Multi-functional cleaning module and cleaning apparatus using the module

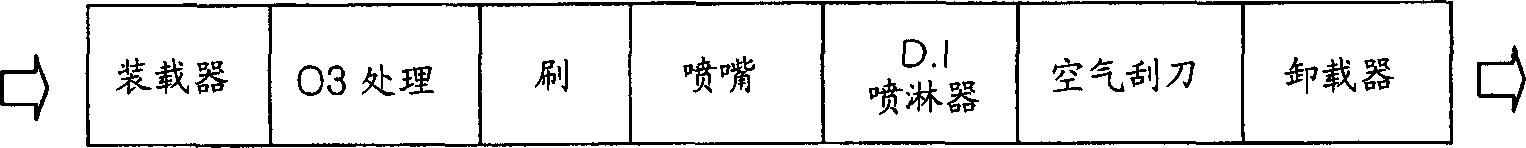

A multi-functional, high-speed technology, applied in cleaning methods using tools, cleaning methods using liquids, lighting and heating equipment, etc., can solve problems such as difficulty in continuous operation, large installation area of cleaning parts, and reduced FAB efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

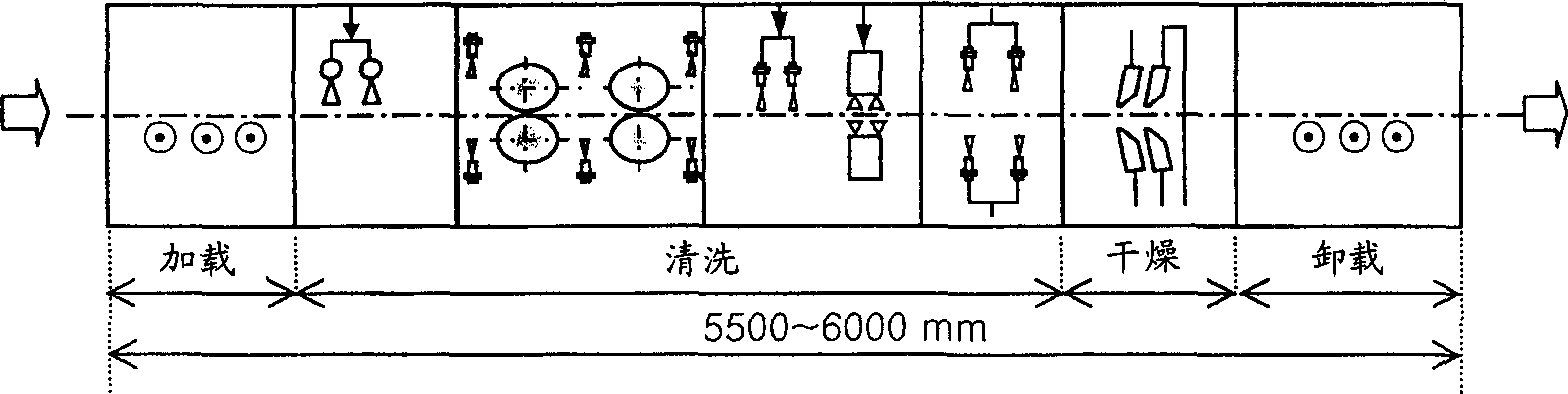

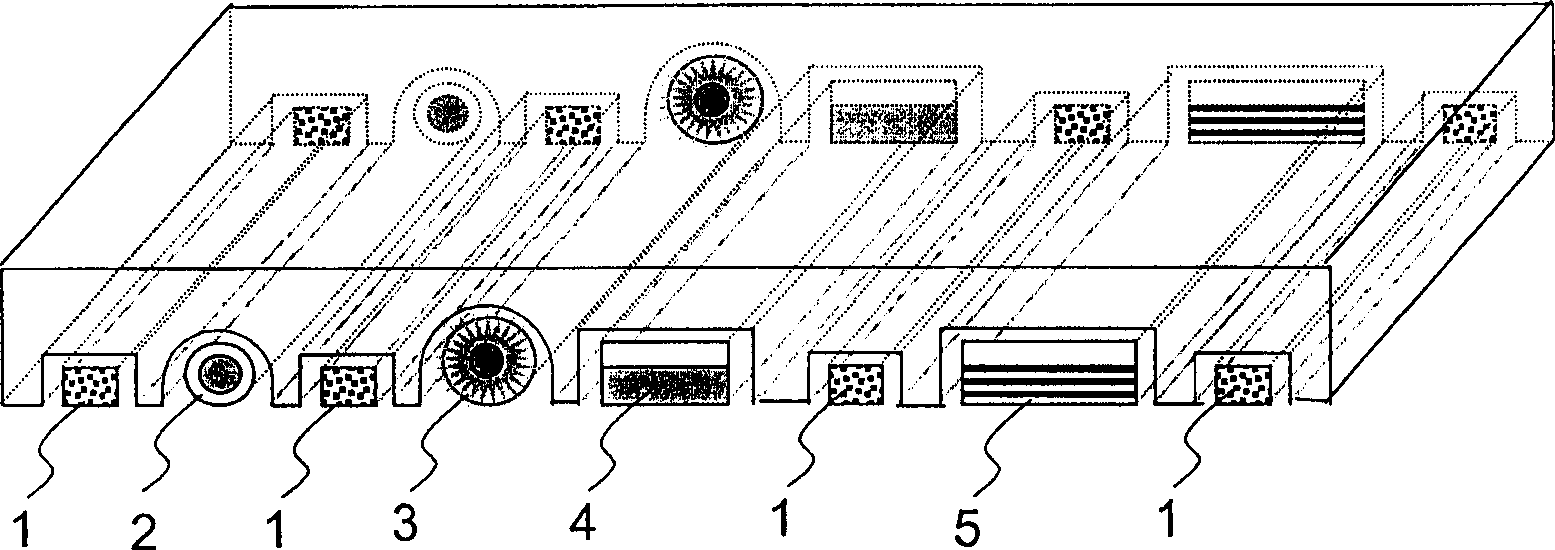

[0031] Hereinafter, the multifunctional cleaning module of the present invention and the cleaning equipment using the module will be described in detail with reference to the accompanying drawings.

[0032] figure 2 is a schematic perspective view showing a multifunctional cleaning module according to the present invention.

[0033] The multifunctional cleaning module according to the present invention includes a plurality of air curtains 1, eximer ultraviolet light irradiation devices 2, brushes 3, high-speed spray devices 4, and air scrapers 5, which are sequentially arranged on a plane, and the glass substrate can be These sections are inserted consecutively.

[0034] A plurality of air curtains 1 are used to isolate possible mutual interference between the above-mentioned components.

[0035] On the other hand, each component of the multifunctional cleaning module of the present invention including the air scraper is improved compared with the conventional cleaning modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com