Internally heating baking oven

A frying machine and internal heating technology, applied in baking, food science, application, etc., can solve the problems of difficult to ensure the quality of frying, complicated and loose structure, and pollute the environment, so as to improve the quality of frying products and simplify the structure The effect of tightening and not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

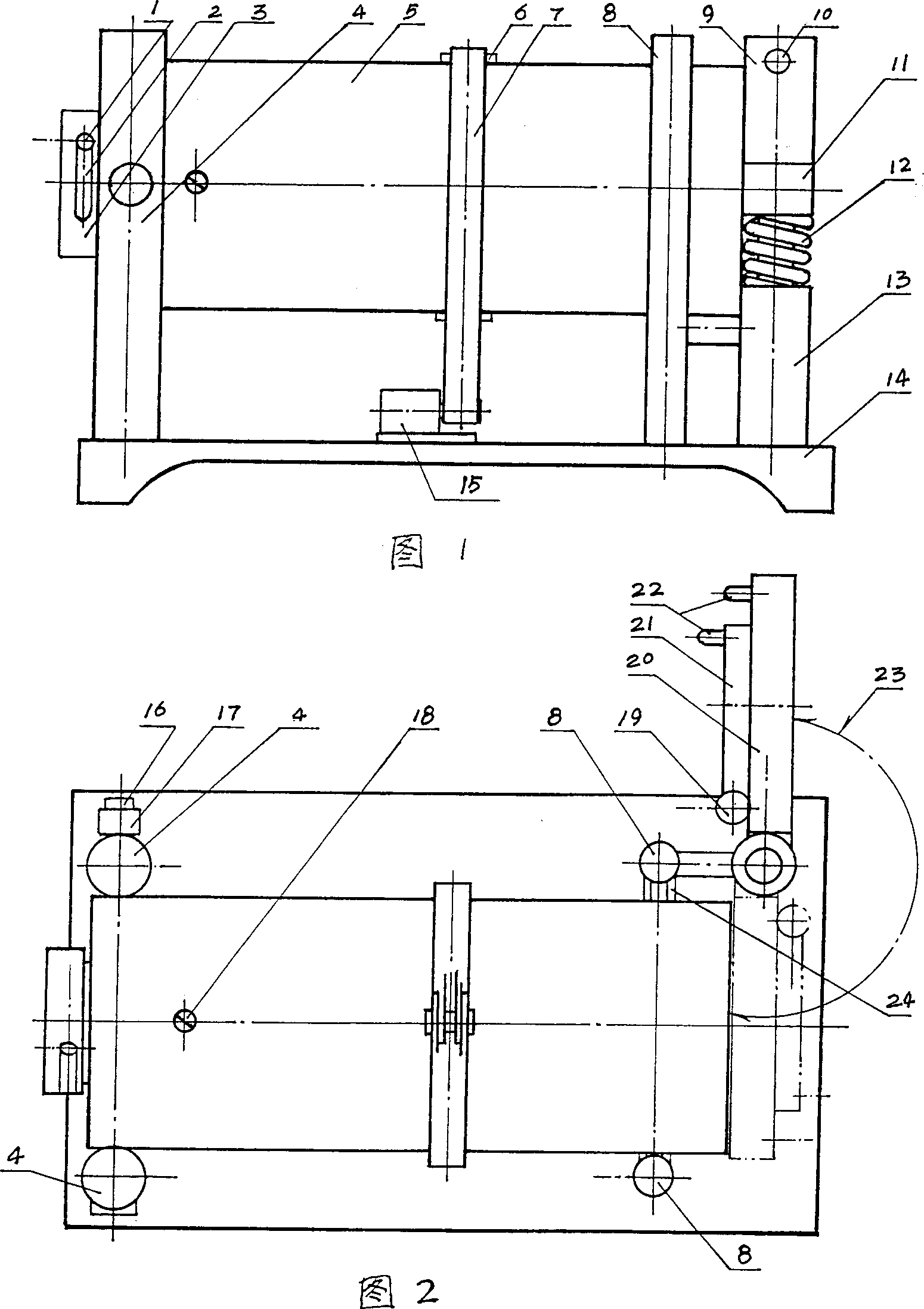

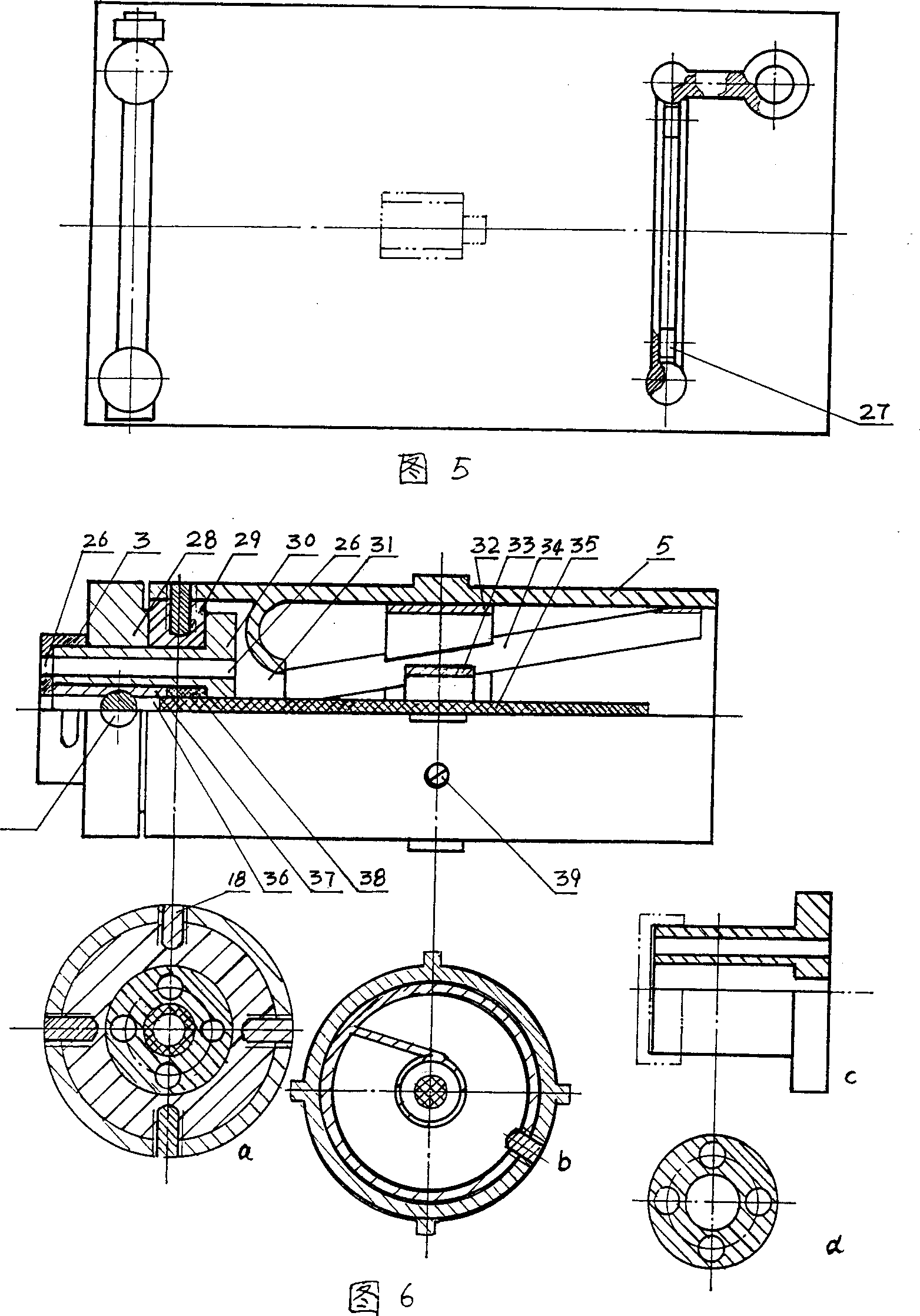

[0019] 6, the transition mechanism is formed by a hollow shaft 30 fastened by a pin-shaped bolt 16 with a nut 17, an outer ring 28, a cavity plug 37, a heat insulating sleeve 38 and an inner ring 29 that is looped on the hollow shaft 30. One end is inserted and held in the heating mechanism 35 in the heat-insulating sleeve 38, mainly in contact with the heat-insulating sleeve 38, which can reduce heat and save energy consumption.

[0020] The electric wire of heating mechanism can pass through wire hole 36 to pass. The drum 5 is fixed on the inner ring 29 by bolts 18. There is a trumpet-shaped inner roll mouth 31 inside the drum, and a cage-shaped mixing board 34 jointly formed by an outer yoke ring 32 and an inner yoke ring 33. Material plate, and by bolt 39 and roller fixed installation. The mixing plate 34 also can be directly welded on the inwall of the tube 5 (but it is unfavorable for cleaning the tube inner chamber, if the tube 5 is designed as a big pot-shaped tube wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com