Hydraulic oil soot exhauster with frequency-varying displacement-type speed control

A technology of volumetric speed regulation and oil pumping unit, which is applied in the direction of transmission control, mechanical equipment, and components with teeth, etc. It can solve the problem of not fully utilizing the efficiency of the motor and hydraulic pump, the inability of the motor to automatically adjust the output power, and oil pumping. The energy-saving effect of the computer is not obvious, and the software and hardware resources are abundant, the energy-saving effect is remarkable, and the energy-saving effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

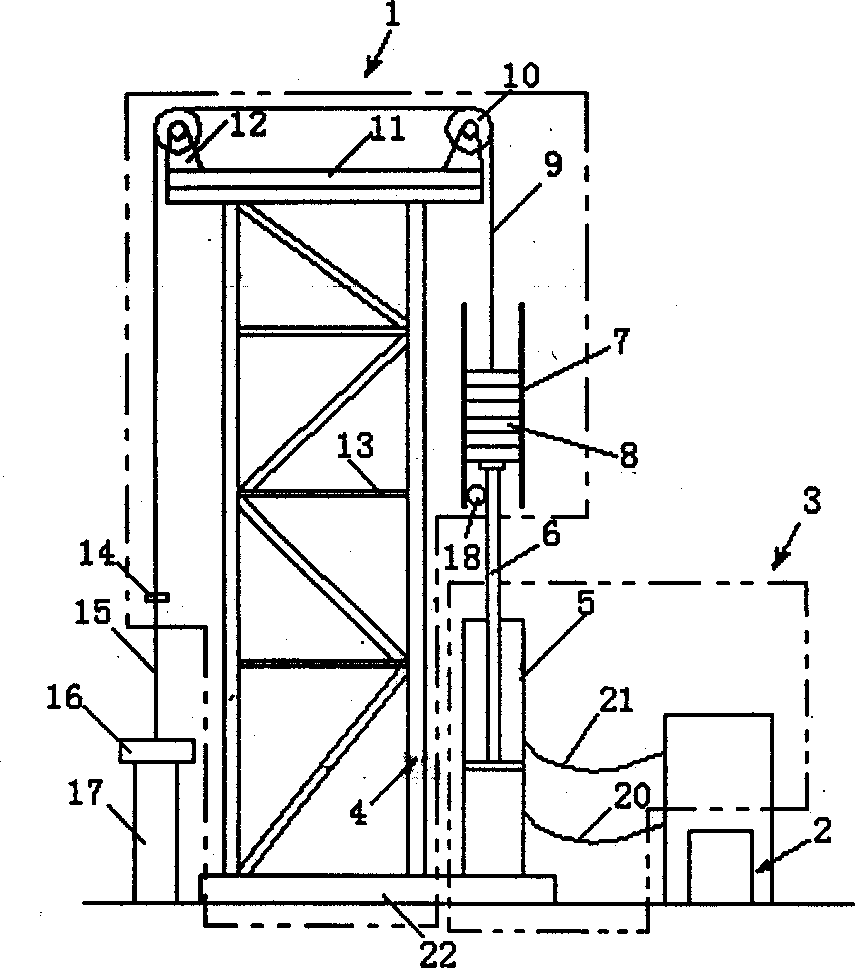

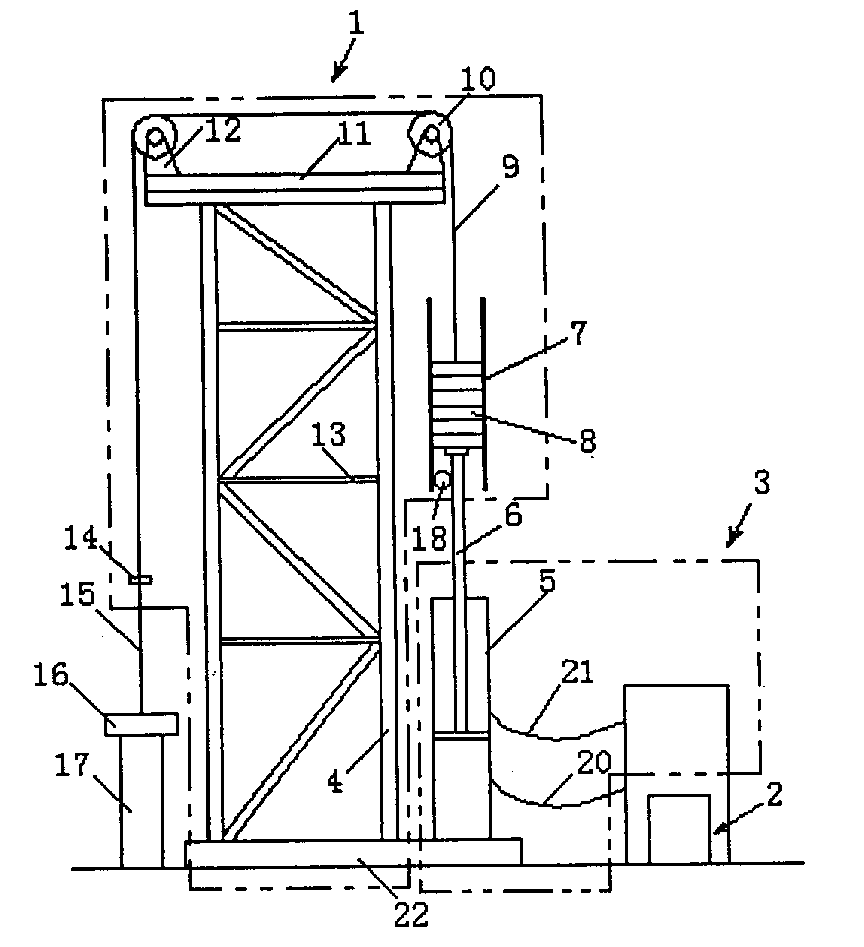

[0029] Such as figure 1 , figure 2 As shown, the hydraulic pumping unit controlled by frequency conversion volume speed regulation includes a mechanical device 1, a detection control device 2, and a hydraulic control device 3, wherein:

[0030] 1) In the mechanical device 1, the polished rod 15 of the pumping unit is directly connected to the piston rod 6 of the hydraulic cylinder 5 through the steel wire rope 9 mounted on the rollers 10 at both ends of the upper base plate 11 and the counterweight 8 mounted in the guide rail 7;

[0031] 2) Detection and control device 2: including a speed measuring photoelectric encoder 26, an AC vector frequency converter 28, a control detection unit 29, and a speed position sensor 18; the AC vector frequency converter 28 is connected to the motor 25 through the speed measuring photoelectric encoder 26, and the AC vector 28 is also connected with the motor 25, and the control detection unit 29 is connected with the AC vector frequency conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com