An electron beam fuse additive manufacturing device and method for realizing the preparation of gradient materials

A gradient material and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of large volume, difficult to guarantee the quality of formed parts, difficult to adapt to heterogeneous laminated metal structures, and embedded special material parts manufacturing needs, etc. To achieve the effect of improving flexibility and variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

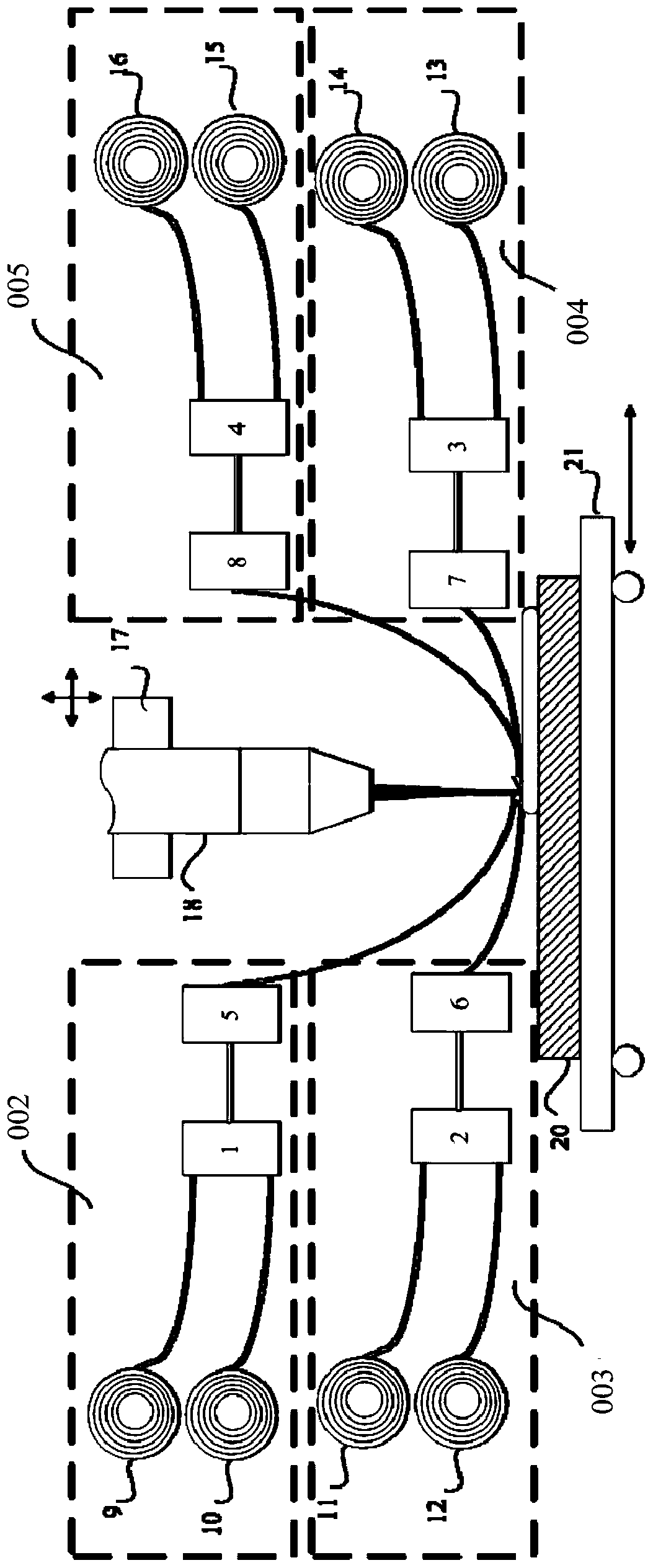

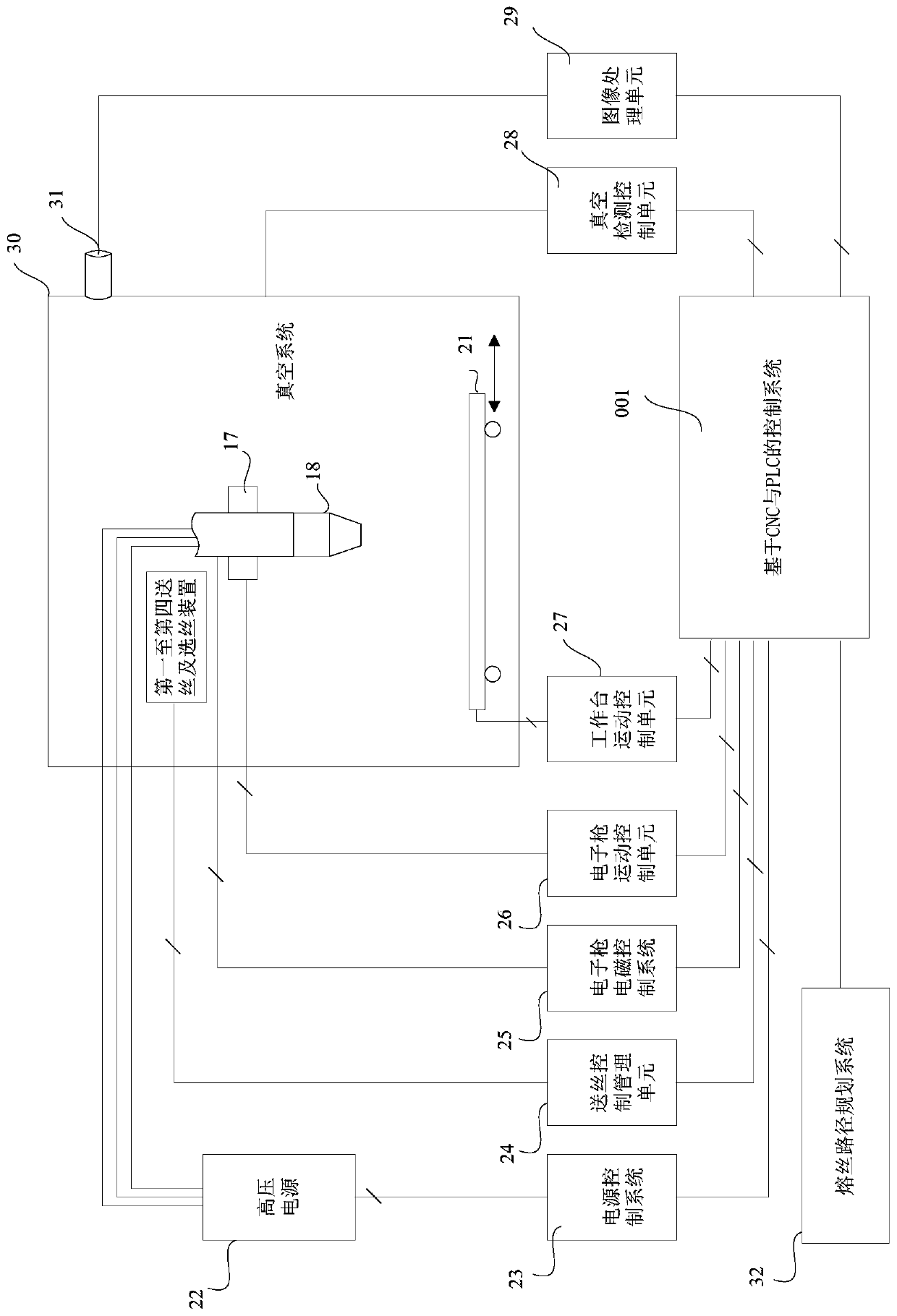

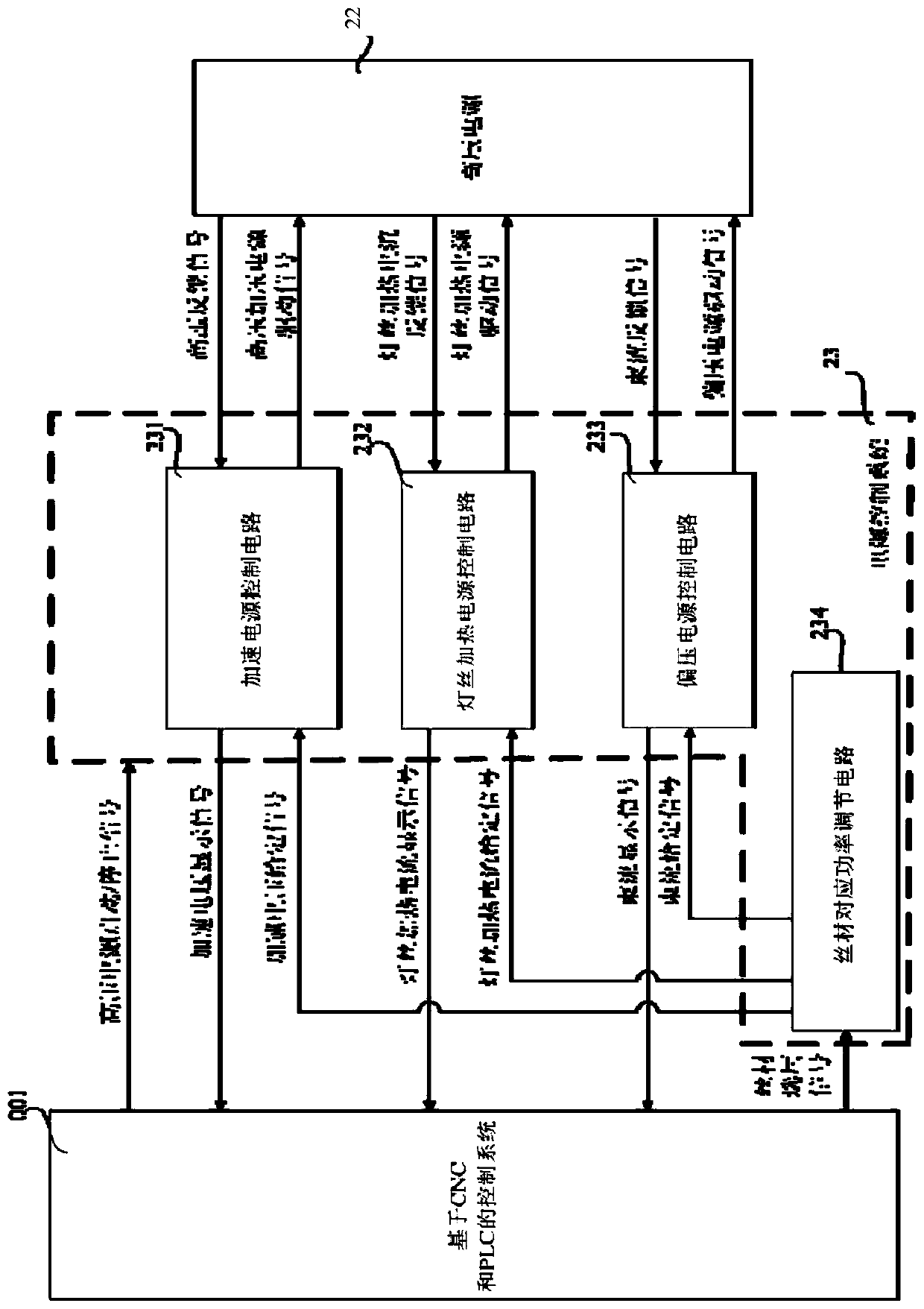

[0077] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Picture 9 , The working process of an electron beam fuse additive manufacturing device and its processing method for the preparation of gradient materials of the present invention will be described. Figure 8 The fuse forming effect shown, and the manufacturing method is as follows:

[0078] The first step is to ensure Figure 8 The power required for each wire shown is stored in the wire-corresponding power adjustment circuit 234, and the focusing current required by each wire is stored in the wire-corresponding focusing current adjustment circuit 254. If it does not exist, go through the series Process test, get Figure 8 The optimal power and focusing current parameters corresponding to one or more of the wires shown are stored in the wire corresponding power adjustment circuit 234 and the wire corresponding focusing current adjustment circuit 254 respectively;

[0079] In the...

Embodiment 2

[0103] Such as Picture 10 As shown, for an electron beam fuse additive manufacturing device that realizes the preparation of gradient materials of the present invention, the following Picture 10 The overall control principle of the fuse forming effect shown is similar to that of Embodiment 1. The main difference is that the path parameters planned by the fuse path planning system are different, and different horizontal rotation motion parameters are required. The key control system work sequence and power supply parameter settings , Wire selection and wire feeding settings are also different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com