Cloth decoration edge forming device constituted from sawtooth stitch sewing machine

A sewing machine and stitching technology, applied in the field of mutual hooking, can solve the problems of poor operability and productivity, inability to stretch the thread, difficult to sew evenly, etc., and achieve the effect of stable shape and avoiding disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

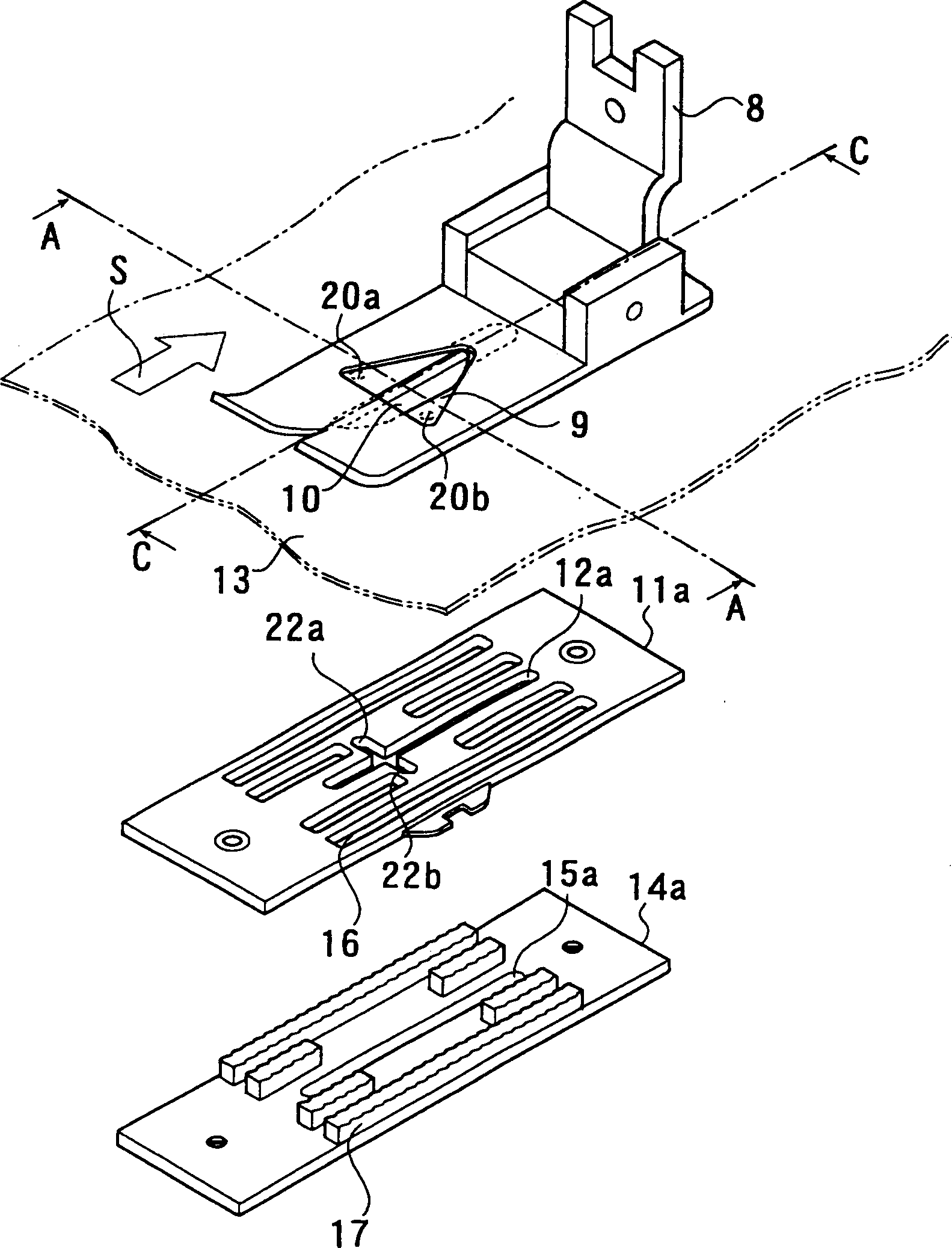

[0067] Next, an embodiment of the present invention will be described with reference to the drawings. The following is an embodiment of the present invention, but the present invention is not limited thereto. Arrow S in the figure indicates the direction of cloth feeding. figure 1 It is an exploded perspective view showing main components of an embodiment of the present invention.

