Electrode for cold cathode discharge tube and electrode assembly for cold cathode discharge tube

A cold cathode and combination technology, which is applied to the main electrode of the discharge tube, the discharge tube, the cold cathode of the discharge tube, etc., can solve the problems of inability to achieve good welding and low metal oxidation temperature, and achieve good processing performance and good resistance to sputtering. Performance, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

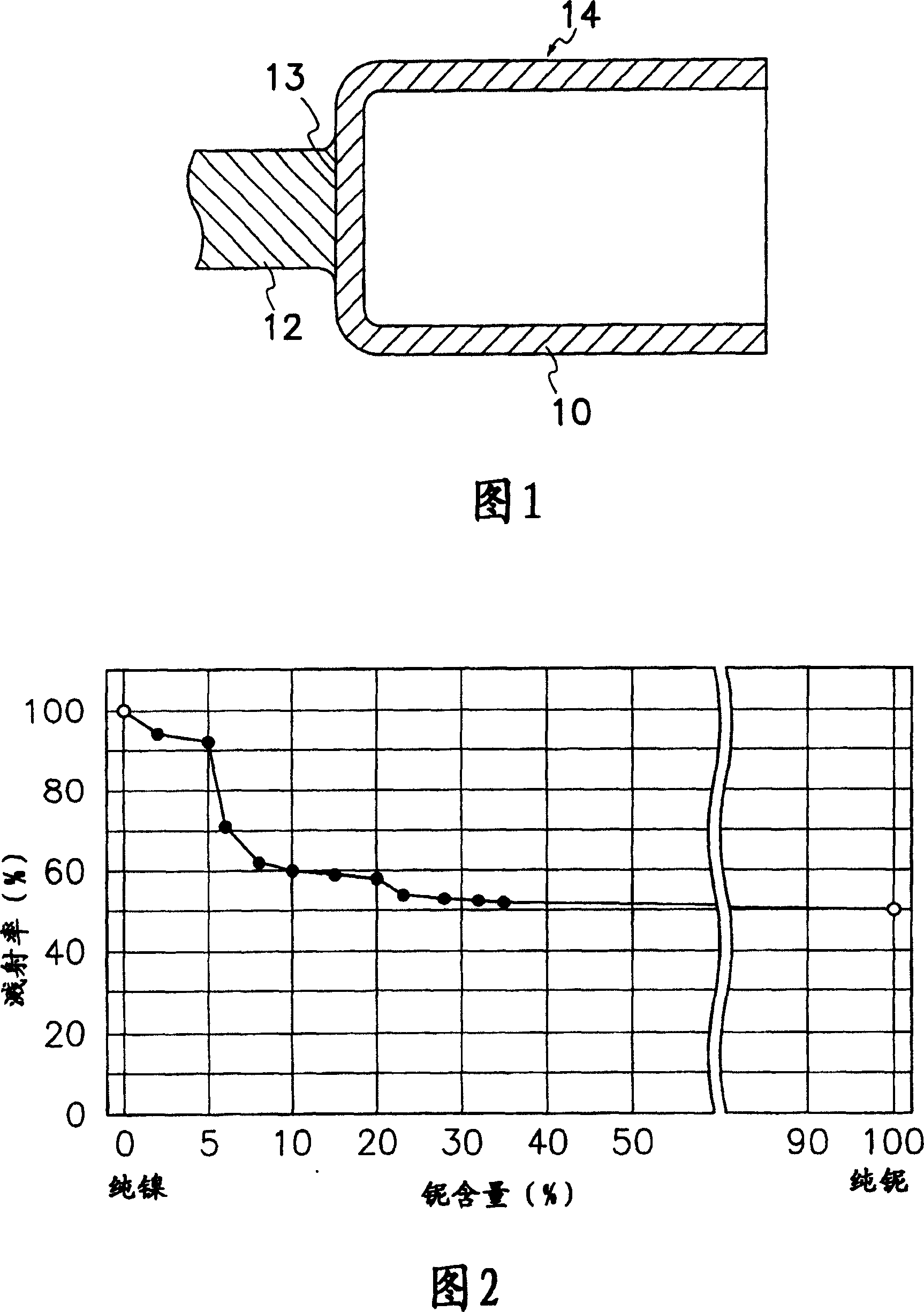

[0015] Embodiments of an electrode for a cold cathode discharge tube and an electrode assembly for a cold cathode discharge tube according to the present invention will be described in detail below with reference to FIGS. 1 and 2 .

[0016] An electrode assembly 14 for a cold cathode discharge tube according to an embodiment of the present invention shown in FIG. 1 includes a cup-shaped electrode 10 made of a nickel-niobium alloy and a lead wire 12 made of tungsten or the like combined with the electrode 10 by an assembly part 13 . The electrode 10 has a shape that closes an opening at one end of a cylindrical body, and a rod-shaped lead wire 12 is welded to the bottom surface of the electrode 10 by laser welding or the like.

[0017] Nickel-niobium alloy test pieces were cut from the forged material with various additions of niobium shown in Table 1 added to nickel, made into a shape of 5×10×10 mm, and each test piece was subjected to a sputtering test. Next, a grinding amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com