Zinc borate, and production and use thereof

A technology represented by zinc borate, applied in the field of new zinc borate, can solve problems such as poor insulation, deterioration of electrical properties, and dielectric breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

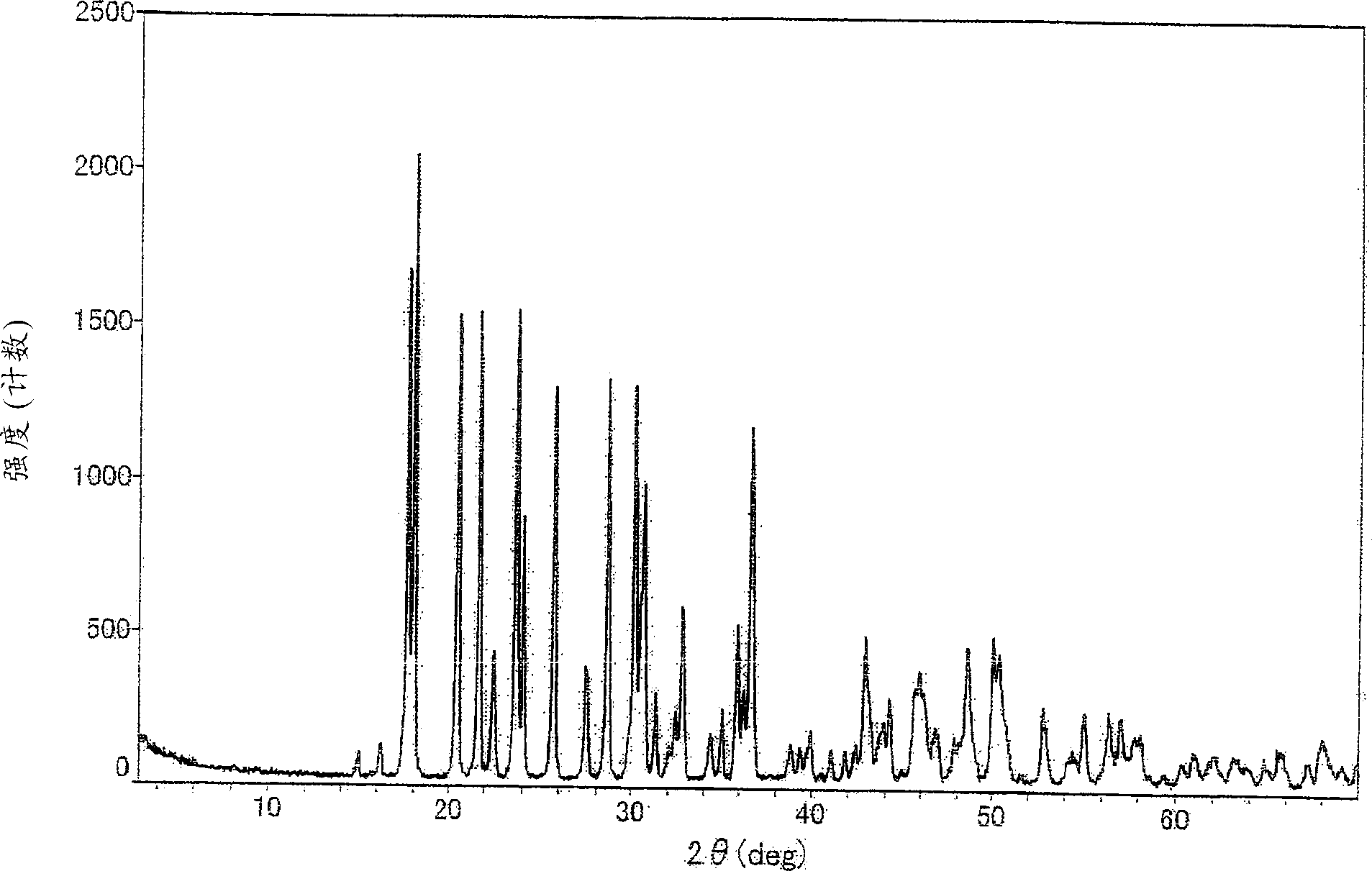

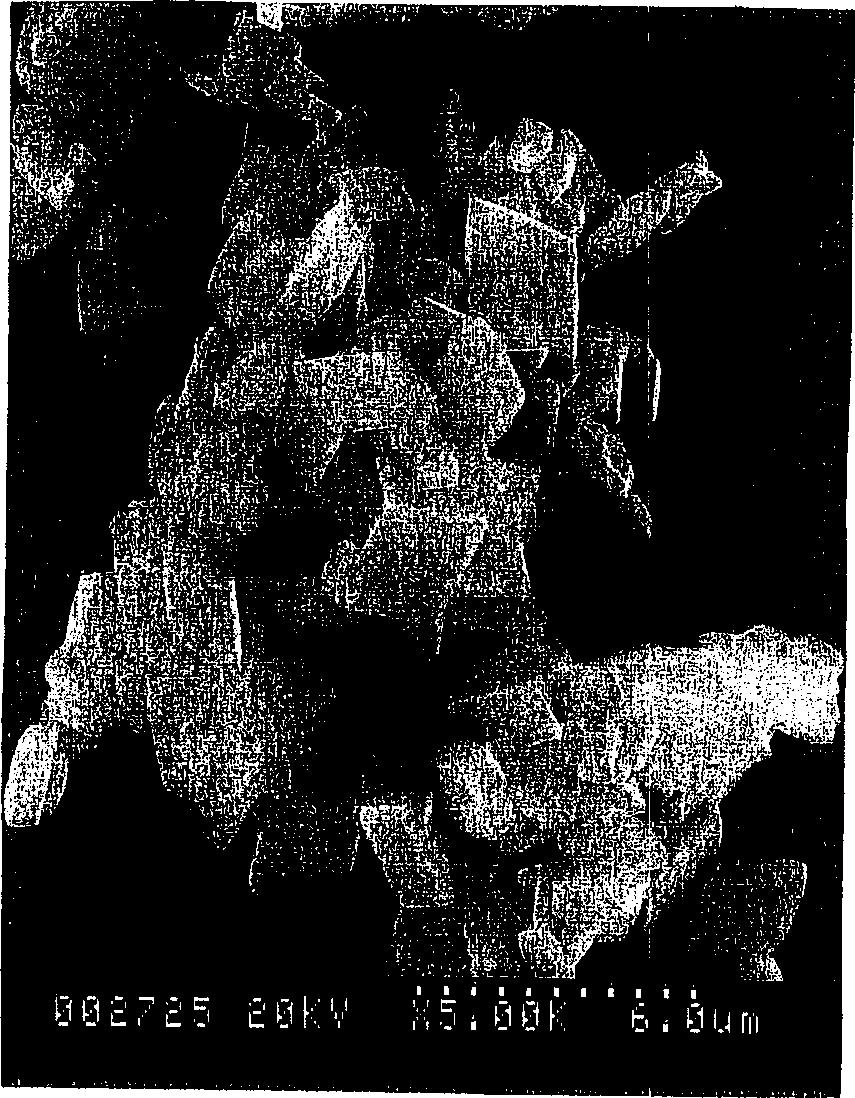

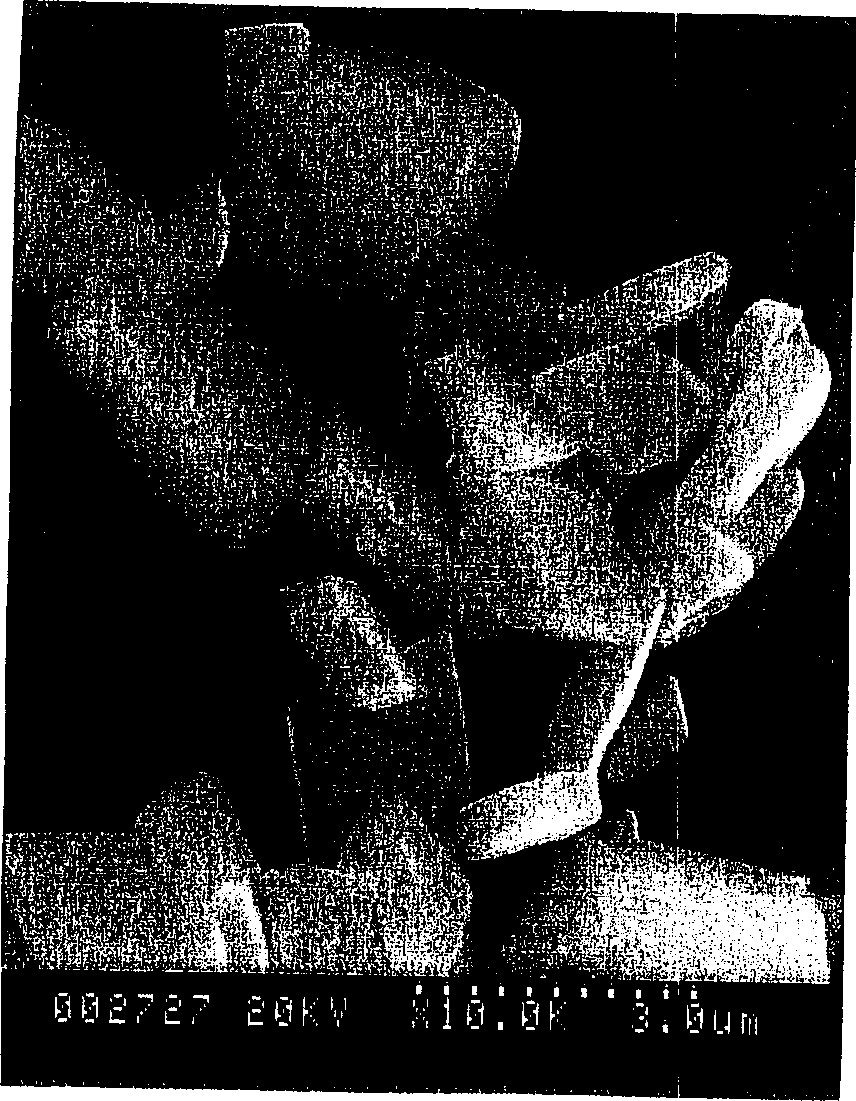

[0189] By adding 72.5 grams of boric acid (B 2 o 3 content of 56.3%) was dissolved in 1000 ml of pure water to prepare an aqueous solution. Add 96.0 grams of zinc white (ZnO content is 99.4%) and 217.5 grams of boric acid (B 2 o 3 content is 56.3%), stir and mix together to make B 2 o 3 The molar ratio of / ZnO was 2.0. Then, the solution was stirred and reacted at 60° C. for 90 minutes. The solution was further stirred and reacted at 90°C for 4 hours. The resulting product was filtered, washed with water, and then dried at 105°C to obtain zinc