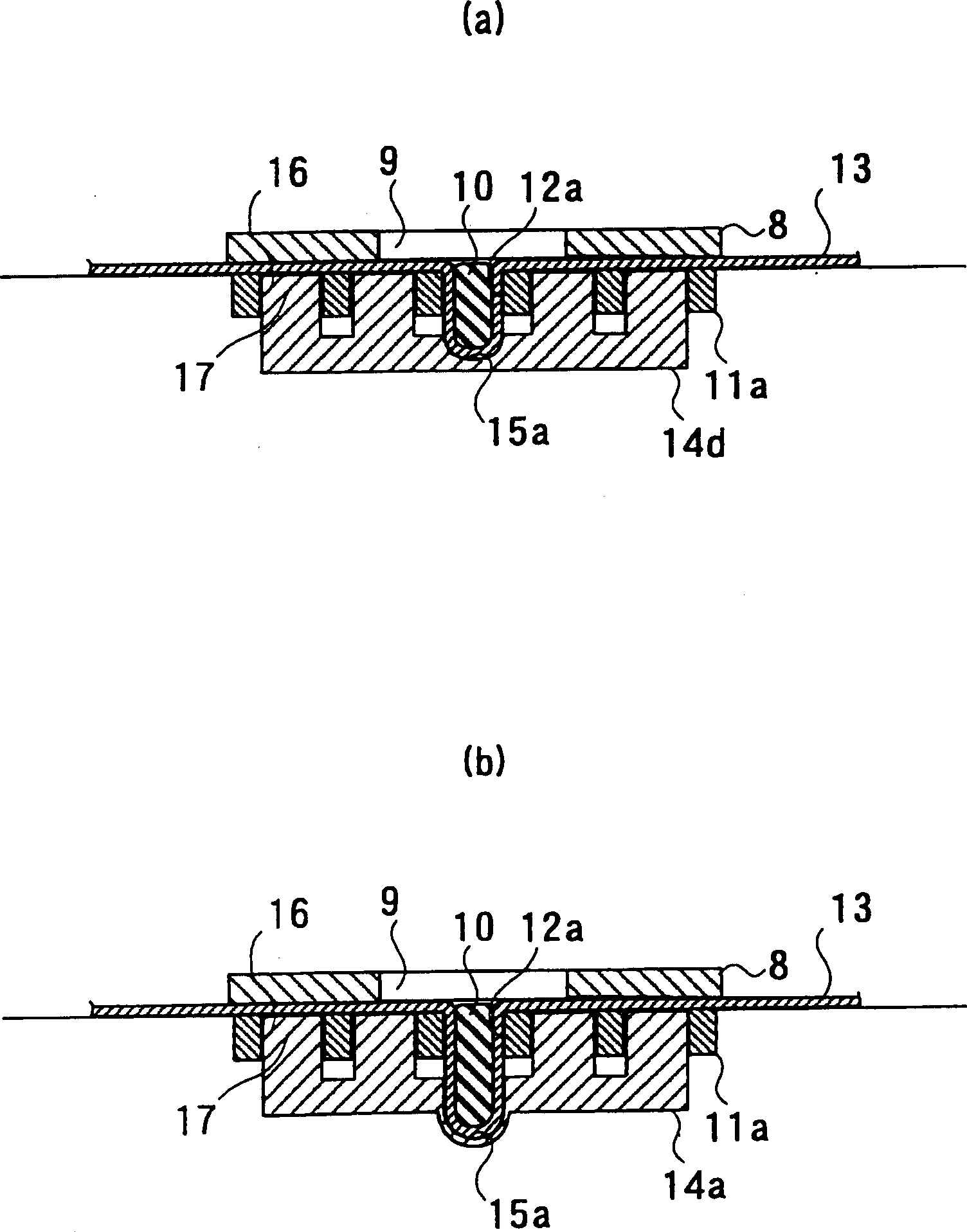

[0068] like figure 1 As shown, in the zigzag sewing machine of this embodiment, there are presser foot 8, needle plate 11a and cloth feeding teeth 14a as the parts having the characteristic structure of the present invention.

