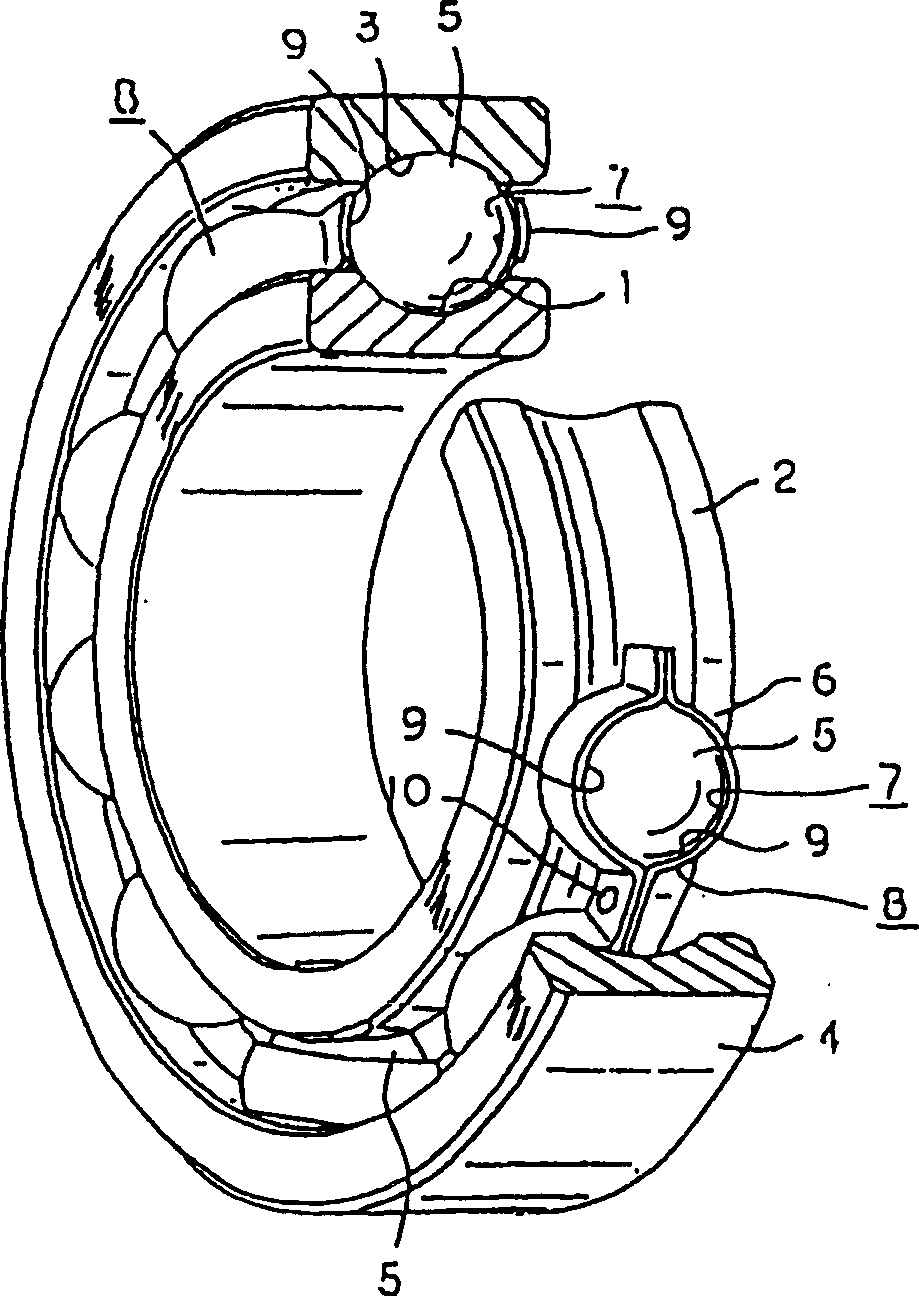

Ball bearing

A technology of ball bearings and rails, which is applied in the field of ball bearings, can solve problems such as poor friction coefficient of lubricant intake, fluctuation of ball bearing friction torque, friction sound and friction sound, etc., to reduce fretting wear damage, reduce bearing torque, reduce Effect of Small Contact Surface Pressure Difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

