Columnar crystals of 6-hydroxy-Naphthoic acid and process for the production thereof

A technology of columnar crystal and naphthoic acid, which is applied in the field of 6-hydroxy-2-naphthoic acid columnar crystal and its preparation, can solve the problems of poor handling, filling and storage, small apparent specific gravity, low fluidity, etc. Excellent properties, easy filling operation and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

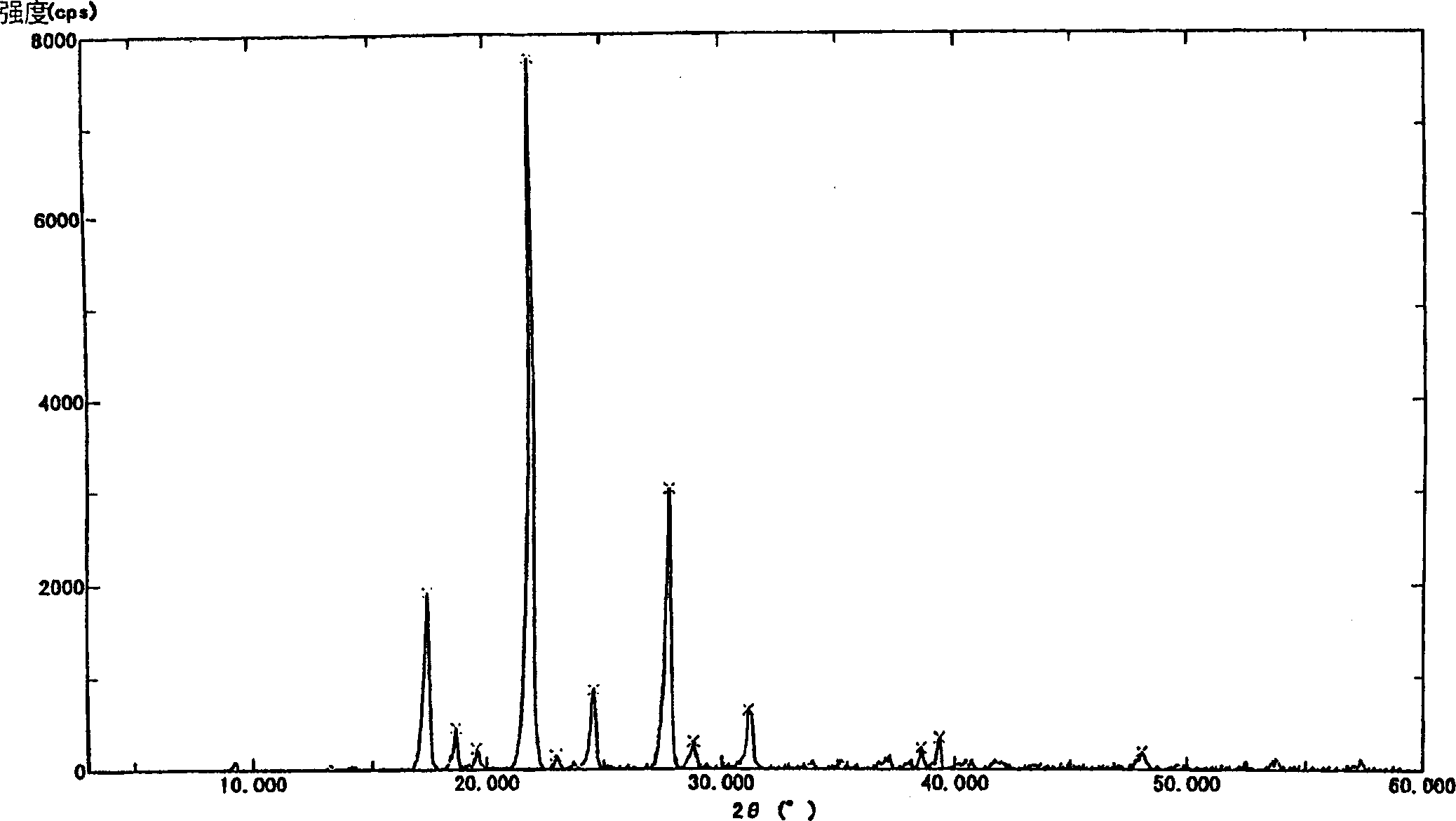

[0049]A 1-liter autoclave was charged with 90 g of 6-hydroxy-2-naphthoic acid and 450 g of water, and the temperature was raised to 150° C. (gauge pressure 0.42 MPa) to obtain a 6-hydroxy-2-naphthoic acid solution. 2.7 g of 3-hydroxy-2,7-naphthoic acid (manufactured by Ueno Pharmaceutical Co., Ltd.) prepared by the Kolber-Schmidt method with a particle size of about 30 μm was added as a crystal nucleus, and cooled at a rate of 0.5°C / min. To 80°C, aging at this temperature for 30 minutes to precipitate crystals. Filtered at the same temperature to obtain 85 g of columnar crystals. The X-ray diffraction results of the columnar crystals obtained are as follows figure 1 As shown, the representative X-ray diffraction angle 2θ is shown in Table 1, the composition is shown in Table 2, the particle size distribution is shown in Table 3, and the values of various physical properties are shown in Table 4.

