Deslim-floatation celestite inished ore process

A flotation and desliming technology, used in flotation, solid separation, grain treatment, etc., can solve the problems of low concentrate content, low recovery rate, difficult beneficiation indicators, etc., and achieve low concentrate cost, large processing capacity, Process stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments.

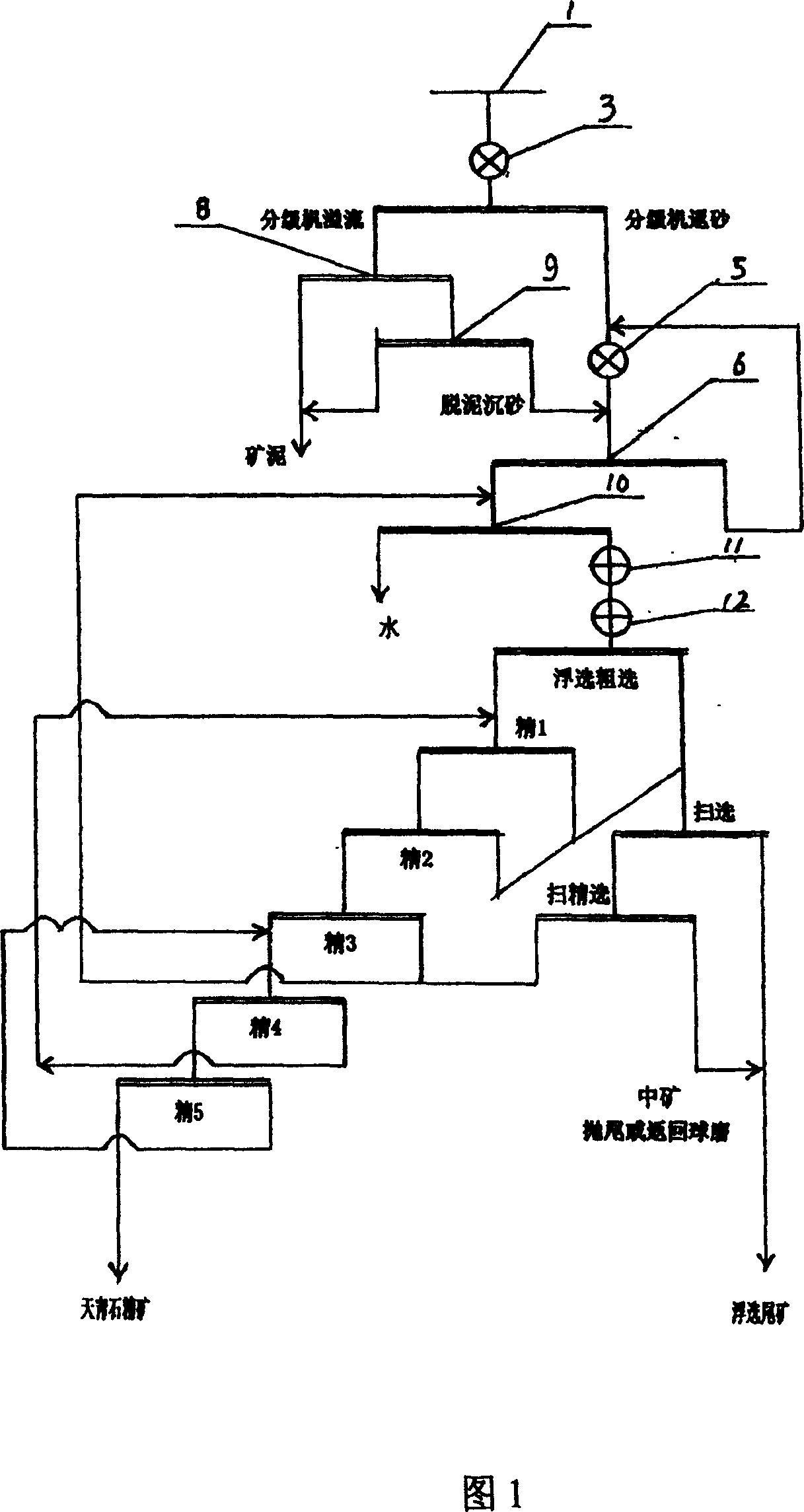

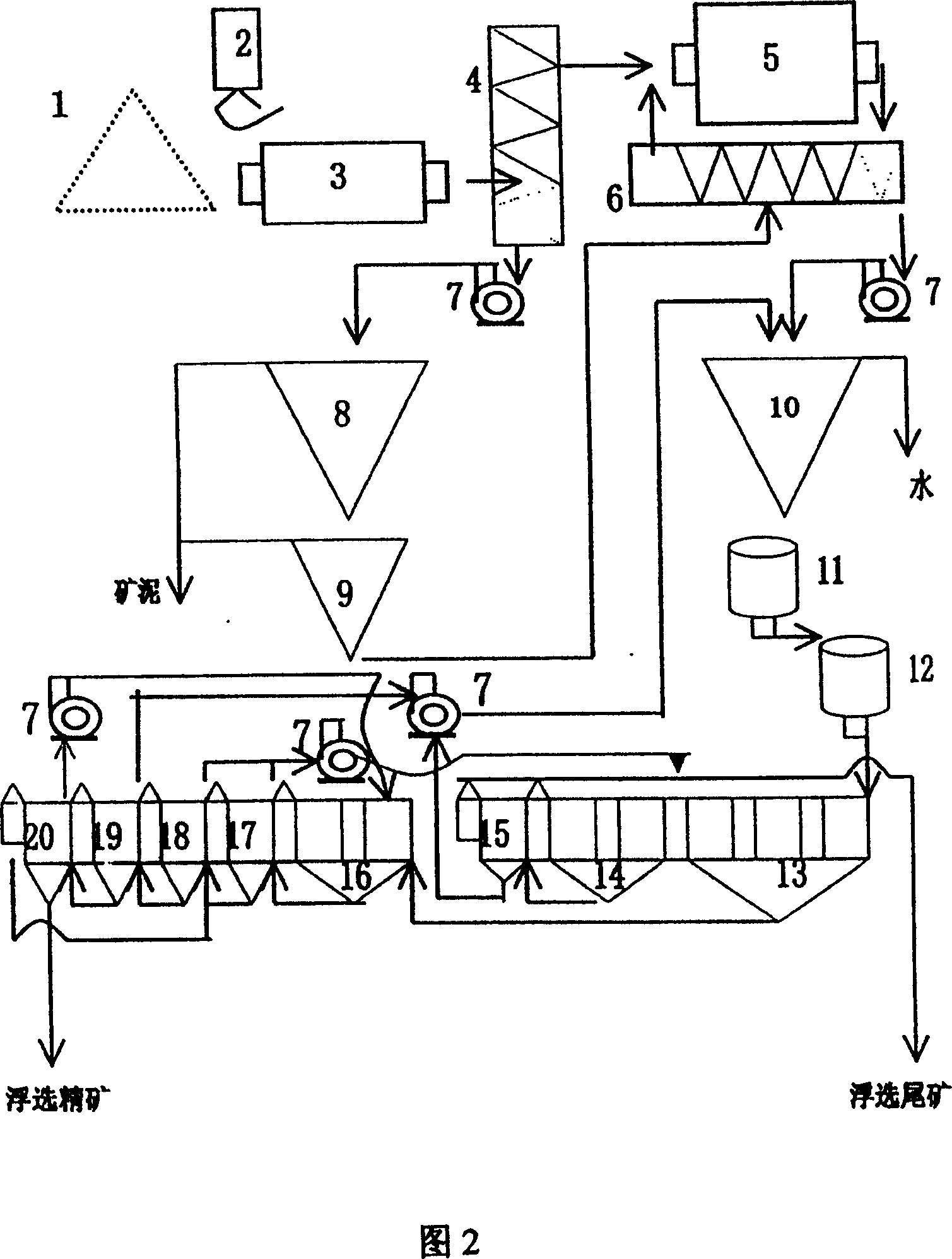

[0025] The process flow of desliming-flotation celestite concentrate in the invention includes a crushing process, a rod grinding process, a flotation process, a concentration process, a first-stage desliming process and a second-stage desliming process; the flotation process includes: a roughing process, a sweeping process Process, sweep selection process, first-level selection process, second-level selection process, third-level selection process, fourth-level selection process, fifth-level selection process;

[0026] Wherein: a) the described rod grinding process is that the particle size is -5mm, SrSO 4 The raw ore with a grade of 44.34% is ground into a desliming particle size of -0.015~-0.020mm;

[0027] b) the described classification overflow process is to use sand pump to send the sand ore to the desliming bucket (8) to carry out the first stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com