Process for slashing by direct use of starch emulsion

A warp sizing and starch milk technology, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, textiles and papermaking, etc., can solve the problems of low sizing efficiency, surprising amount of steam usage, low sizing efficiency, etc. , to achieve the effect of reduced steam consumption, small moisture regain, and reduced drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

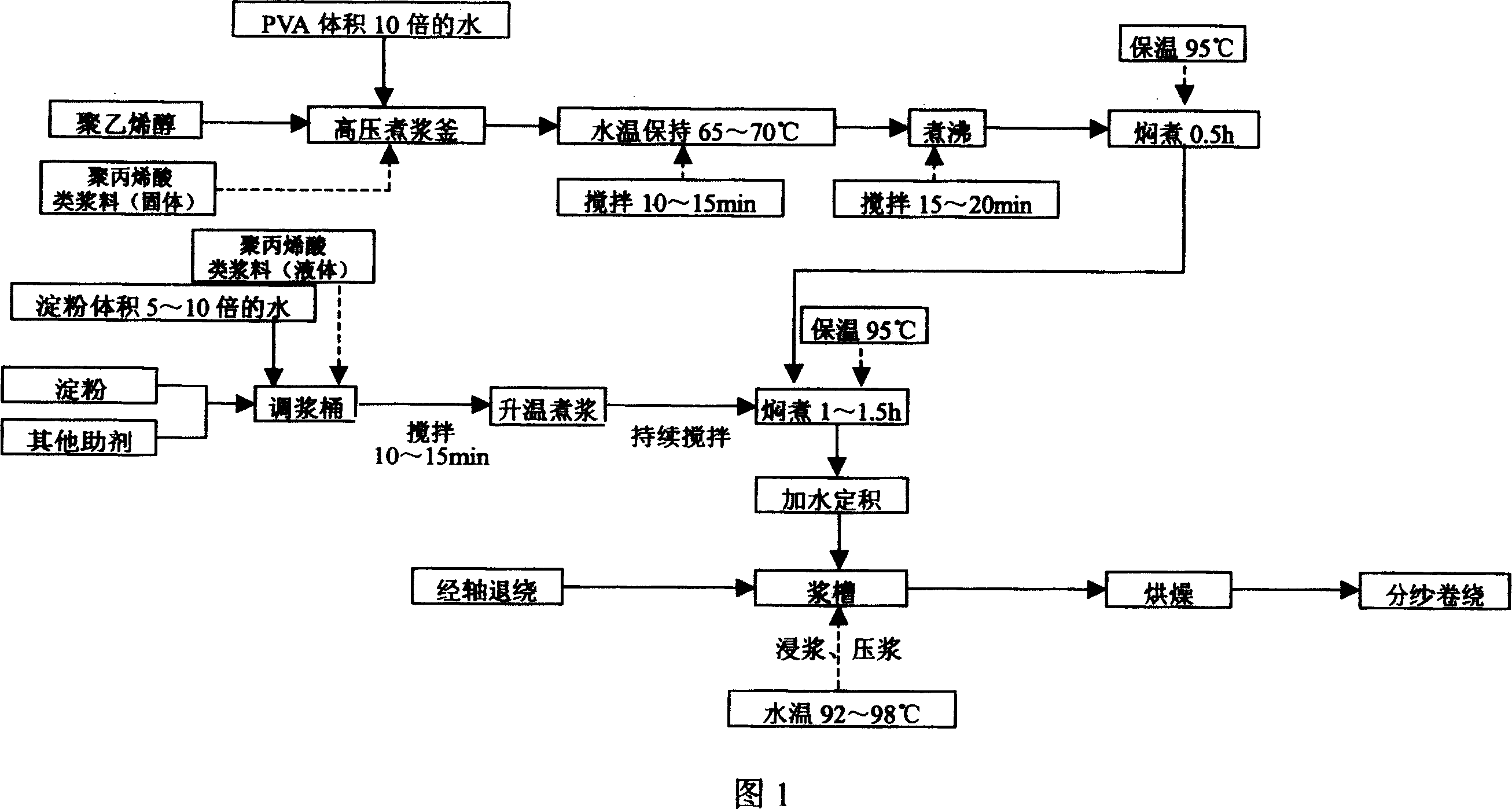

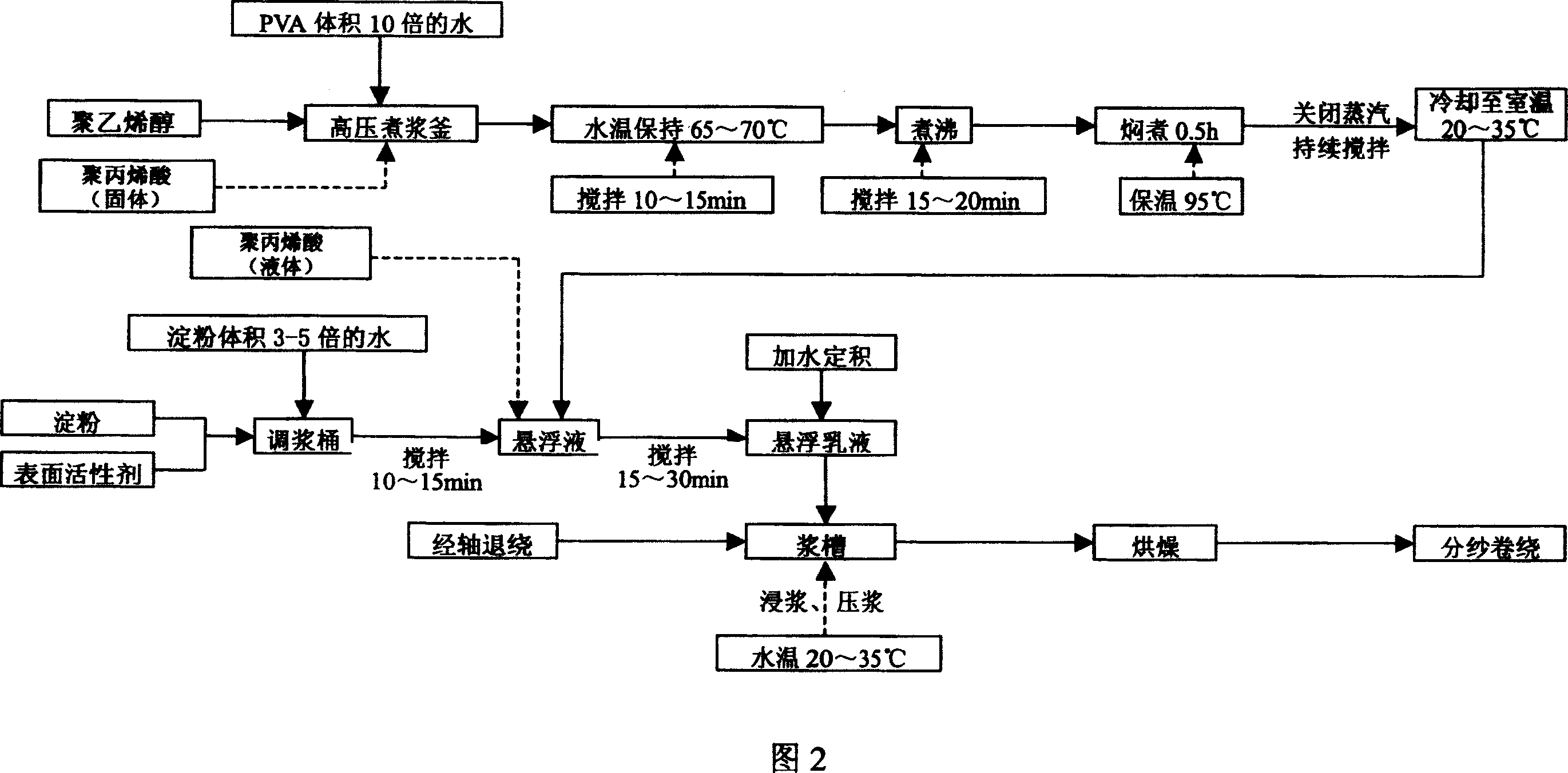

[0024] Embodiment 1: As shown in Figure 2, a method for warp yarn sizing directly using starch emulsion, including the steps of sizing and sizing.

[0025] 1), fabric specification

[0026] ●Fabric type: poplin fabric

[0027] Warp and weft yarn specifications: pure cotton carded 14.6×14.6 Tex

[0028] Warp and weft density: 523.5×283 threads / 10cm

[0029] ●Width: 121.9cm

[0030] 2), type of slurry

[0031] ●Corn oxidized starch 50kg

[0032] ●Polyacrylic slurry 9kg (liquid, 25% solid content)

[0033] ●Smoothing agent 1kg

[0034] 3), equipment

[0035] ●G921 type mixing tank

[0036] ●G924 Dissolving barrel

[0037] ●G925 type supply barrel

[0038] ●G146A-180 type sizing machine

[0039] ●GA615 loom

[0040] 4), mixing process

[0041] ● Modulation of starch suspension

[0042] Put water 3-5 times the volume of starch into the G921 mixing tank first, turn on the agitator (rotation speed is 36r / min), then slowly pour in starch and smoothing agent, continue sti...

Embodiment 2

[0053] Embodiment 2: As shown in Figure 2, a method for warp yarn sizing directly using starch emulsion, including the steps of sizing and sizing.

[0054] 1), fabric specification

[0055] ●Fabric type: khaki fabric

[0056] Warp and weft specifications: combed polyester cotton 16.3×16.3 Tex

