Column supported underground continuous wall

An underground diaphragm wall and basement technology, applied in underwater structures, water conservancy projects, artificial islands, etc., can solve the problems that affect the development of reverse technology, increase the project cost, and increase the cost of entering the rock, etc., to achieve expansion Effectively use the area, save the enclosure wall, and reduce the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

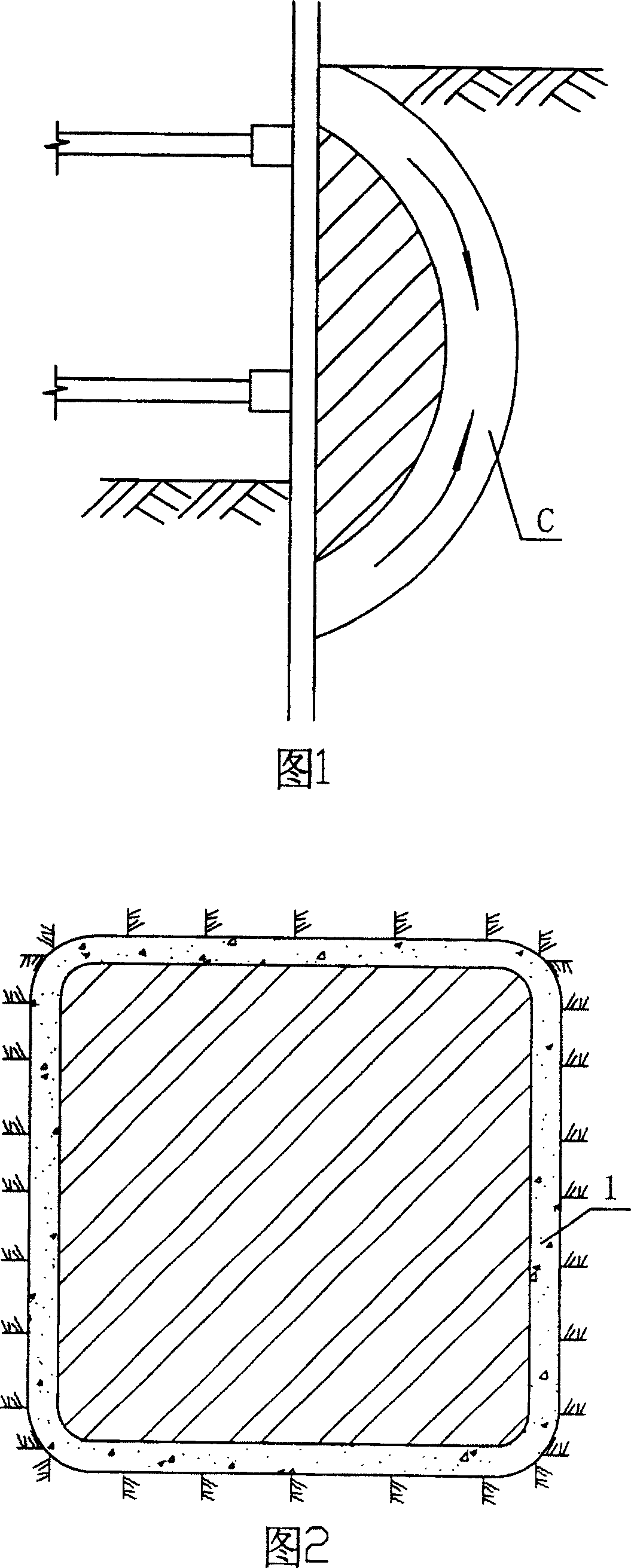

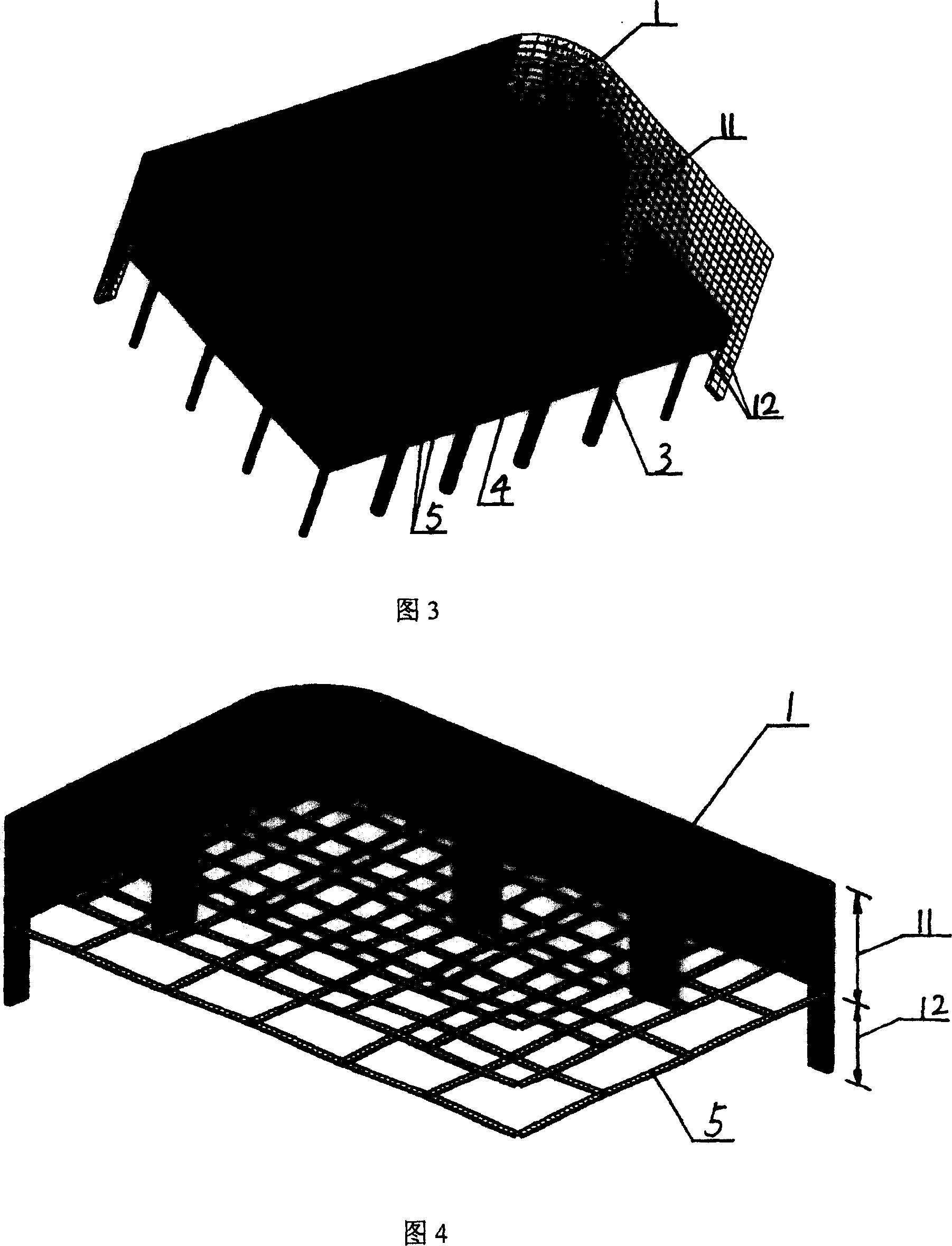

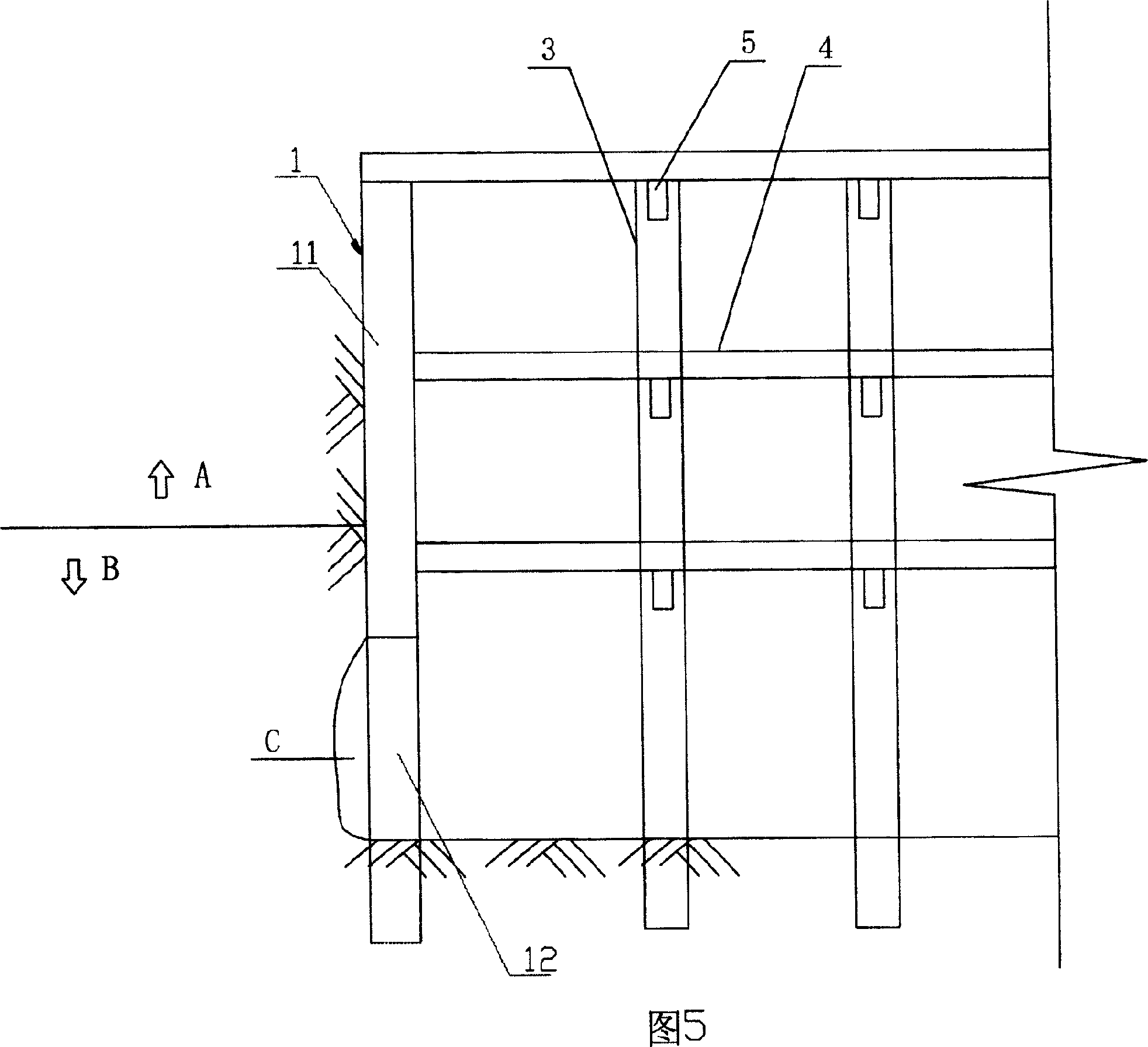

[0039] As shown in Figures 2 to 5, a column-supported underground diaphragm wall constructed by the reverse method of the basement is one of the embodiments of the present invention. The wall body 11 and the deep wall body 12 are formed. The shallow wall body 11 is located on the