Process for plasma strengthening type chemical vapour phase deposition treatment

A technology of chemical vapor deposition and processing method, which is applied in the field of plasma-enhanced chemical vapor deposition processing, can solve problems such as dielectric breakdown, reliability failure, and surface leakage, so as to avoid the formation of bumps, improve the pass rate, The effect of eliminating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

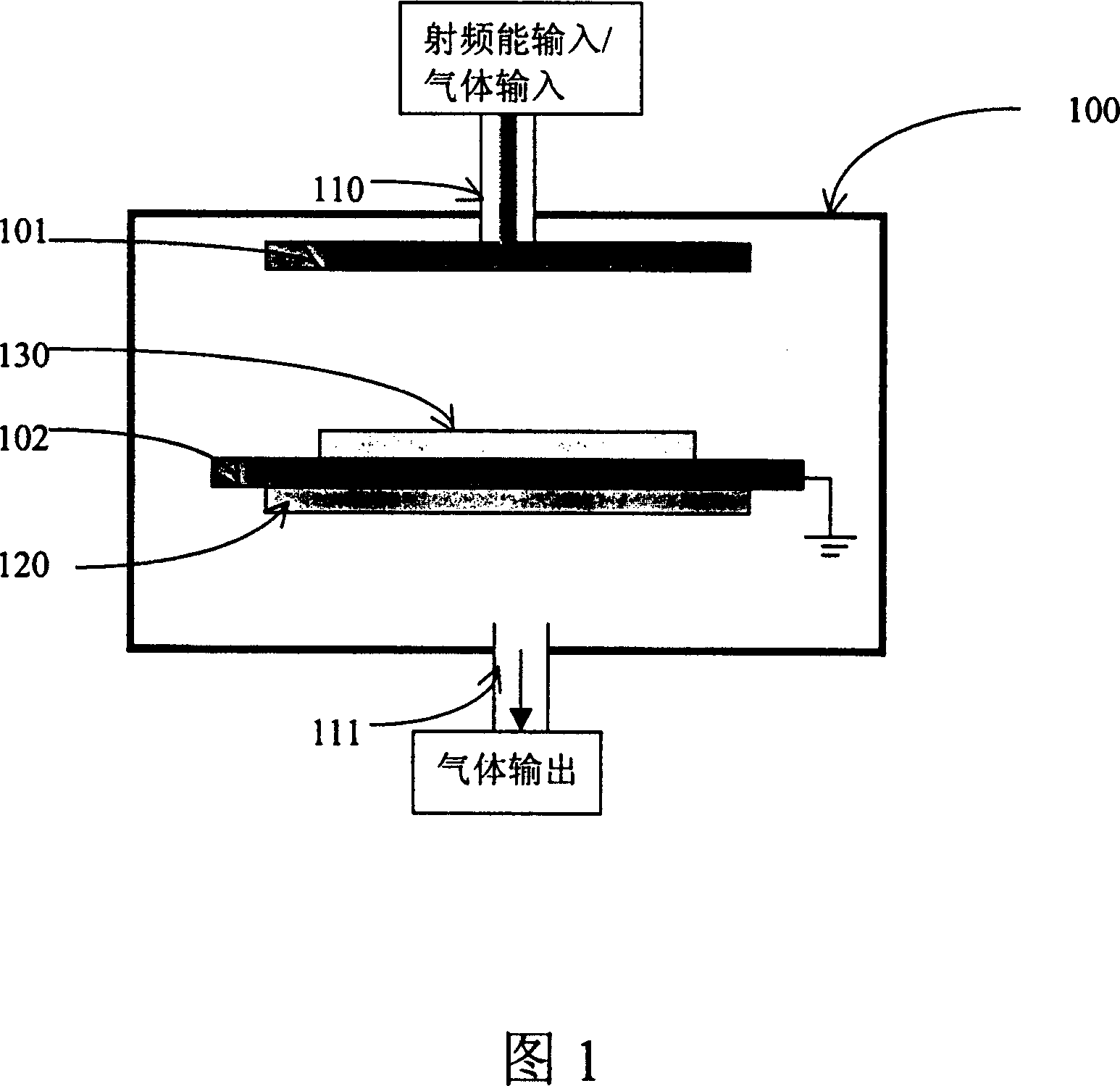

[0018] The PECVD method of the present invention still uses the reaction furnace 100 shown in FIG. 1 .

