Electric machines

A current and armature winding technology, applied in the direction of synchronous machines, electromechanical devices, electrical components, etc., can solve problems such as not having advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

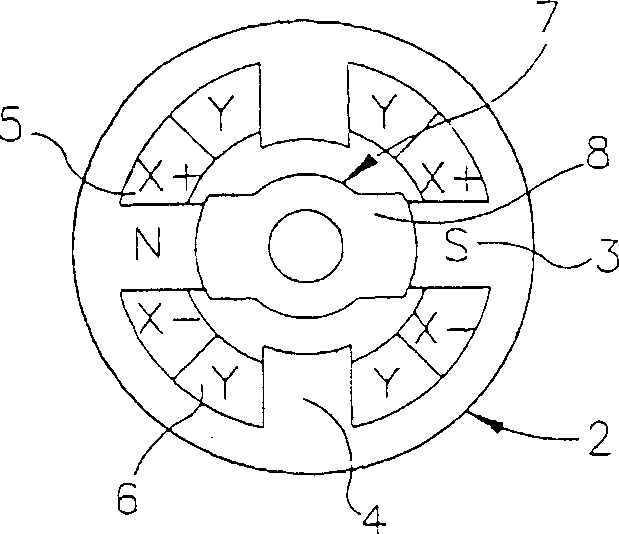

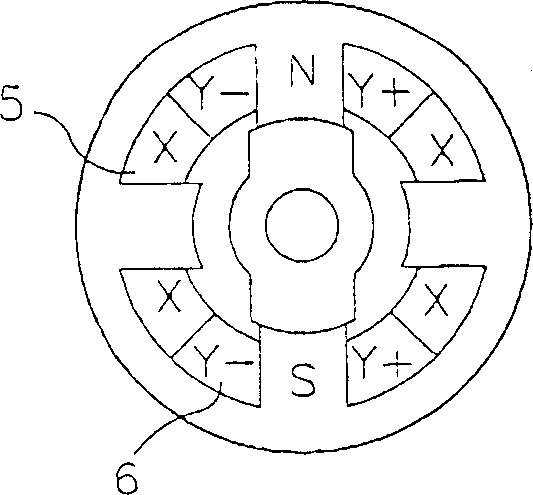

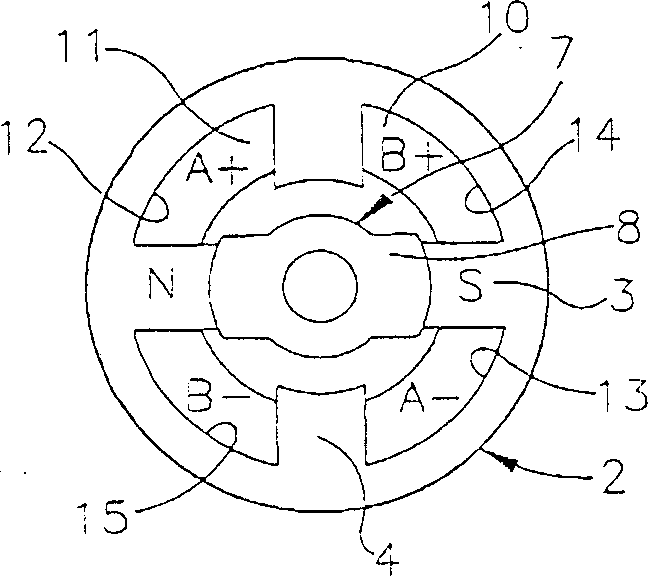

[0019] Embodiments of the invention will be described below with reference to a flux-switching motor having a four-pole stator and a two-pole rotor, wherein the stator has a field winding 10 and an armature winding 11 divided into two coils 24 and 25, these The coils are tightly coupled and wound such that diametrically opposed portions of the coils are located in diametrically opposed stator slots. For further explanation, the two armature coils are referred to as A 1 and A 2 .

[0020] In the circuit of FIG. 5, field winding 10 is connected in parallel with armature coils 24 and 25 and capacitor 57 so that the currents through field winding 10 and armature coils 24 and 25 are different. Powering the circuit from an AC source 58 by means of a rectifier bridge 59, the switch control circuit 60 alternately powers the armature coils 24 and 25 to provide magnetomotive forces acting in opposite directions for motor rotation. In this case, the circuit arrangement has two switche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com