Shunt-feed omnidirectional antenna array

An omnidirectional antenna and array technology, which is applied in the directions of antenna arrays, antenna arrays that are energized separately, antennas, etc., can solve the problems of destroying omnidirectional radiation characteristics of omnidirectional antennas, feeding network shading cannot be eliminated, difficulties, etc., and achieve compact structure , flexible layout, and wide-band characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

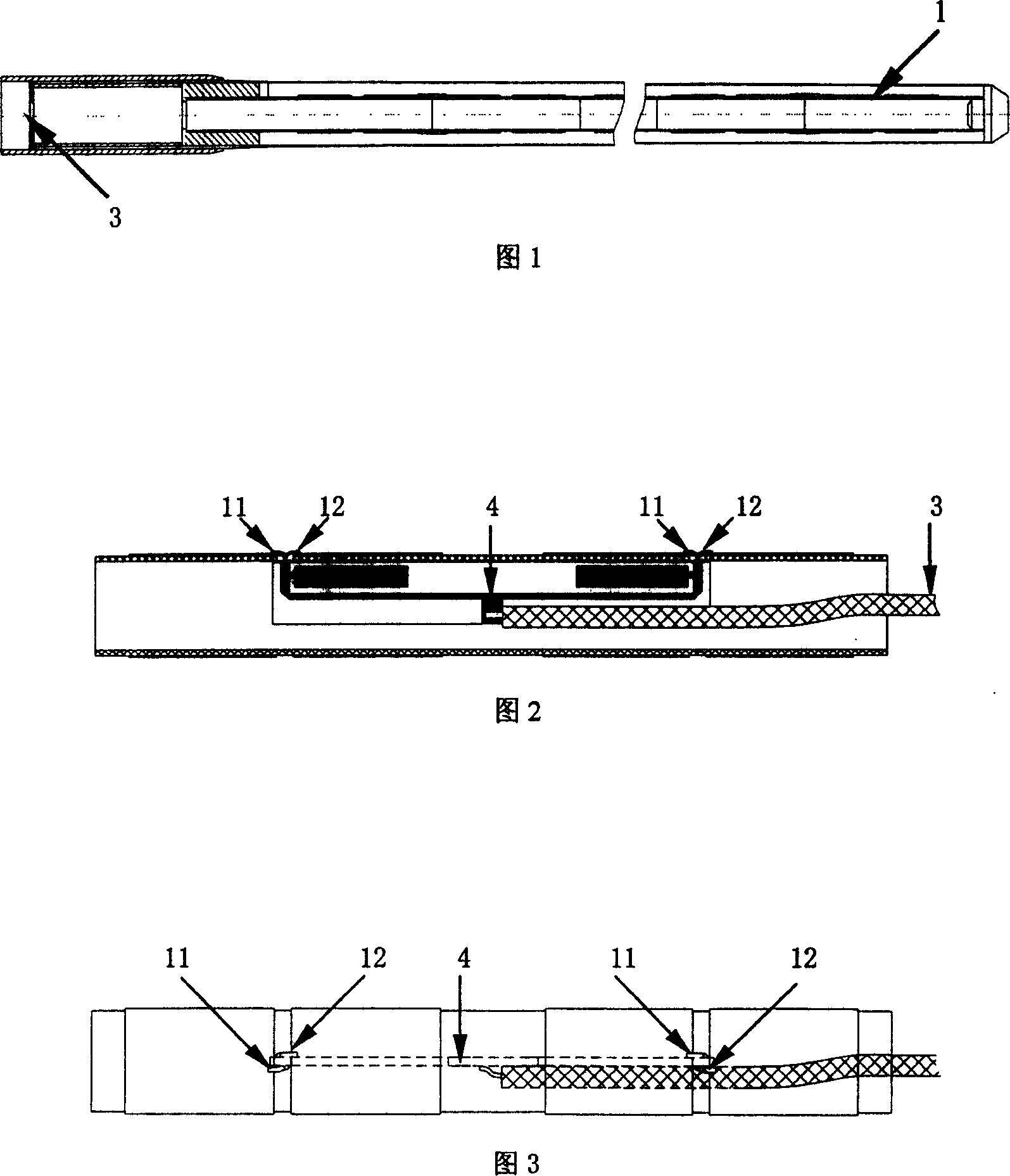

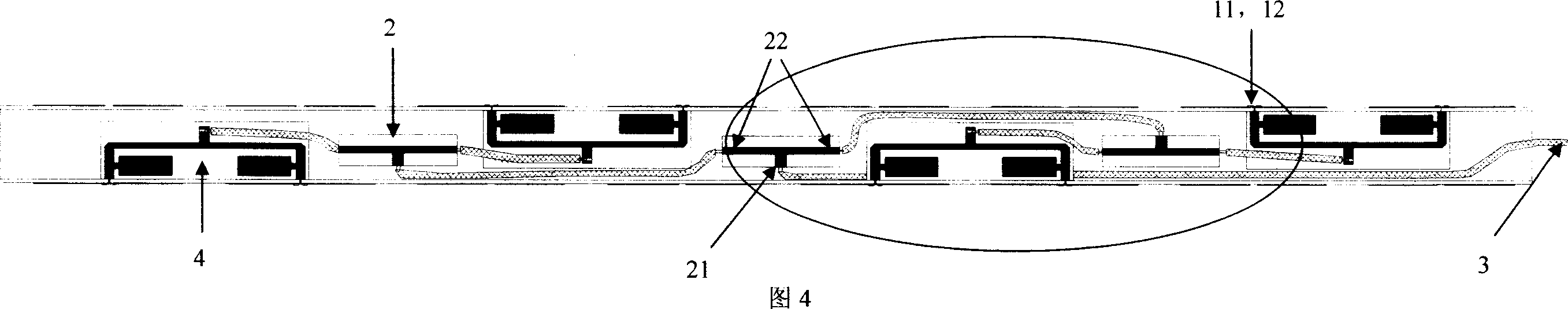

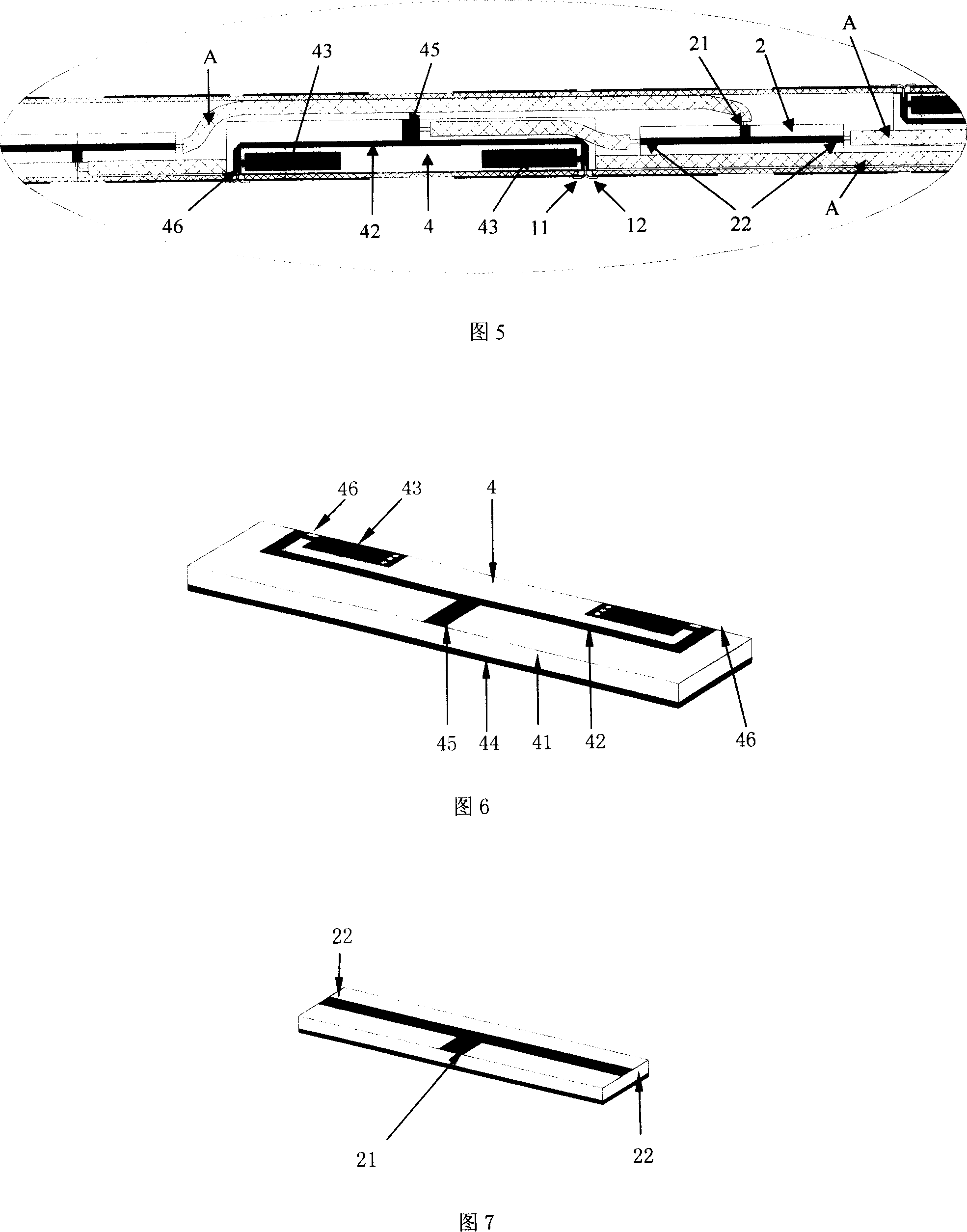

Embodiment 1

[0020] Embodiment 1 A parallel-fed omnidirectional antenna array suitable for broadband work, including at least two hollow elements 1, with an antenna input port 3 at the bottom of the antenna, and a feed circuit 4 inside the hollow elements 1 , the input