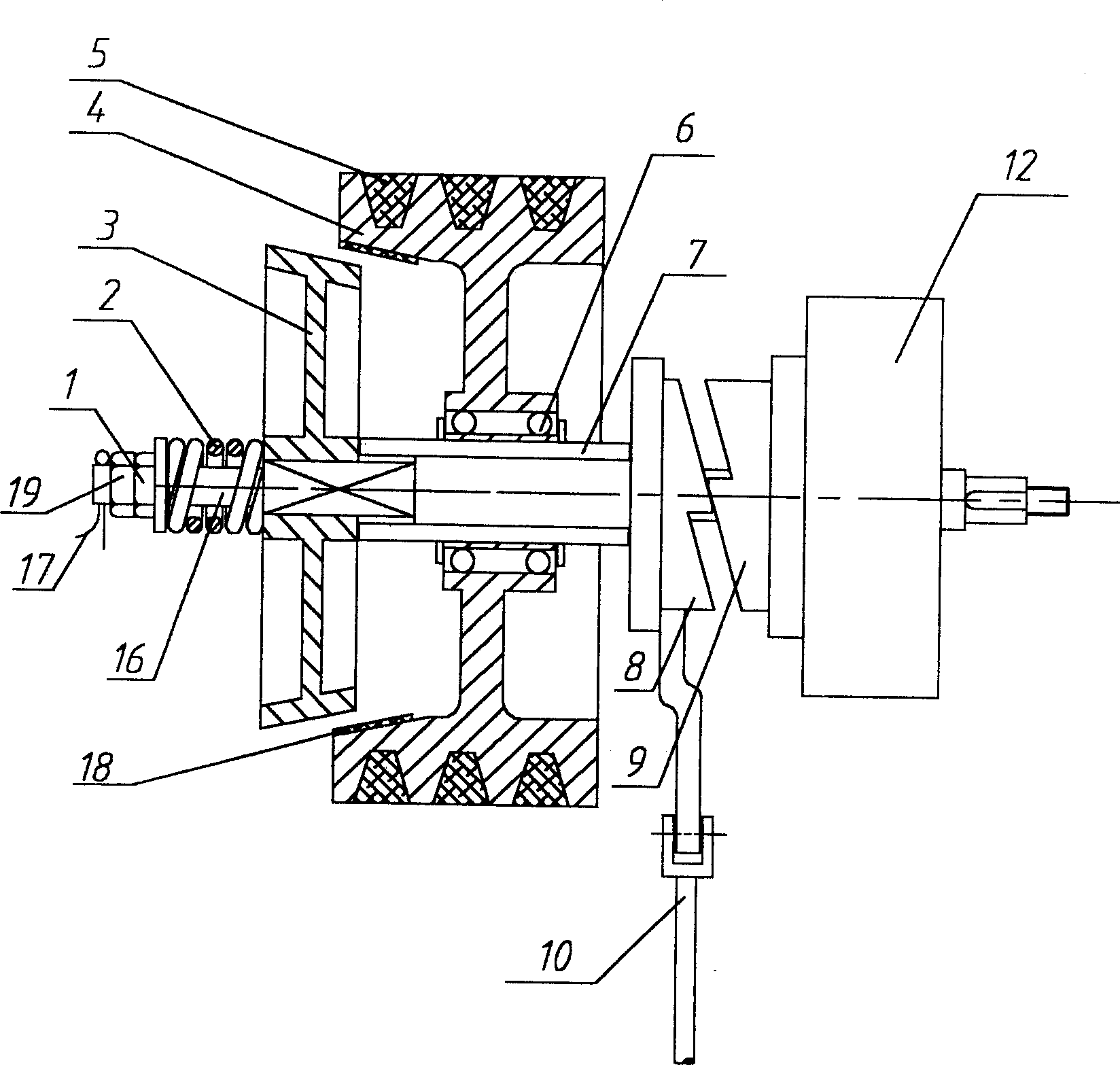

[0011] Embodiment 1, with reference to figure 1: The clutch is disengaged. The clutch part in the figure has been cut horizontally, 16 is the driven shaft, the driven disc 3 is connected with the driven shaft 16 through a spline, the driven disc 3 can move in series on the driven shaft 16, but cannot rotate freely; The disk 4 is arranged between the driven disk 3 and the separation operation mechanism, that is, the separation claw 8 and the bearing cover 9. The driving disk 4 is fixed to the driven shaft 16 through the bearing 6. There are retaining rings 20 on both sides of the bearing 6 to limit the displacement of the bearing 6. , the driving disc 4 can rotate freely on the driven shaft 16, and the power of the engine drives the driving disc 4 to rotate through a flexible transmission device such as a chain or a V-belt 5; , the opposite helical tooth surface meshes with the bearing cover 9 assembled on the gearbox, and the lower part of the separation claw is twisted with ...

