Double mesopore molecular sieve and its preparation method

A molecular sieve and double mesoporous technology, which is applied in the fields of double mesoporous molecular sieve and its preparation, inorganic synthesis and catalysis science, can solve the problems of long reaction time, environmental pollution, complex processing steps, etc., and achieve simple operation, rich types and conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

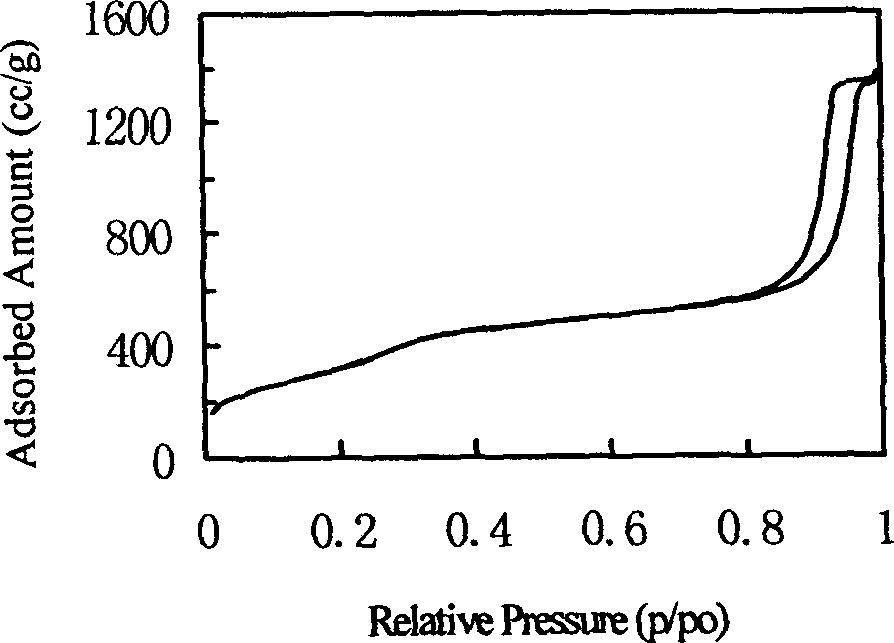

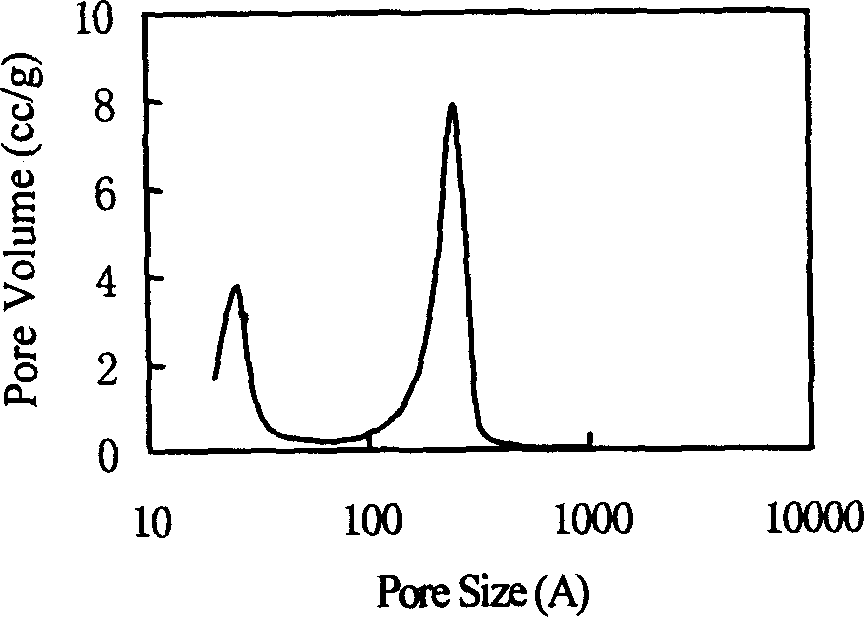

[0040]At a constant stirring speed, add a certain amount of ethyl tetrasilicate dropwise into the aqueous solution in which the surfactant TTAB is dissolved, and continue to stir for 5 minutes until the mixture is evenly mixed, and then add a given amount of concentrated solution dropwise under stirring. Ammonia, so that the pH of the system is 9.5, and the molar composition is obtained as SiO 2 : 0.185TTAB : 0.18NH 3 ·H 2 O: 100H 2 O mixture. After the mixture was continuously stirred at room temperature for 6 hours, it was centrifuged, washed, dried and ground to obtain a synthetic double mesoporous molecular sieve. Gradually raise the temperature to 550°C and bake for 6 hours in an air atmosphere to obtain a double mesoporous molecular sieve. Its typical N 2 Adsorption-desorption isotherms and corresponding pore distribution curves are shown in figure 1 . Example 2:

example 2

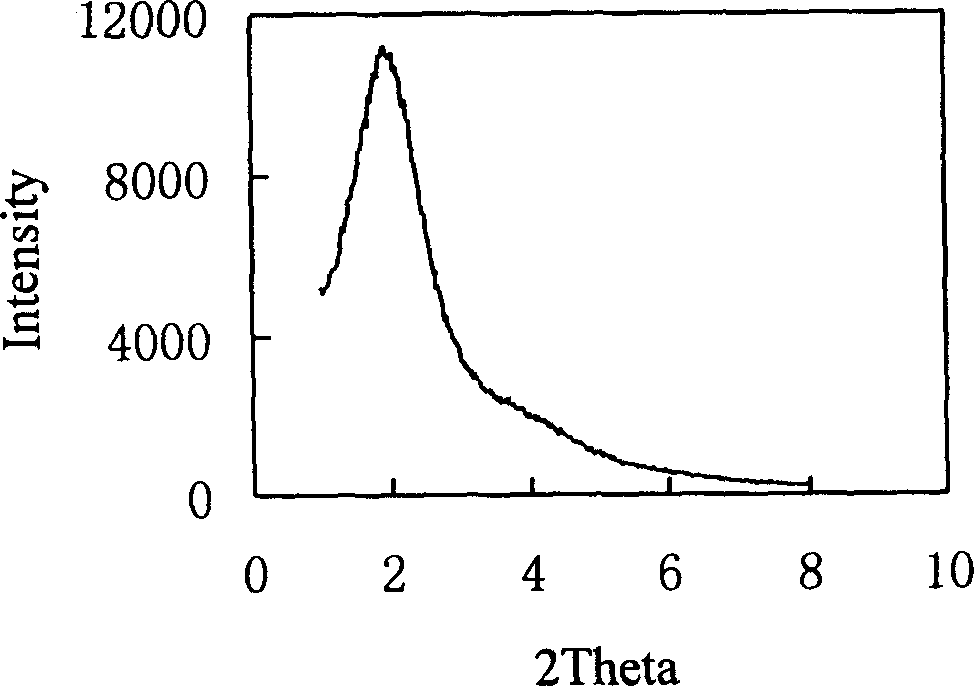

[0041] Dissolve a certain amount of surfactant CTAB in water at a constant stirring speed, raise the temperature slightly (30-40°C) to completely dissolve CTAB into a uniform and clear solution, and then add a certain amount of orthosilicate dropwise under stirring In the CTAB solution, continue to stir for 5 minutes until the mixture is evenly mixed, and finally add a given amount of concentrated ammonia water drop by drop under stirring, so that the pH of the system is 9.5, and the molar composition is obtained as SiO 2 : 0.185CTAB : 0.6NH 3 ·H 2 O: 100H 2 O mixture. After the mixture was continuously stirred at room temperature -40°C for 6 hours, it was centrifuged, washed, dried, and ground to obtain a synthetic double mesoporous molecular sieve. Gradually raise the temperature to 550°C and bake for 6 hours in an air atmosphere to obtain a double mesoporous molecular sieve. Its typical XRD pattern, TEM photo, N 2 Adsorption-desorption isotherms and corresponding pore ...

example 3

[0042] Dissolve a certain amount of surfactant CTAB in water at a constant stirring speed, raise the temperature slightly (30-40°C) to completely dissolve CTAB into a uniform and clear solution, and then add a certain amount of tetraethyl orthosilicate dropwise under stirring In the CTAB solution, continue to stir for 5 minutes, then add a quantitative amount of co-solvent mesitylene (TMB), stir until the mixture is evenly mixed, and finally add a given amount of strong ammonia dropwise under stirring, so that the pH of the system is 9.5, to obtain Molar composition as SiO 2 : 0.185CTAB : 0.32TMB : 0.6NH 3 ·H 2 O: 100H 2 O mixture. After the mixture was continuously stirred at room temperature -40°C for 6 hours, it was centrifuged, washed, dried, and ground to obtain a synthetic double mesoporous molecular sieve. Gradually raise the temperature to 550°C and bake for 6 hours in an air atmosphere to obtain a double mesoporous molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com