Sports milk and its production method

A milk and sports technology, applied in the field of milk, can solve the problem that nutritional components and nutritional functions cannot meet nutritional needs, and achieve the effects of high digestibility, easy digestion and absorption, and increased muscle mass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

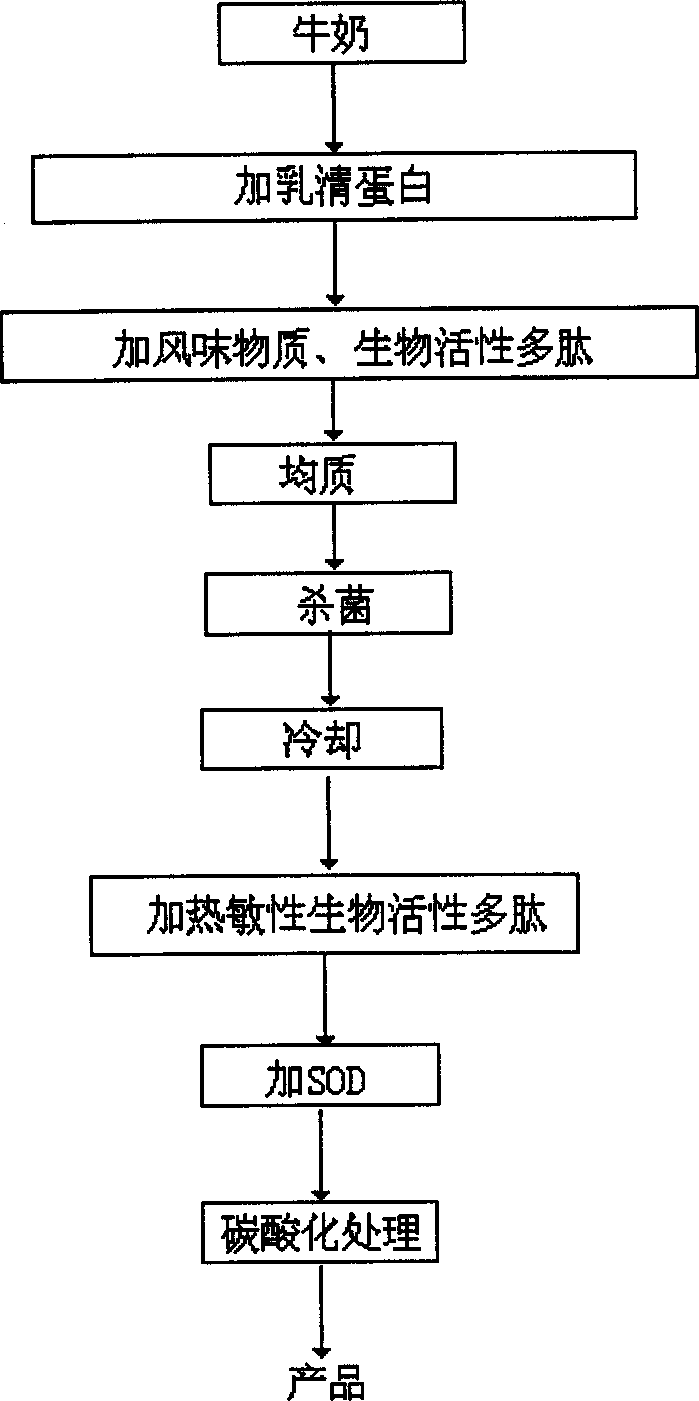

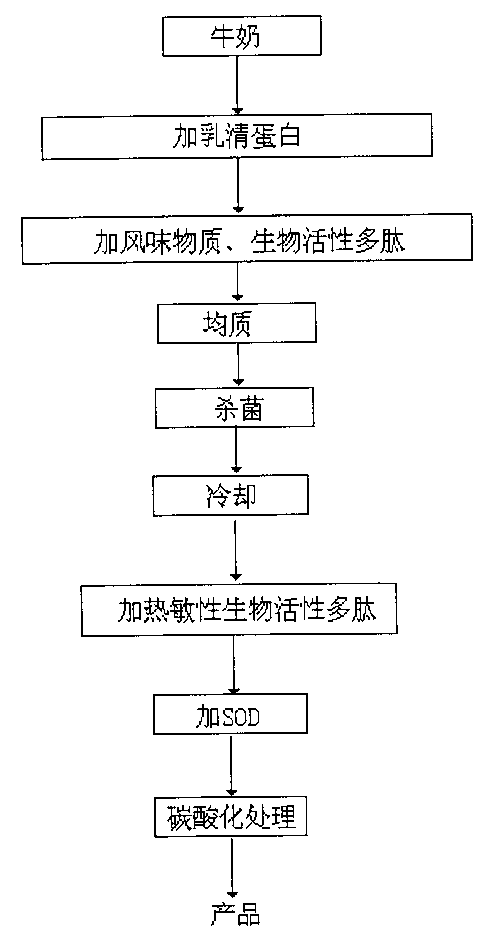

[0041] Depend on figure 1 Visible, preparation method of the present invention comprises the following steps:

[0042] (1) Add whey protein to milk and stir for 5-10 minutes;

[0043] (2) Add flavoring substances and non-heat-sensitive biologically active polypeptides, and stir for 5-10 minutes;

[0044] (3) Homogenize under the conditions of 60-80°C and 150-300bar in the homogenizer, or pass through two-stage homogenization, and the pressures are 30-50bar and 100-250bar respectively;

[0045] (4) Sterilize for 3s-30min under the condition of 65-140°C;

[0046] (5) Cool to 4-25°C, add SOD, and stir for 5-10 minutes to obtain the sports milk of the present invention.

[0047] According to the present invention, for the heat-sensitive biologically active polypeptide, the heat-sensitive biologically active polypeptide can be added in step (5) to prevent the heat-sensitive biologically active polypeptide from being inactivated and losing its biological activity.

[0048] Accor...

Embodiment 1

[0078] The preparation process is as follows:

[0079] (1) Add whey protein to milk and stir for 5 minutes;

[0080] (2) Add casein hydrolyzate and stir for 5 minutes;

[0081] (3) Homogenize in a homogenizer at 60°C and 150bar;

[0082] (4) Sterilize for 30 minutes at 65°C;

[0083] (5) Cool to 4°C, add SOD, stir for 5 minutes, and carry out carbonation treatment to obtain a carbonated sports milk.

[0084] project

indicators

Fat

0.40%

5.00%

non-fat milk solids

11.0%

SOD vitality

3.5×10 6 U / L

Raw material requirements

Amount added

milk

Fat ≥ 1.0%, protein ≥ 1.5%, non-fat milk solids ≥ 6.0%

93.9%

Protein ≥17%

5.0%

whey protein hydrolyzate

Protein ≥34%

0.5%

SOD

0.5%

Sweet Orange Flavor

0.1%

[0085] The preparation process is as follows:

[0086] (1) ...

Embodiment 5

[0099] The preparation process is as follows:

[0100] (1) Add whey protein to milk and stir for 7 minutes;

[0101] (2) Secondary homogenization in a homogenizer at 75°C and 50bar / 250bar;

[0102] (3) Sterilize for 15 seconds at 100°C;

[0103] (4) Cool to 18°C, add wheat protein hydrolyzate, stir for 9 minutes, add SOD, stir for 10 minutes to obtain sports milk.

[0104] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com