Embodiment 2

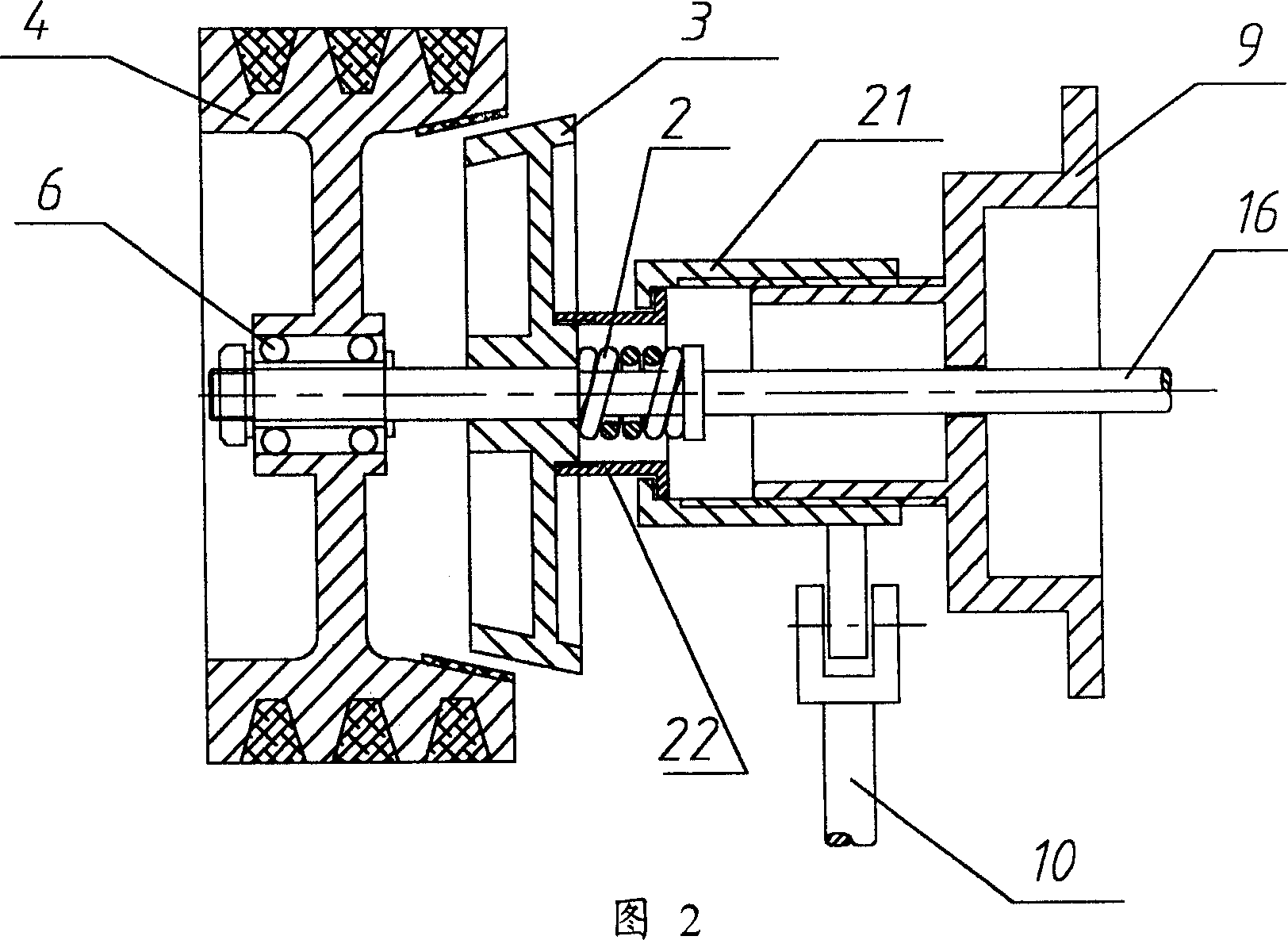

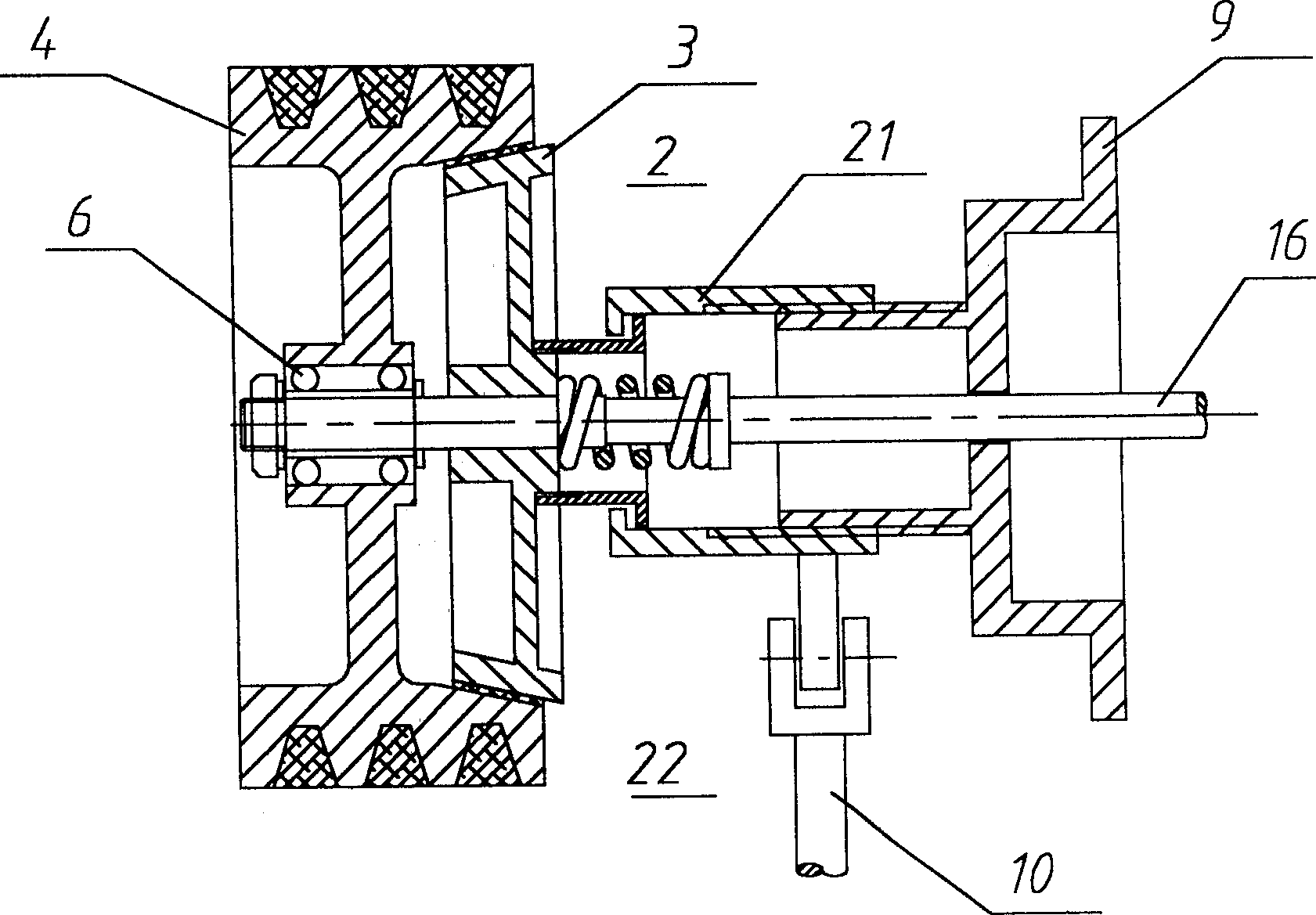

[0012] Embodiment 2, with reference to Fig. 2, 3: the driven disk 3 is arranged between the driving disk 4 and the separation control mechanism, and a screw sleeve 21 that can be twisted is connected in series on the driven shaft 16, and the outer circle or the inner circle of the screw sleeve 21 Processing is threaded, and there is also a bearing cap 9 that is sleeved on the driven shaft 16 but is fixed on objects such as a gear box or a frame corresponding to it on one side of the screw sleeve 21, and the inner circle of the bearing cap 9 Or the outer circle is also processed with the same thread as the screw sleeve 21, the screw sleeve 21 and the bearing cover 9 are screwed together through the thread similar to bolts and nuts, and the axial displacement of the screw sleeve 21 is realized by pulling the pull rod 10 on the screw sleeve 21 , there is a screw tube 22 on the driven disk 3 to fasten and fit with it, the screw tube 22 runs through the screw sleeve 21, and when the...

Embodiment 3

[0013] Embodiment 3, with reference to Figure 4 : The clutch is disengaged. A bow-shaped push rod 23 has a collar 24 and 25 at both ends, the collar 24 is set on the separation claw 8, and the collar 25 is set in the control groove of the driven disk 3; pulling the pull rod 10 and the separation claw 8, is received Under the action of the screw force, the bow-shaped push rod 23 will push the driven disc 3 away from the driving disc 4, and the clutch will be separated; otherwise, the pull rod 10 and the separation claw 8 will be released, and the separation claw 8 will no longer apply force to the bow-shaped push rod 23 , under the action of the force of the large spring 2 outside the driven disc 3, the bow-shaped push rod 23 moves freely toward the gearbox 12 side, the driven disc 3 is tightly pressed into the driving disc 4, and the clutch is combined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com