Guide boot

A guide shoe and guide rail technology, applied in elevators, transportation and packaging, etc., can solve the problems of large difference, prone to crawling, affecting the comfort of passenger elevators, etc., so as to reduce development and production costs and improve development and production efficiency. , the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

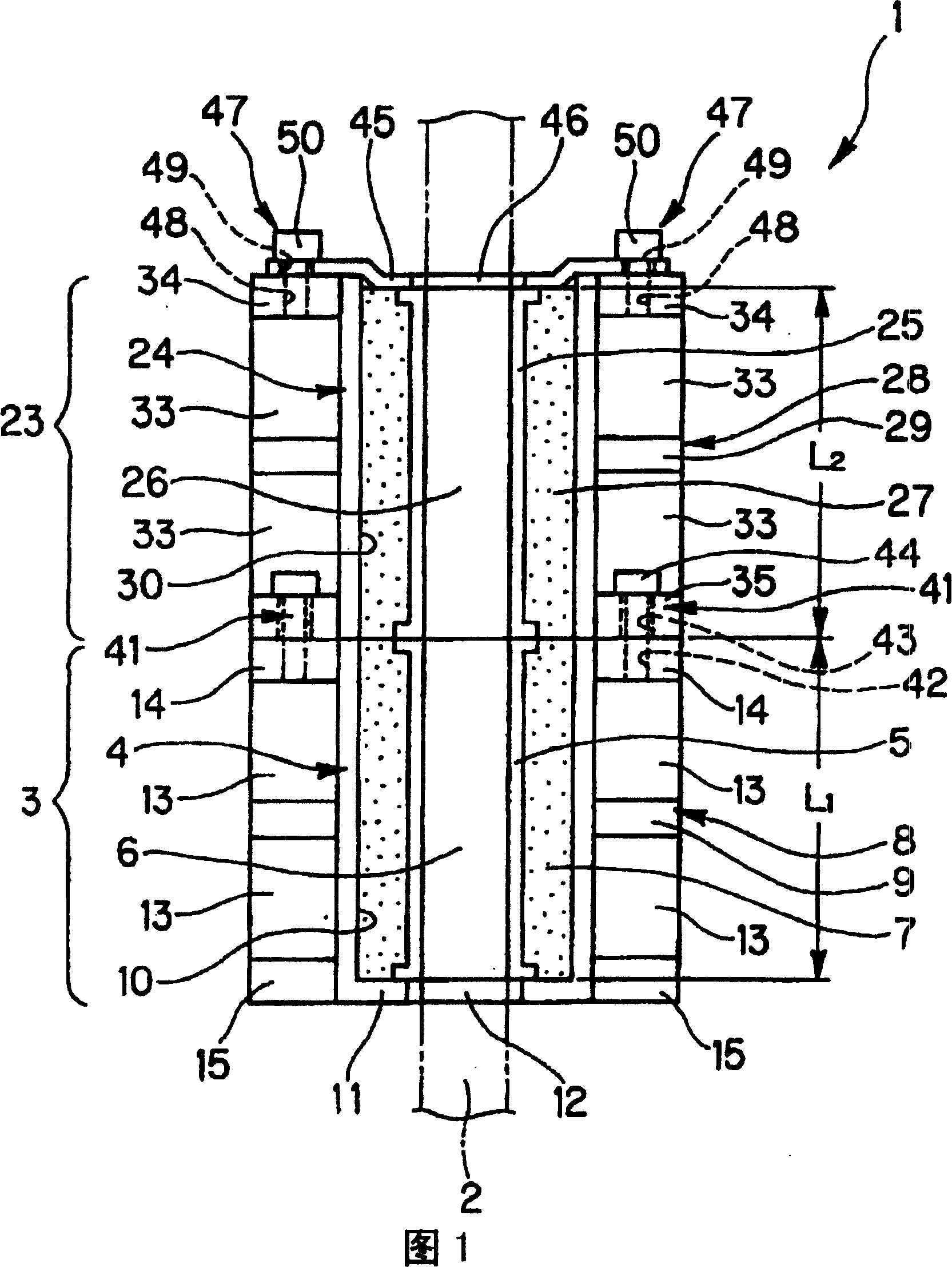

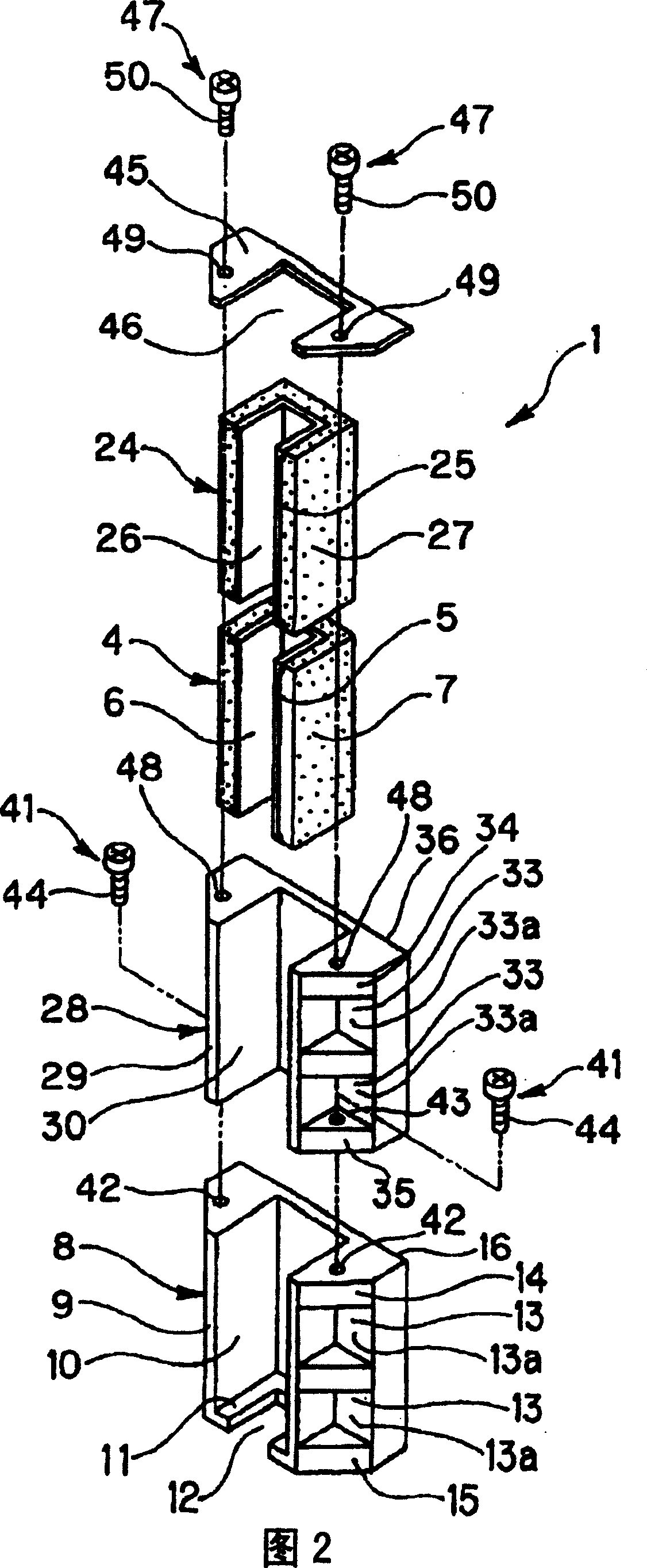

[0015] FIG. 1 is a front view of a guide shoe according to an embodiment of the present invention, and FIG. 2 is an exploded perspective view of FIG. 1 .

[0016] The guide shoe 1 of this embodiment slides on the guide rail 2 arranged in the moving passage to guide the elevator car (not shown) to lift up and down. The guide shoe 1 has a guide shoe assembly 3 with the following structure, a connecting The guide shoe assembly 23 , the connecting means 41 of the two guide shoe assemblies 3 , 23 , the cover 45 and its connecting means 47 . In the guide shoe 1, the guide shoe assembly 23 for connection is connected to the guide shoe assembly 3, and one or more guide shoe assemblies 23 for connection are further connected to the guide shoe assembly 23 for connection ( not shown), and finally cover the cover 45 for fixing.

[0017] The guide shoe assembly 3 adopts the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com