[0069] The presser foot 8 has a needle drop portion 9 at the center. In addition, a guide plate 10 is arranged vertically below the presser foot 8 .

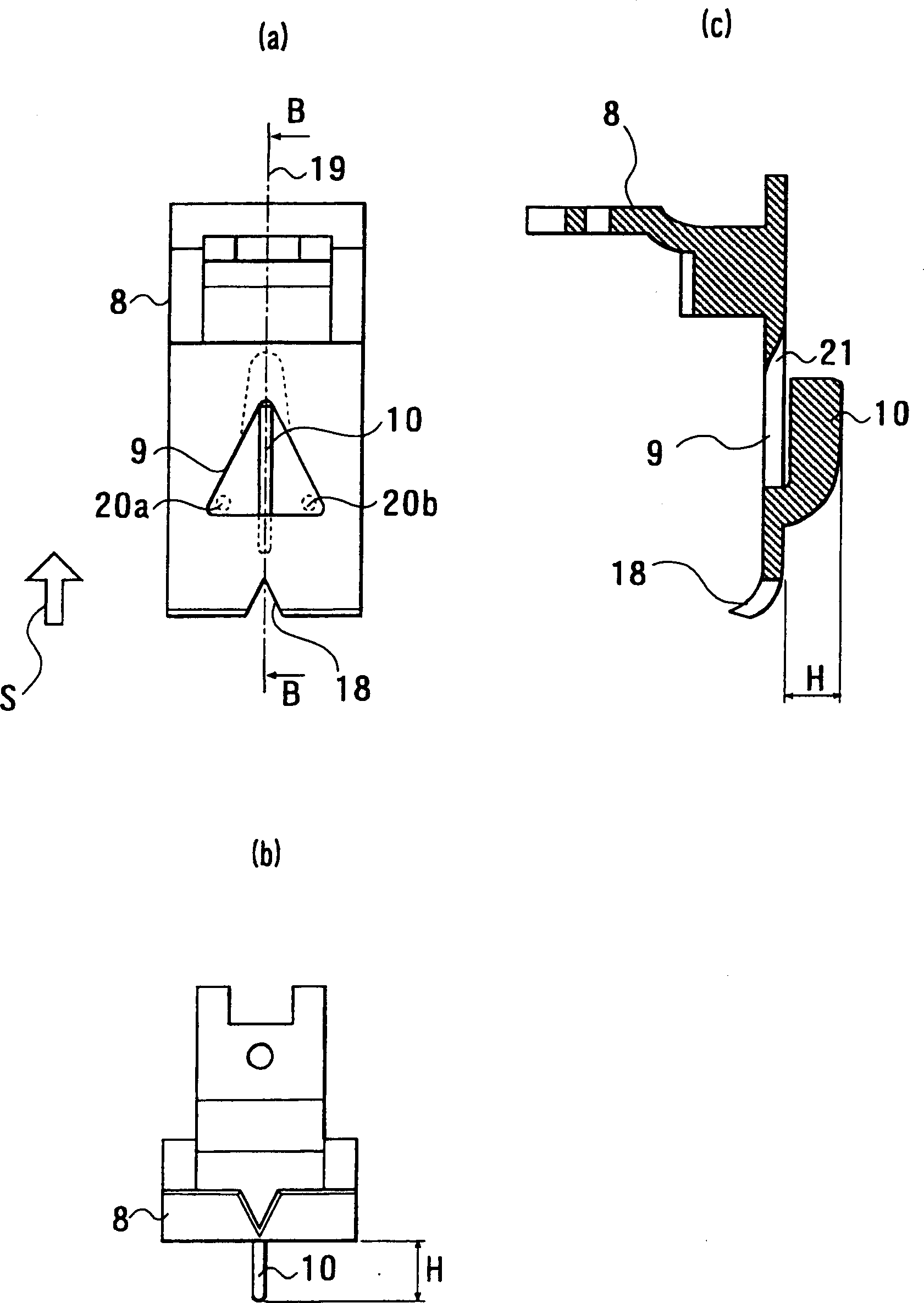

[0070] Here, refer to figure 2 The structure of the presser foot 8 will be described. exist figure 2 Among them, (a) is a plan view of the presser foot 8, (b) is a front view, and (c) is a B-B sectional view.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com