Cold cathode fluorescent lamp

A technology for cold cathode fluorescent lamps and phosphor layers, which is applied to discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problem of increasing the number of production steps, complicated adjustment of production steps, and not considering the reduction of sputtering resistance. and other problems, to achieve the effect of excellent long life and excellent sputtering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

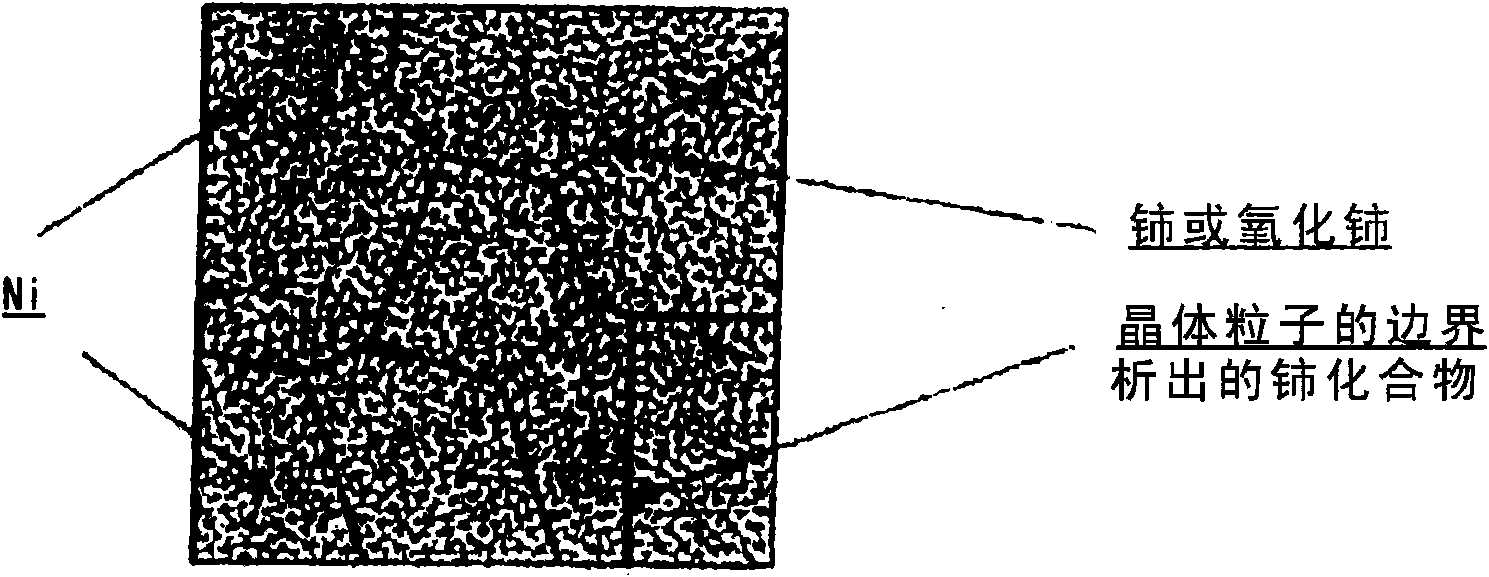

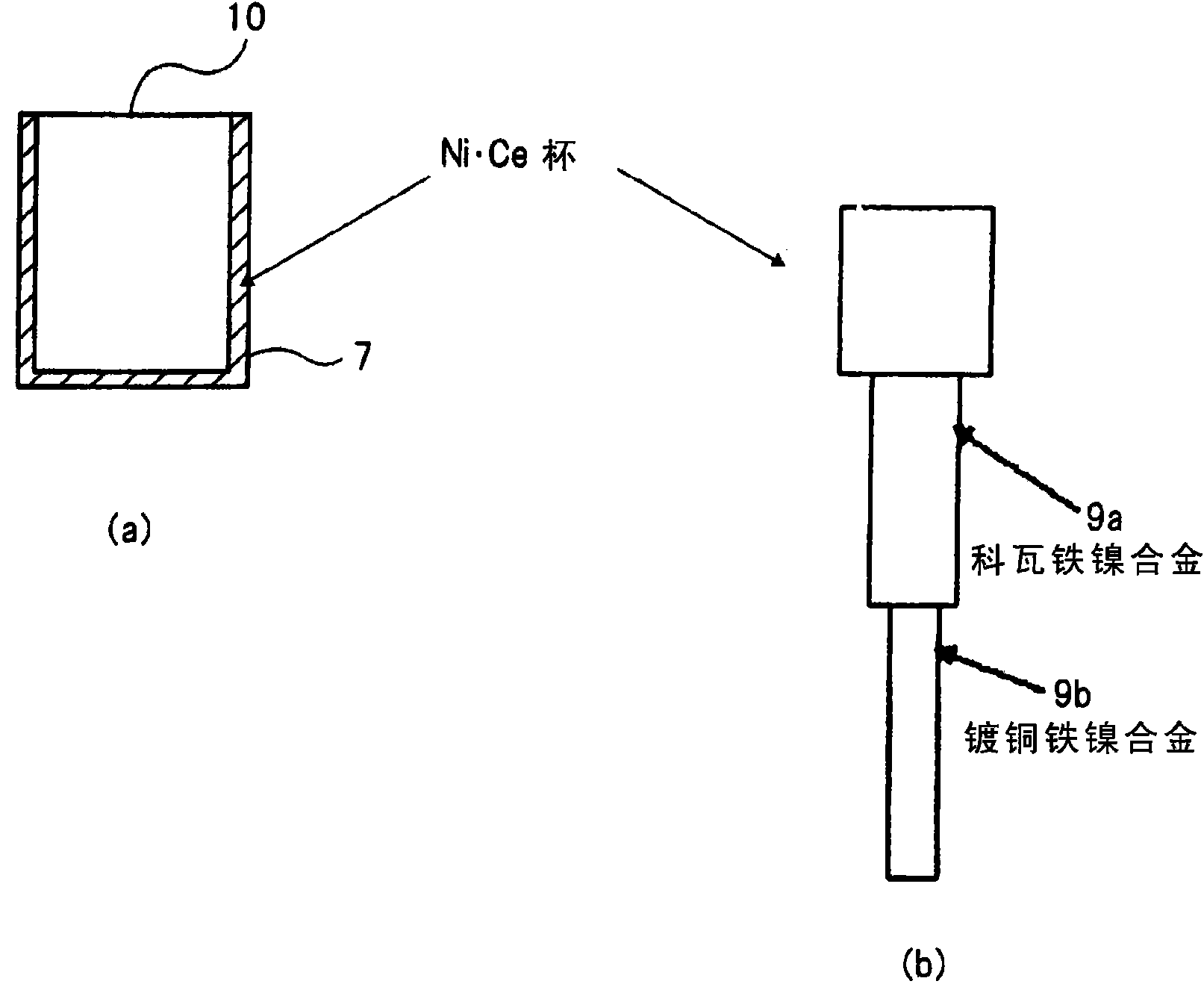

[0053] The starting material (with 0.5% by mass of cerium metal added to nickel) was melted at a temperature equal to or higher than the melting point of nickel. The ingot material was cast in a mold and cooled to room temperature. After that, hot rolling, cold