borate (sample A-1). Table 3 shows the chemical composition and properties of the thus obtained zinc borate (sample A-1), figure 1 shows its X-ray diffraction pattern, figure 2 with image 3 is its scanning electron microscope image.

Embodiment 2

[0191] By adding 72.5 grams of boric acid (B 2 o 3 Content is 56.3%) is dissolved in 1000 milliliters of pure waters to prepare the aqueous solution, has added 1.25 grams of zinc borates (2ZnO 3B 2 o 3 3.5H 2 O) as future seeds. Add 95.7 grams of zinc white (ZnO content is 99.4%) and 217.5 grams of boric acid (B 2 o 3 content is 56.3%), stir and mix together to make B 2 o 3 The molar ratio of / ZnO was 2.0. Then, the solution was stirred and reacted at 60° C. for 90 minutes. The solution was further stirred and reacted at 90°C for 4 hours. The resulting product was filtered, washed with water and then dried at 105°C to obtain zinc borate (sample A-2). Table 3 shows the chemical composition and properties of the thus obtained zinc borate (sample A-2), Figure 4 shows its X-ray diffraction pattern, Figure 5 is its scanning electron microscope image.

Embodiment 3

[0193] By adding 72.5 grams of boric acid (B 2 o 3 content of 56.3%) was dissolved in 1000 ml of pure water to prepare an aqueous solution. Add 95.7 grams of zinc white (ZnO content is 99.4%) and 217.5 grams of boric acid (B 2 o 3 content is 56.3%), stir and mix together to make B 2 o 3 The molar ratio of / ZnO was 2.0. Then, the solution was stirred and reacted at 45°C for 120 minutes. The solution was further reacted with stirring at 90°C for 4 hours. The obtained product was filtered, washed with water and dried at 105°C to obtain zinc borate (sample A-3). Table 3 shows the chemical composition and properties of the thus obtained zinc borate (sample A-3), Image 6 shows its X-ray diffraction pattern, Figure 7 An electron micrograph of it is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com