[0050] The X-ray measurement was performed under the following conditions.

[005...

Embodiment 2

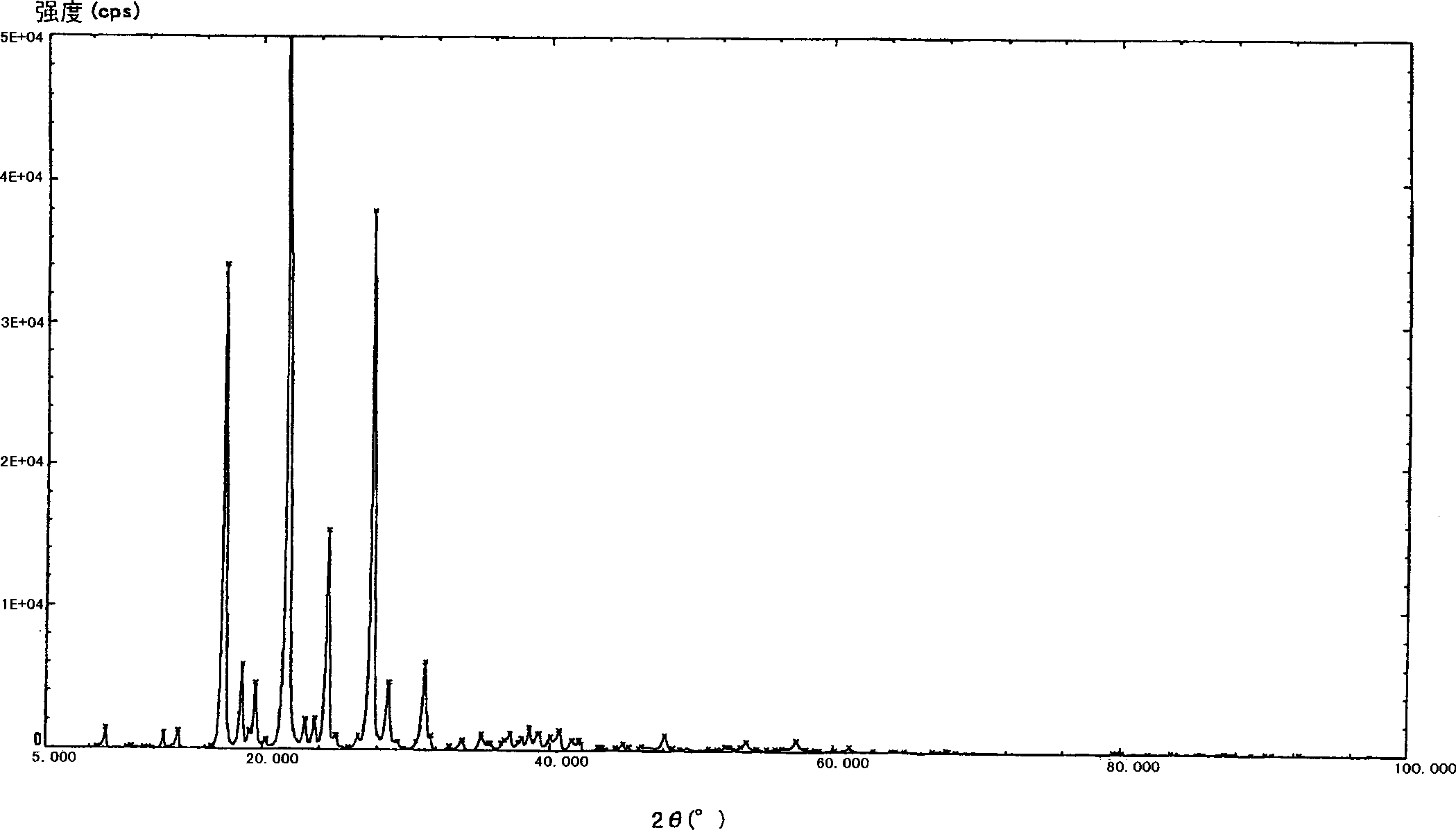

[0063] A 1-liter autoclave was charged with 100 g of crude 6-hydroxy-2-naphthoic acid (manufactured by Ueno Pharmaceutical Co., Ltd.) prepared by the Kolber-Schmidt method, and 650 g of water, and the temperature was raised to 150°C (gauge pressure 0.42 MPa) to obtain a 6-hydroxy-2-naphthoic acid solution. 1 g of 6-hydroxy-2-naphthoic acid columnar crystals with a particle size of about 100 μm prepared in Example 1 were added as crystal nuclei, cooled to 80°C at a rate of 0.5°C / min, and aged at this temperature for 30 minutes. Crystals precipitated. Filter at the same temperature to obtain 90 g of columnar crystals. The X-ray diffraction results of the columnar crystals obtained are as follows figure 2 As shown, the representative X-ray diffraction angle 2θ is shown in Table 1, the composition is shown in Table 2, the particle size distribution is shown in Table 3, and the values of various physical properties are shown in Table 4.

