Method for making composite plate material on porous metal plate

A composite plate and metal plate technology, applied in the field of material processing, can solve the problems of affecting product quality, not very firm bonding, peeling and delamination, etc., to achieve the effect of reducing material cost, low decoration cost and wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

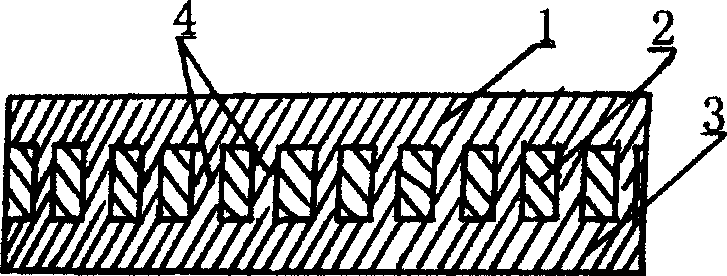

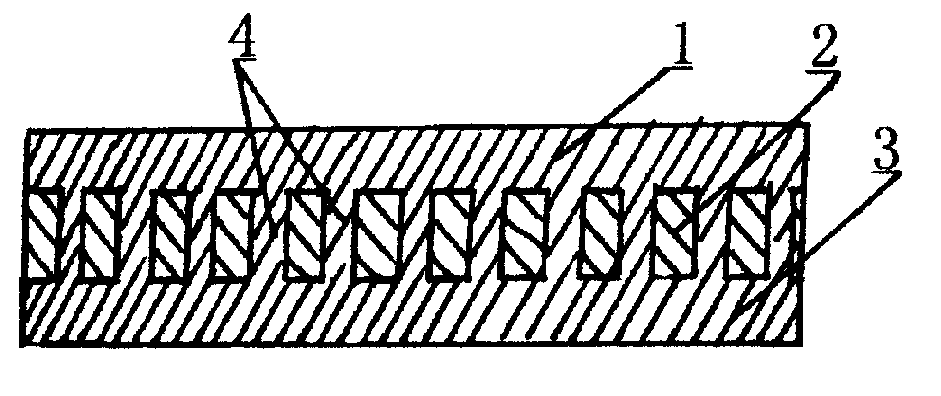

[0010] figure 1 Shown is a schematic diagram of the structure of the composite plate of the present invention. The present embodiment takes the iron core plate as an example to illustrate, and the iron core plate 2 is provided with holes 4 with regular or irregular shapes, or made into a mesh, and the arrangement of the holes It can also be regular or irregular. The bottom layer 3 is stacked under the core plate 2 before die-casting. At the same time, it passes through the bottom of the container containing the same liquid material as the bottom layer. When passing through, the upper layer of liquid material flows evenly on the core plate 2. The upper surface and the hole 4, the liquid material in the hole 4 and the contact layer of the bottom layer 3 are fused together at high temperature, so that under the high pressure in the next step, the two same materials are die-cast together. Then the core plate 2 is "riveted" between the upper layer 1 and the bottom layer 2, and beco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com