Medium and small sized industrial pulverized-coal fired boiler

A pulverized coal boiler, small and medium-sized technology, applied in the direction of fire tube steam boiler, steam boiler, lump/powder fuel preparation, etc., can solve the problems of complicated equipment, expensive price, complicated technical process, etc., and achieve good ignition performance , Evenly supply pulverized coal and fully burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

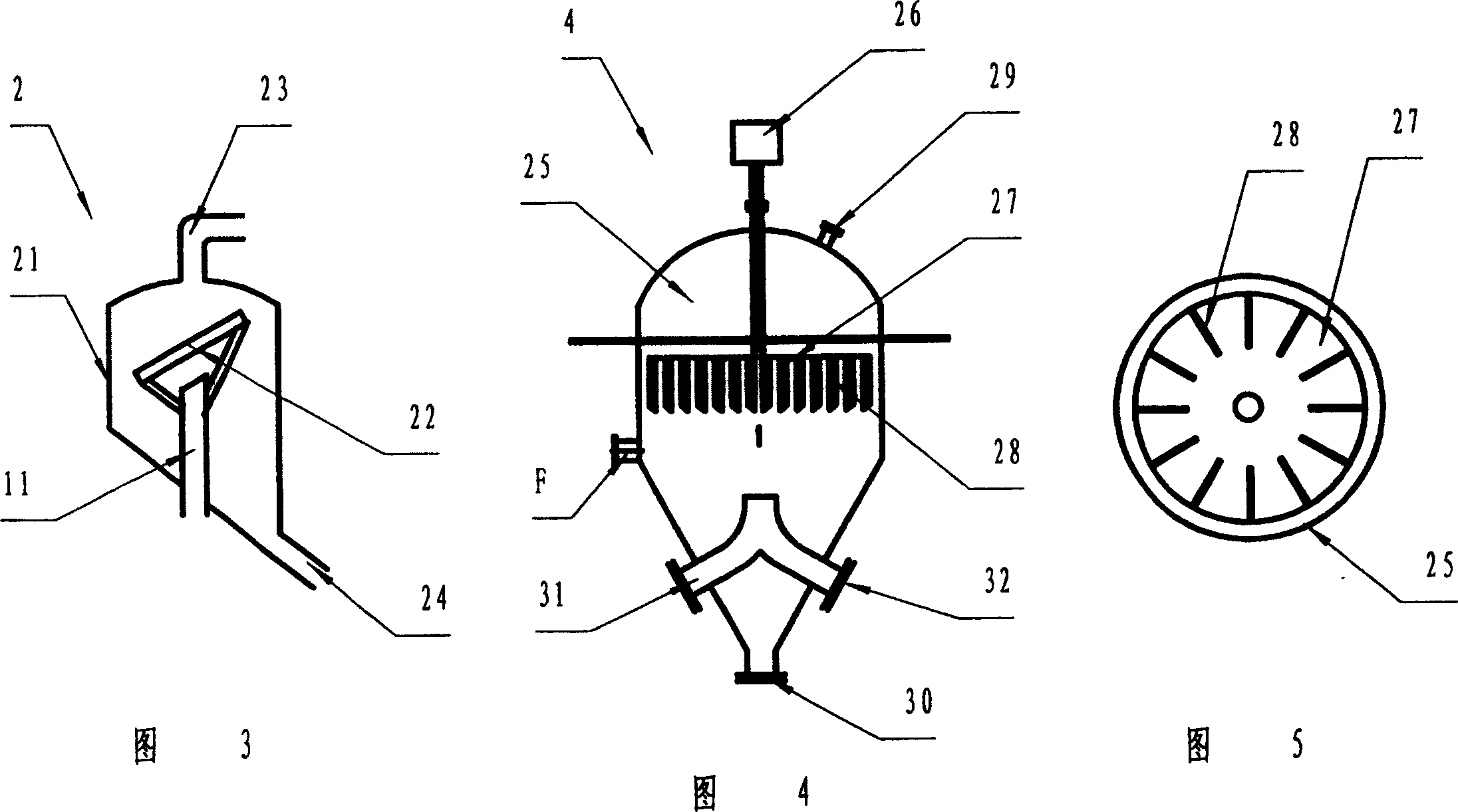

[0024] In order to describe the structure and characteristics of the present invention in detail, the following preferred embodiments are given below and described with accompanying drawings.