port 45 of the feed circuit 4 is connected to the antenna input port 3, the feed circuit 4 is composed of a microstrip dielectric substrate 41, a power divider 42, a microstrip short circuit 43 and a microstrip ground plane 44, the microstrip ground plane 44 is located on the surface of the microstrip dielectric substrate 41, the power divider 42 and the microstrip short-circuit line 43 are located on the other surface of the microstrip dielectric substrate 41, the microstrip terminal of the output port 46 of the feed circuit 4 is connected to the microstrip terminal One end of the band short-circuit line 43 is connected, the other end of the microstrip short-circuit line 43 is short-circuited with the microstrip ground plane...

Embodiment 2

[0021] Embodiment 2 A parallel-fed omnidirectional antenna array suitable for broadband operation, including at least two hollow elements 1, with an antenna input port 3 at the bottom of the antenna, and a feed circuit 4 inside the hollow elements 1 , the feed circuit 4 is made up of a microstrip dielectric substrate 41, a power divider 42, a microstrip short circuit 43 and a microstrip ground plane 44, and the microstrip ground plane 44 is arranged on the surface of the microstrip dielectric substrate 41, and the power divider 42 and the microstrip short-circuit 43 are located on the other surface of the microstrip dielectric substrate 41, the microstrip terminal of the output port 46 of the feed circuit 4 is connected with one end of the microstrip short-circuit 43, and the other end of the microstrip short-circuit 43 One end is short-circuited with the microstrip ground plane 44, and a balanced output terminal of the output port 46 of the feed circuit 4 is connected to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com