Apparatus for treating used tyre

A kind of equipment and technology of waste rubber, which is applied in the direction of grain processing, tires, filter and sieve, etc., can solve the problem that waste rubber products are not suitable for reuse, achieve the goal of saving and utilizing renewable resources, solving the problem of waste tire treatment, and reducing the consumption of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

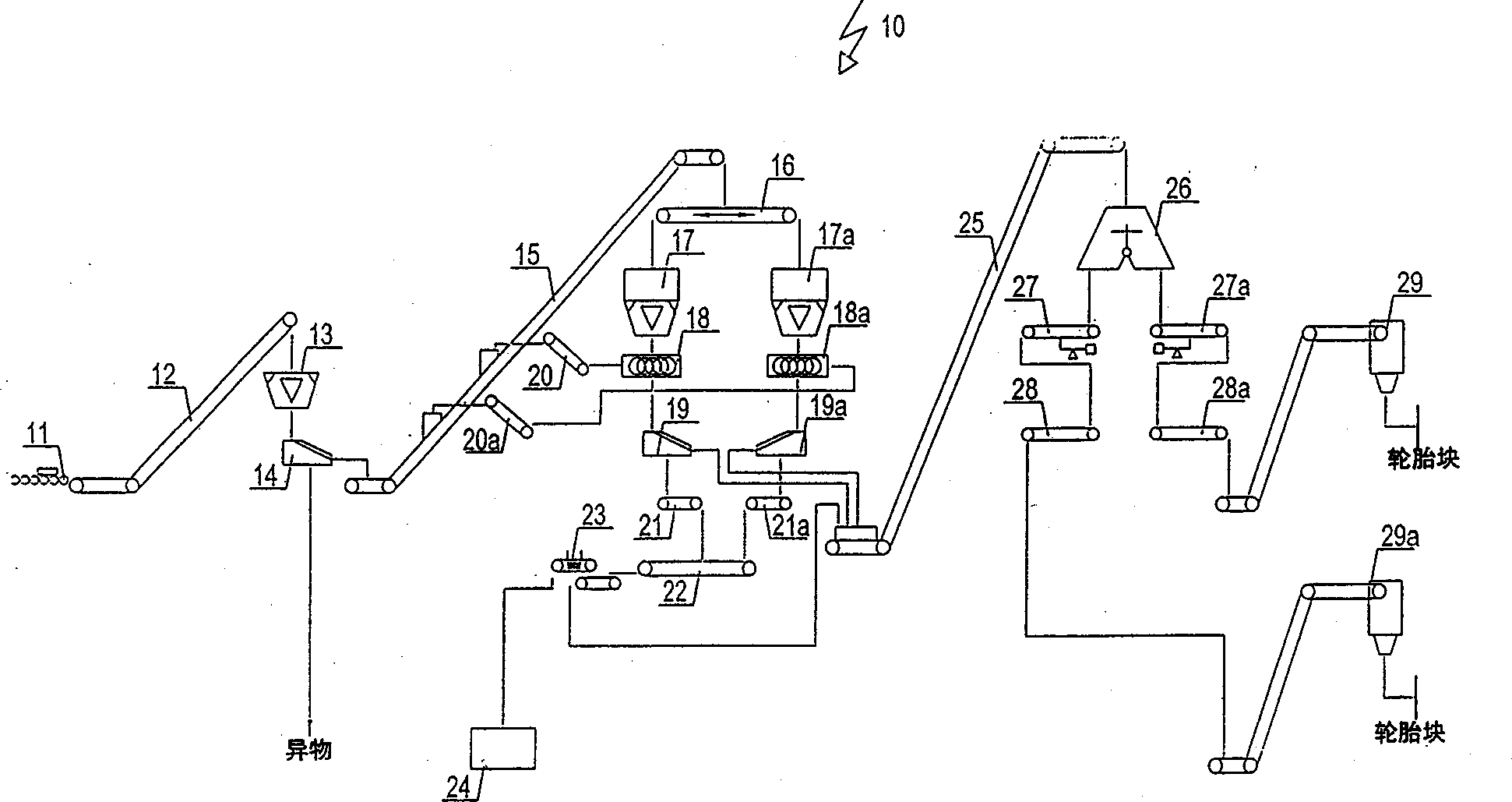

[0030] figure 1 The tire shredding system 10 shown essentially consists of a tire feeding assembly 11 comprising a metering device 11 a and a feeding device 12 . The outlet 1 of the tire feeding assembly 11 is connected with a first crusher 13, which pre-cuts the incoming waste tire raw material to a certain particle size, and after the crusher 13 is a separator 14, which 14 Separation of inorganic components and water.

[0031] A conveying device 15 conveys the coarsely crushed material via a distribution device 16 to the second crushers 17 and 17a. The distributor 16 is bidirectionally rotatable so that the lower two parallel crushers 17 and 17a can be evenly loaded.

[0032] Alternatively, the pre-shredded material loaded onto the conveyor 15 comprises scrap tires or a plastic-metal-fibre mixture.

[0033] The crushers 17, 17a are followed by sorting units 18 and 18a and the sorted material is fed to separators 19 and 19a which separate exposed steel, fibrous reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com