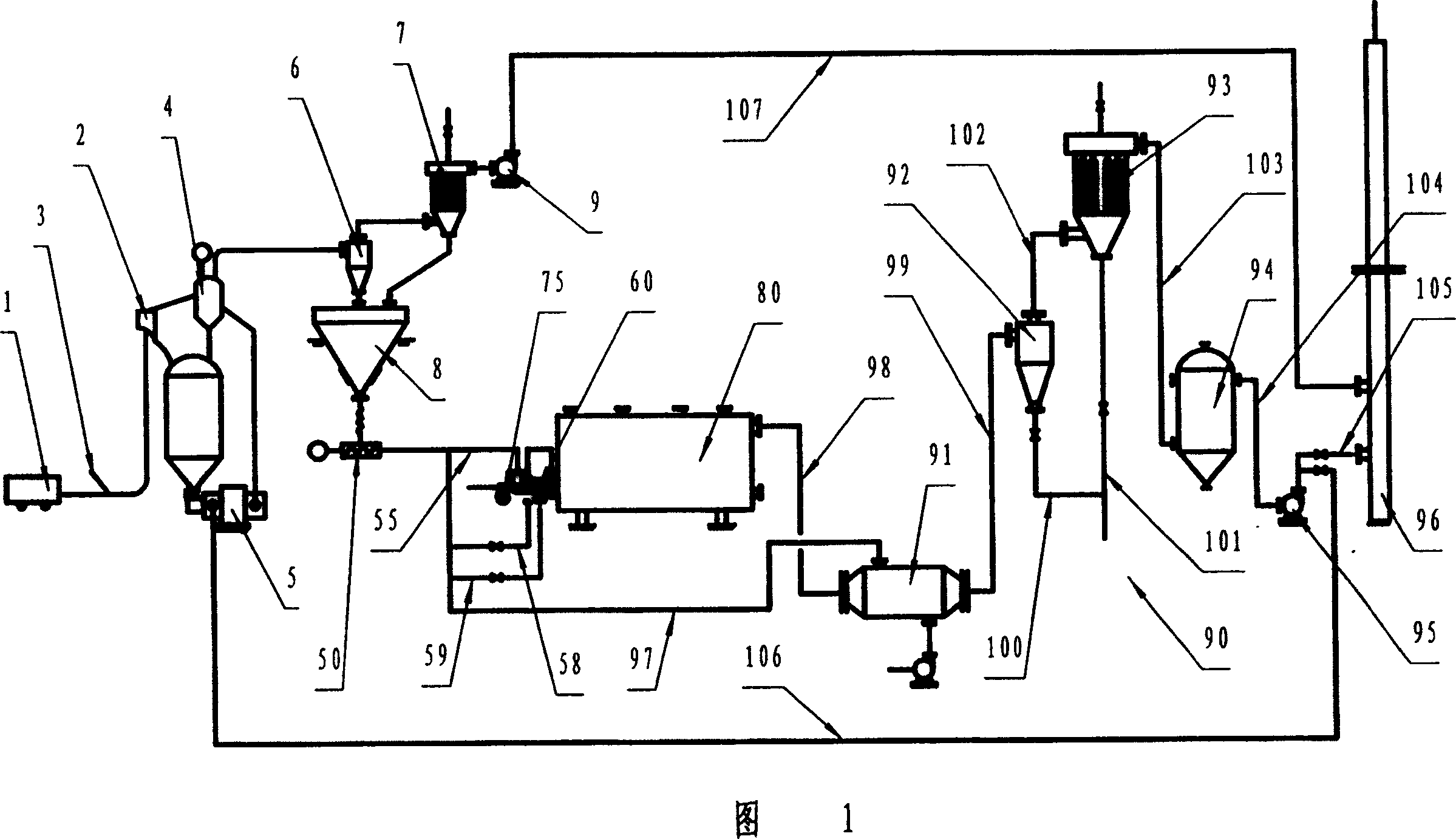

[0025]As shown in Fig. 1, the present invention mainly includes a pre-furnace pulverizing device 10, a uniform pulverized coal supply device 50, a combustion device 60, a boiler body device 80, a dust removal and desulfurization device 90 and an automatic control device.