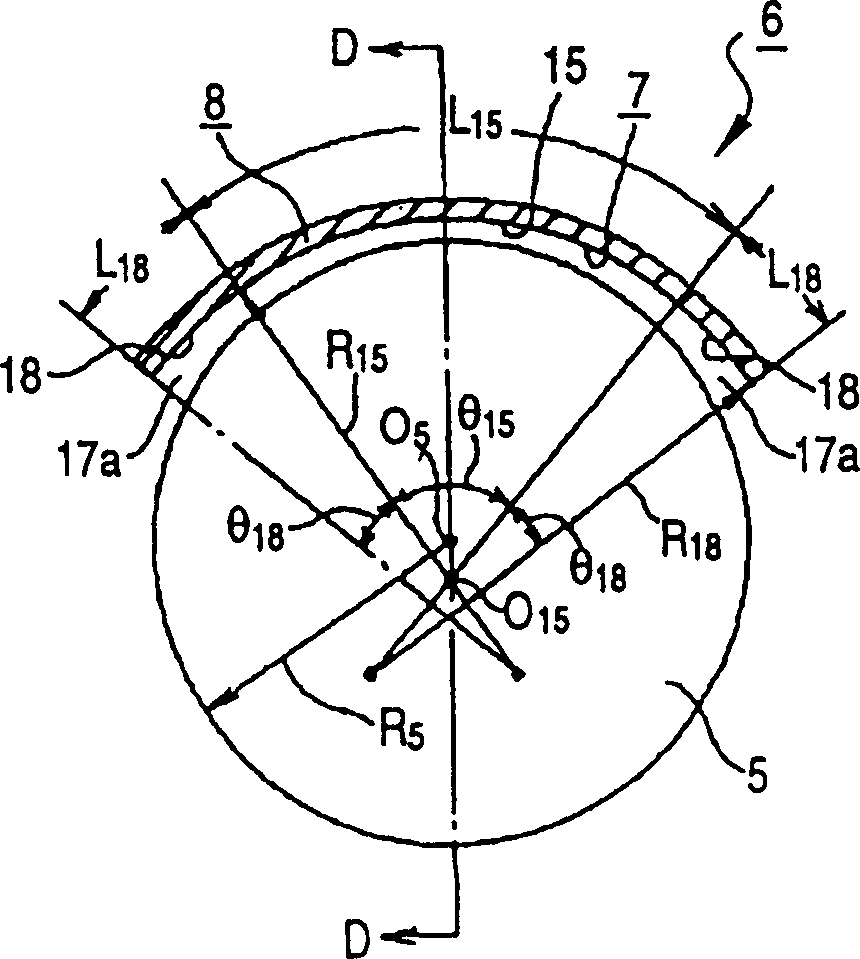

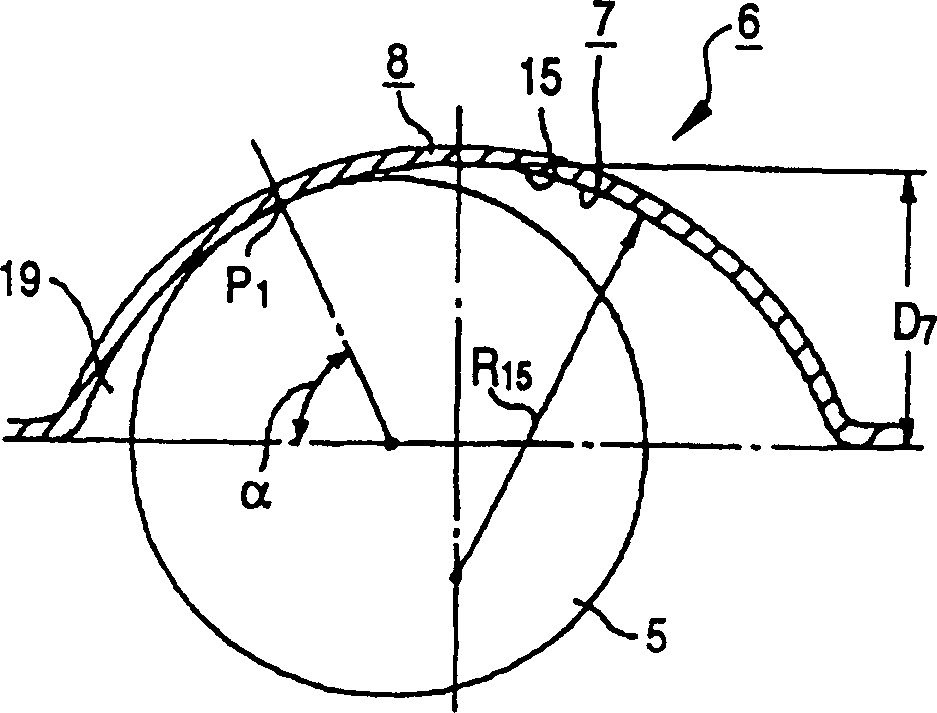

Method used

Image

Examples

Embodiment 1~11, comparative example 1~5

[0116] Table 1, Table 2 and Table 3 show the grease composition and properties of Examples 1-11 and Comparative Examples 1-5. In addition, assuming that the total amount of lithium soap and base oil is 950 g, 50 g of additives (carbonic acid, antioxidant, rust inhibitor, metal deactivator, etc.) are added thereto to form a grease composition with a total amount of 1000 g. The same table also shows the dynamic viscosity and mixing consistency of the base oil at 40°C. The preparation method is: dissolve hydroxystearic acid in various non-polar lubricating oils, make it react with lithium hydroxide to form lithium soap, heat it to above 210°C, dissolve it in each polar-based lubricating oil, Keep it at 200°C for about 60 minutes, then cool it down to 140°C at a rate of 1°C / min, and then add the additional base oil (synthetic hydrocarbon oil + polar containing oil) heated to 140°C Base lubricating oil), processed with a three-stage rolling mill to obtain a grease composition.

...

Embodiment 1

[0120] Example 1: Groove R of the inner ring track = 51.75%, groove R of the outer ring track = 53.0%

Embodiment 2

[0121] Example 2: Groove R of the inner ring track = 51.5%, groove R of the outer ring track = 52.5%

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com