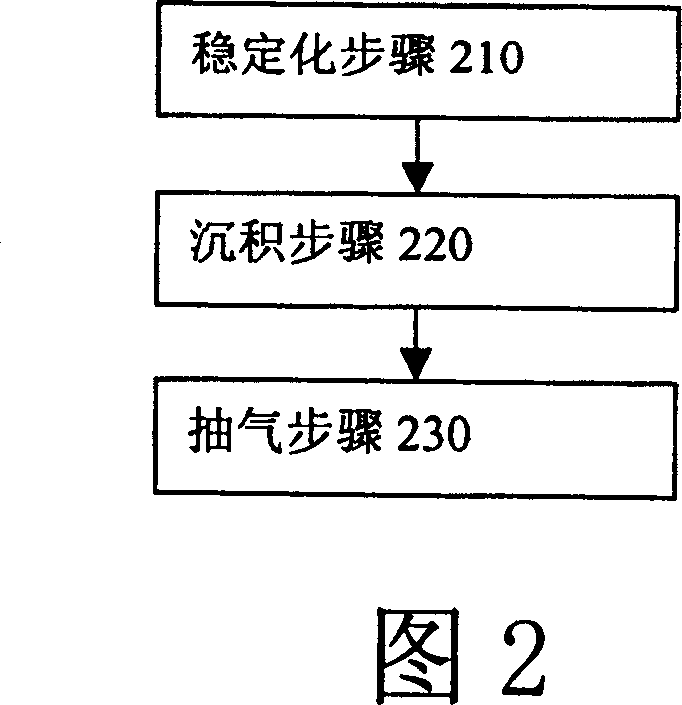

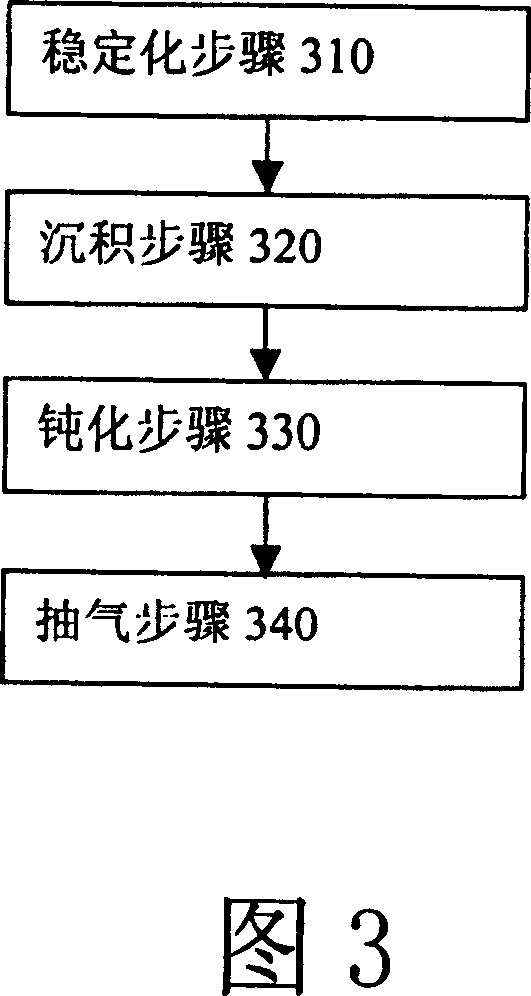

[0019] Fig. 3 is the flow chart of PECVD method according to the present invention, as can be seen by comparing Fig. 2 of traditional method, PECVD treatment method provided by the present invention has added a passivation between deposition step and pumping step with respect to traditional PECVD method transformation step. The specific steps of the PECVD method of the present invention will be described below with reference to FIG. 3 .

[0020] It can be seen from FIG. 3 that the PECVD treatment method provided by the present invention includes four steps.

[0021] First comes the stabilization step 310 . During this step, no RF energy is input. Just let the precursor gas such as NH 3 , N 2 O and N 2 , flow into the reaction furnace 100 at flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com