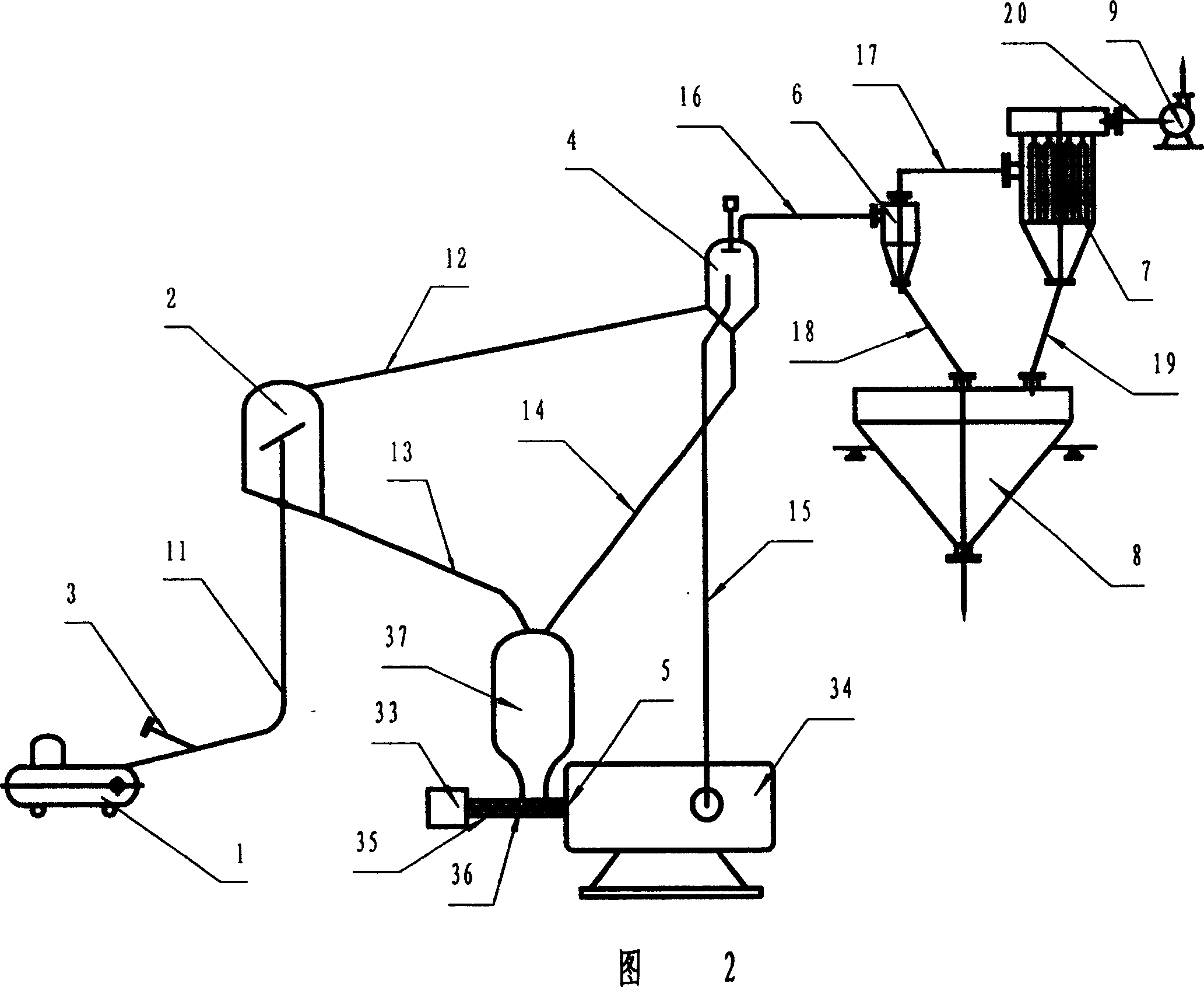

[0026] As shown in Fig. 1 and Fig. 2, the pre-furnace pulverizing device 10 of the present invention includes a high-pressure air pump 1, a baffle separator 2, a coal delivery pipe 3, a pulverized coal separator 4, a coal mill 5, and a cyclone separator 6 , bag filter 7, intermediate silo 8 and exhaust fan 9. The high-pressure air pump 1 is connected to the baffle separator 2 through the delivery pipe 11 , the inlet of the coal inlet pipe 3 is connected to the outdoor coal supply device, and the outlet of the coal inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com