Stator slot holder with closed-loop stabilizer

A technology of stabilizing device and stator wire, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of reducing the winding space of the wire slot, reducing the occupancy rate of the stator coil wire slot, etc., to eliminate the Friction noise, elimination of wobble, effect of wobble elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] specific implementation plan

[0041] Embodiments of the present invention will be illustrated by the following description.

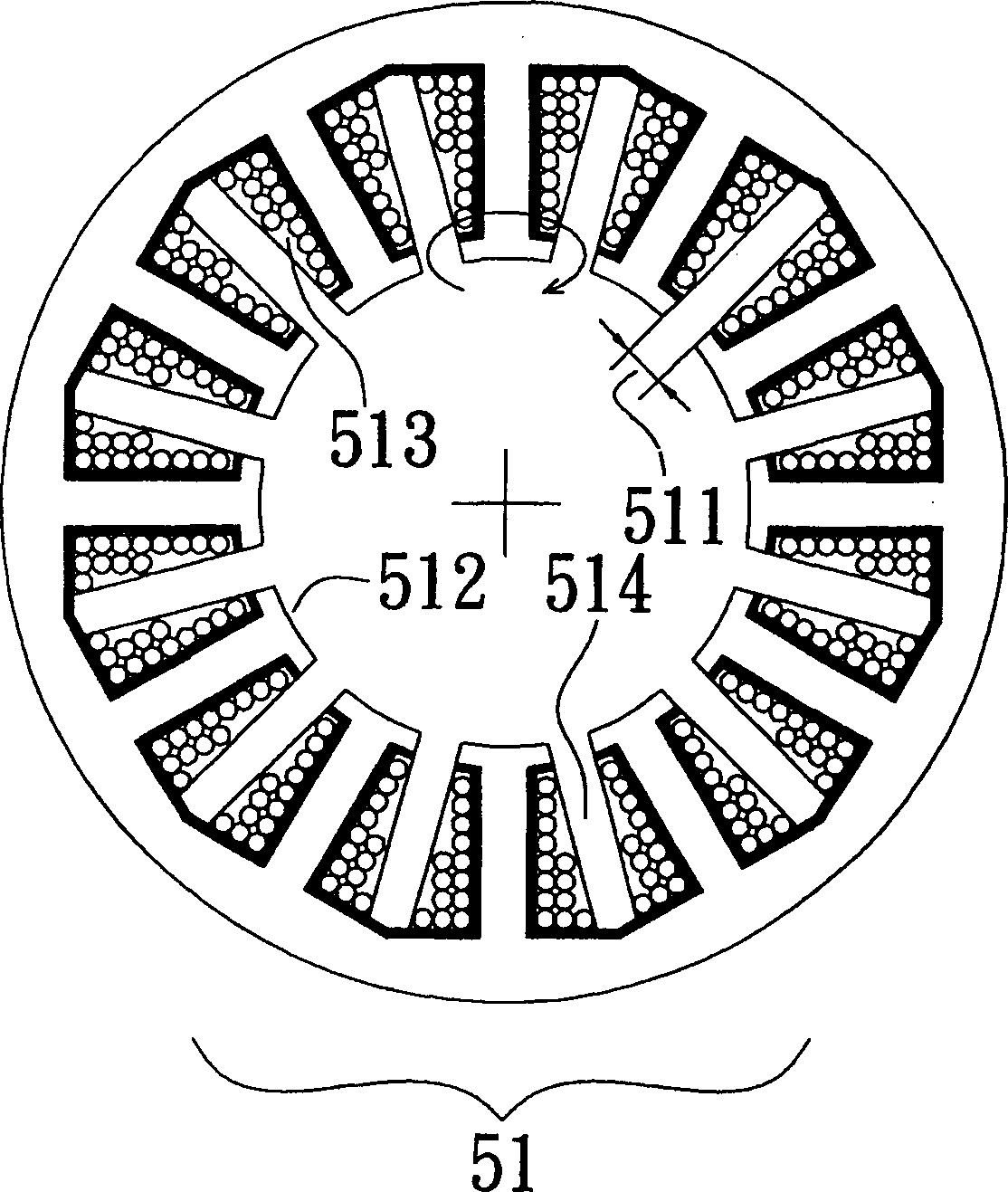

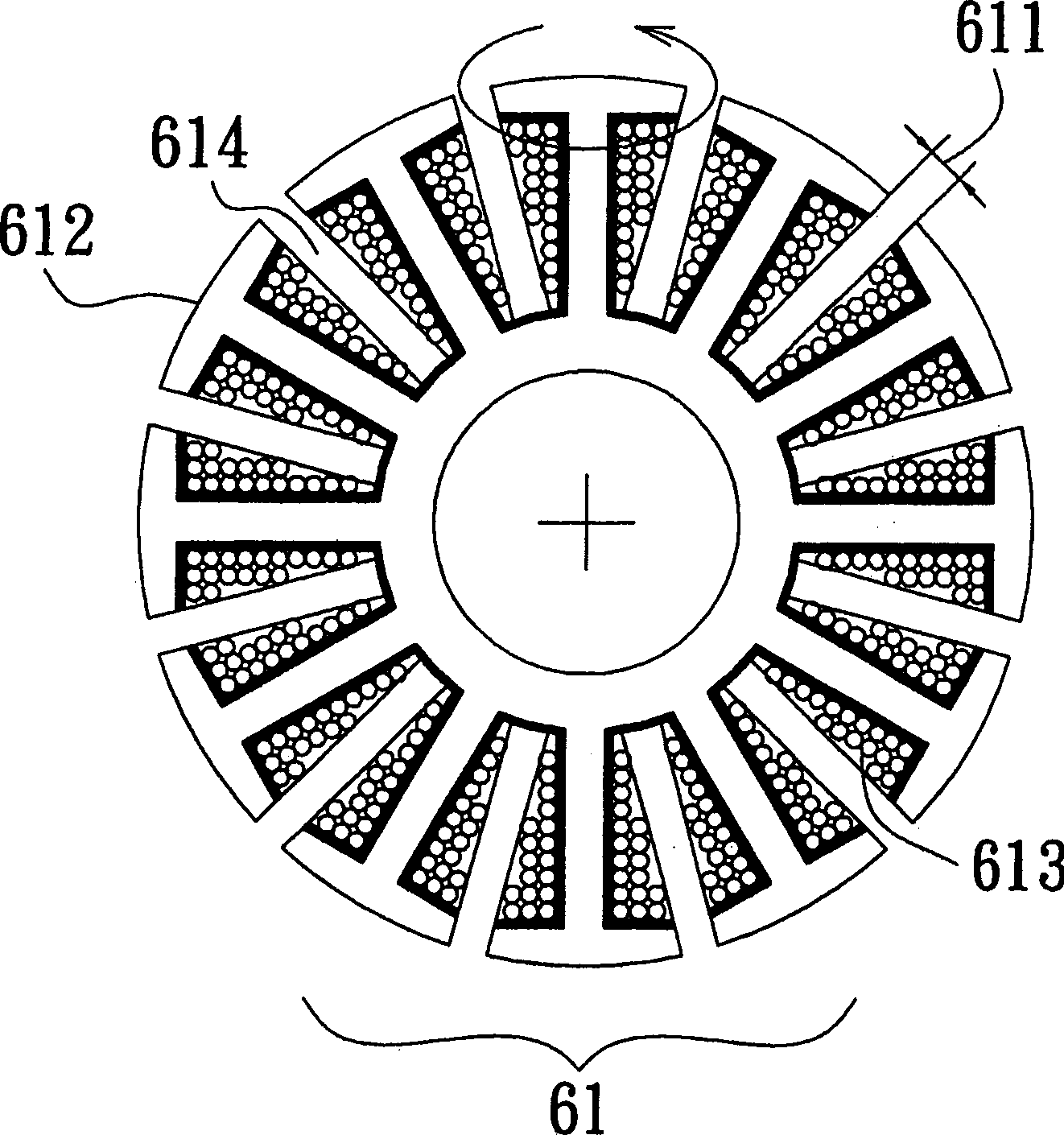

[0042] Please refer to Fig. 2 to Fig. 7, the stator slot seat 20 of the present invention has a ring-closed stabilizing device structure, including:

[0043] Most of the stator tooth magnetizers 31 with arc-shaped surfaces are separated from the mosaic grooves 211 and 212 of the annular magnetizer 21 of the stator.

[0044]A plurality of tooth slot seats 41, 418, 419, 420, which have: the back end 424 of the back side of the arc-shaped tooth surface 313 of the stator tooth magnetizer 31 can be engaged with; The left and right ends of the back end 424 form both side elevations 414, 415, 417, and the adjacent side elevations are formed correspondingly to each other and can be joined to each other's left and right elevations 414, 415, 417; The longitudinal vertical column 425 of the upper trunking seat 41, 420 provides the stator coil part 411 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com