[0057] Warp and weft density: 677×299 threads / 10cm

[0058] ●Width: 160cm

[0059] 2), type of slurry

[0060] ●Corn oxidized starch 100kg

[0061] ●Polyvinyl alcohol (PVA-1799) 10kg

[0062] ●Polyacrylic slurry 3kg (solid state)

[0063] ●Antistatic agent 2kg

[0064] 3), equipment

[0065] ●G921 type mixing tank

[0066] ●G924 Dissolving barrel

[0067] ●G925 type supply barrel

[0068] ●G146A-180 type sizing machine

[0069] ●GA615 loom

[0070] 4), mixing process

[0071] ●Prepare polyvinyl alcohol (PVA-1799) and polyacrylic acid slurry aqueous solution

[0072] Put water 10 times the volume of PVA into the G924 dissolving tank first, turn on the spiral agitator (rotati...

Embodiment 3

[0085] Embodiment 3: a kind of method that directly carries out warp yarn sizing with starch emulsion, comprises the step of modulating size liquid and warp yarn sizing,

[0086] 1), preparation of slurry:

[0087] (1), selection and preparation of slurry: slurry includes starch, polyacrylic acid and impregnating agent, polyacrylic acid accounts for 1% of starch dry weight, and impregnating agent accounts for 0.1% of the total weight of slurry (starch, polyacrylic acid and impregnating agent). %; polyacrylic acid is solid, and the solid polyacrylic acid is stewed in a high-pressure cooking kettle until it is completely dissolved into a solution, and then cooled to a room temperature of 20-35°C under continuous stirring for use;

[0088] (2) Serum preparation: first inject water 3 times the volume of starch into the mixing tank, and turn on the agitator at the same time, then add starch and soaking agent into the mixing tank, fully stir until it is in the form of a suspending e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com