rolling, wire drawing, etc. are repeated to produce a wire material having a diameter of about 0.2 mm. The wire material was subjected to forging processing to produce a cup-shaped electrode having an outer diameter of 1.7 mm and a length of 5 mm. A Kovar wire with a diameter of 0.8 mm was welded to the bottom surface portion of the obtained electrode to be integrated.

[0054] The average diameter of crystal particles of nickel of the electrode was measured by a comparison method. The average diameter of nickel crystal particles was 22 μm.

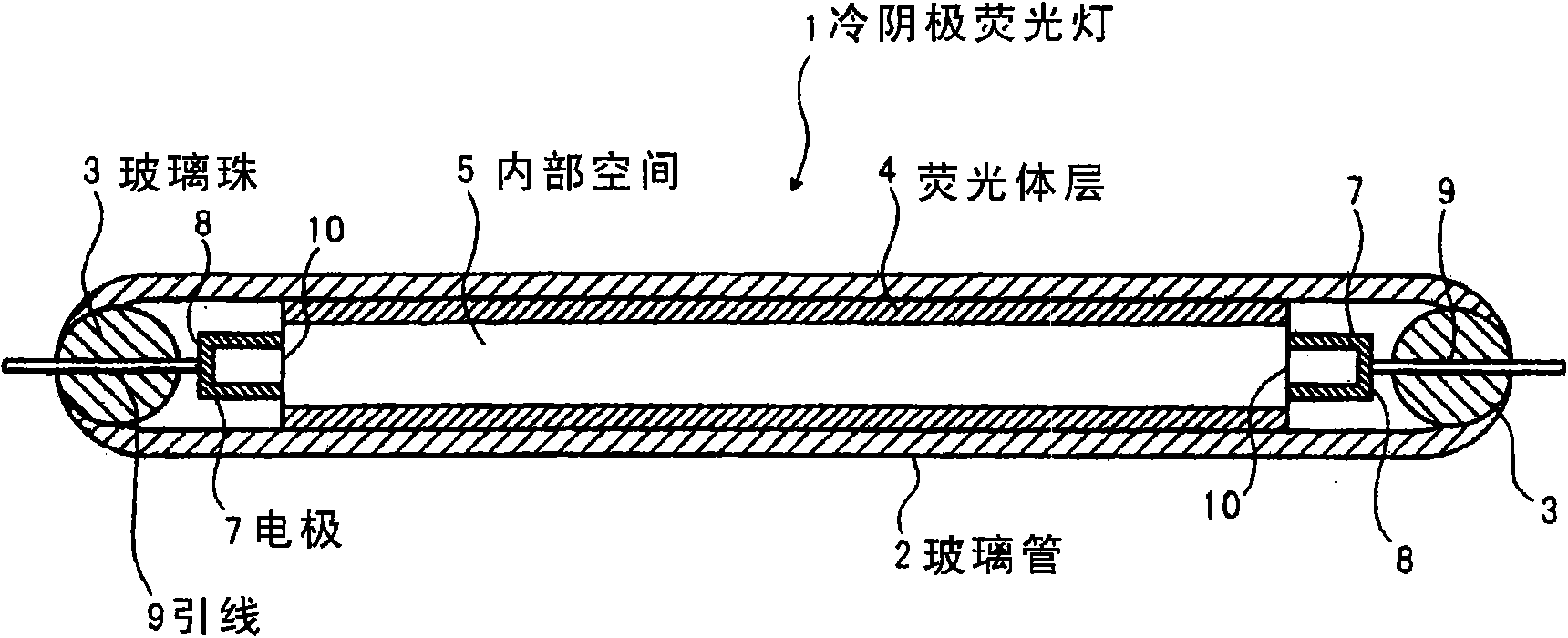

[0055] A phosphor material with a thickness of about 18 μm was coated onto the inner wall surface of a glass tube having an inner diameter of 2.0 mm. Electrodes fused with Kova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com