Alcohol refining process for producing several products

A multi-product, alcohol technology, applied in the preparation of hydroxyl compounds, the preparation of organic compounds, the separation/purification of hydroxyl compounds, etc., can solve the problems of poor market adaptability, fewer product varieties, and excessive consumption, and achieve market competitiveness. The effect of improving the strength, accuracy and reliability of the equipment and reducing the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: edible alcohol technological step:

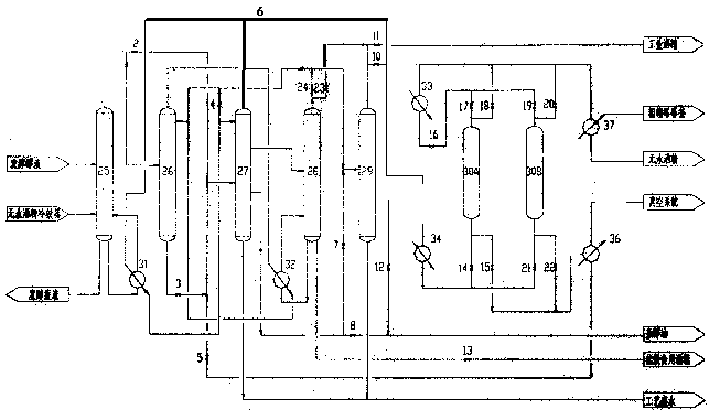

[0020] As shown in Figure 1, the thermally coupled rectification and refining process of edible alcohol is mainly composed of unit equipment such as crude distillation tower, fine tower, dealdehyde tower, methanol removal tower and recovery tower.

[0021] (1) The raw material liquid with an ethanol content of 5-30% enters the crude distillation tower 25. After vapor-liquid mass transfer separation, the waste liquid is discharged from the tower kettle and sent to the outside of the device area for processing. Open the valve 1, and the crude wine produced at the top of the tower is sent to the dealdehyde tower 26. The decompression operation pressure of the column is -0.02~-0.08Mpa, and the heating medium of the reboiler 31 is the top steam of the finishing column 27 . The main task of the crude distillation tower is to remove most of the water, organic acid and heavy component impurities brought along with the fermenta...

Embodiment 2

[0026] Press this embodiment, select raw material to be the fermented mash that contains ethanol 12% (V), according to the technical process described above, by the multi-product alcohol refining device shown in Fig. 1, can obtain alcohol degree and be 96.5% (V), Premium edible alcohol products with methanol content ≤ 2ppm, fusel oil content ≤ 2ppm, and oxidation time ≥ 40min. Embodiment 2: dehydrated alcohol technological step:

[0027] As shown in Figure 1, the anhydrous alcohol refining and dehydration process is mainly composed of crude distillation tower, fine tower, adsorption tower and other operating units.

[0028](1) The raw material liquid with a content of 5-30% enters the crude distillation tower, and after vapor-liquid mass transfer separation, the waste liquid is discharged from the tower kettle and sent to the outside of the device area for treatment. Open valve 2, and the crude wine extracted from the top of the tower is sent to the fine tower. The decompres...

Embodiment 3

[0036] Embodiment 3: Edible alcohol and dehydrated alcohol produce process step simultaneously:

[0037] As shown in Figure 1: It is mainly composed of unit equipment such as crude distillation tower, fine tower, dealdehyde tower, methanol removal tower, recovery tower and adsorption tower.

[0038] (1) The raw material liquid with an ethanol content of 5-30% enters the crude distillation tower, and after vapor-liquid mass transfer separation, the waste liquid is discharged from the tower kettle and sent to the outside of the device area for processing. Close valve 2, and the crude wine produced at the top of the tower is sent to the dealdehyde tower. The decompression operation pressure of the column is 0-0.08Mpa, and the heating medium of the reboiler of the crude column is the top steam and the anhydrous alcohol product vapor of the fine column. The main task of the crude distillation tower is to remove most of the water, organic acid and heavy component impurities brought...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com