upper part of the underground diaphragm wall 1 and has a common underground diaphragm wall body structure. A closed wall body is formed along the periphery of the basement, covering all the bad soil A, It is used for soil retaining, water retaining and impermeability during basement reverse construction. The basement superstructure formed by the combination of the shallow wall and the floor 4, beams 5 and columns 3 has huge lateral stiffness, and the lateral earth pressure displacement is small, which can be regarded as a fixed horizontal support for the soil.

[0040] The deep wall body 12 extends from the bottom of the shallow wall body to the rock socket, using the completed basement superstructure...

Embodiment 2

[0042] The column-supported underground diaphragm wall shown in Figures 6 to 10 is the second embodiment of the present invention. The difference from the previous example is that the wall between the two adjacent column-supported walls of the deep wall 12 of the underground continuous wall is different. The spacing is 20 meters, and the shotcrete support composite member 2 is set in this spacing, that is, shotcrete support is used between adjacent column support walls, that is, soil nails 21 are used to fix the metal mesh on the side wall of the foundation pit The concrete is then sprayed to form a thin wall structure with a certain retaining effect. In addition, an anchor rod 22 is also driven into the lower part of the shallow wall to further strengthen the horizontal support of the shallow wall.

[0043] As shown in Figures 6, 8, and 9, the shallow wall of the underground diaphragm wall is formed by constructing the entire underground diaphragm wall into multiple unit widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com