[0064] Among them, the composition of the cr...

Embodiment 3

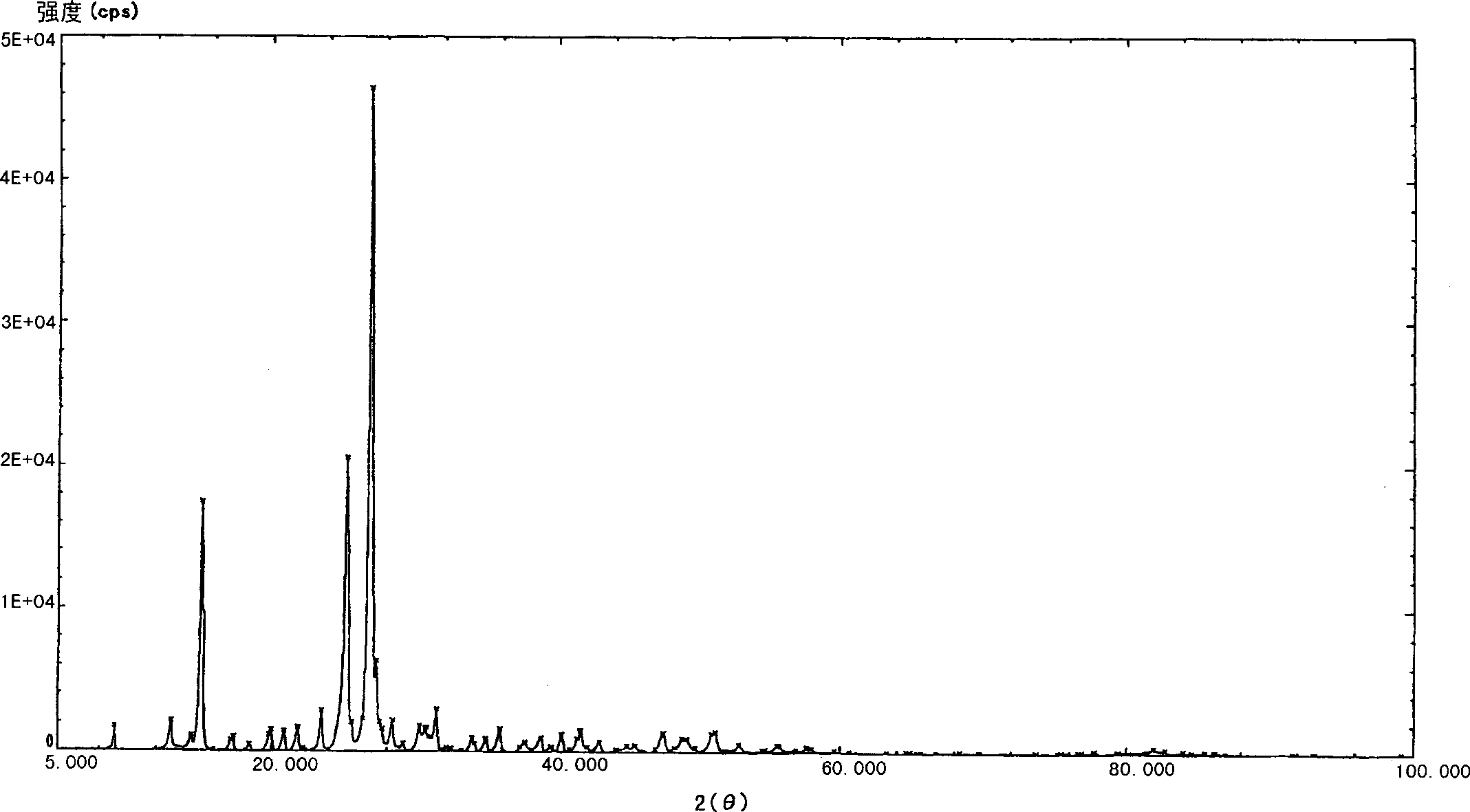

[0071] Except that 100 g of the scaly crystals obtained in Comparative Example 1 was used as a raw material, 90 g of columnar crystals were obtained in the same manner as in Example 2. The X-ray diffraction measurement results of the obtained columnar crystals are as follows Figure 4 As shown, the representative X-ray diffraction angle 2θ is shown in Table 1, the composition is shown in Table 2, the particle size distribution is shown in Table 3, and the values of various physical properties are shown in Table 4. Comparative example 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| liquidity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com