Method for purifying wet-process phosphoric acid by crystallization

A technology of wet-process phosphoric acid and crystallization, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high energy consumption and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

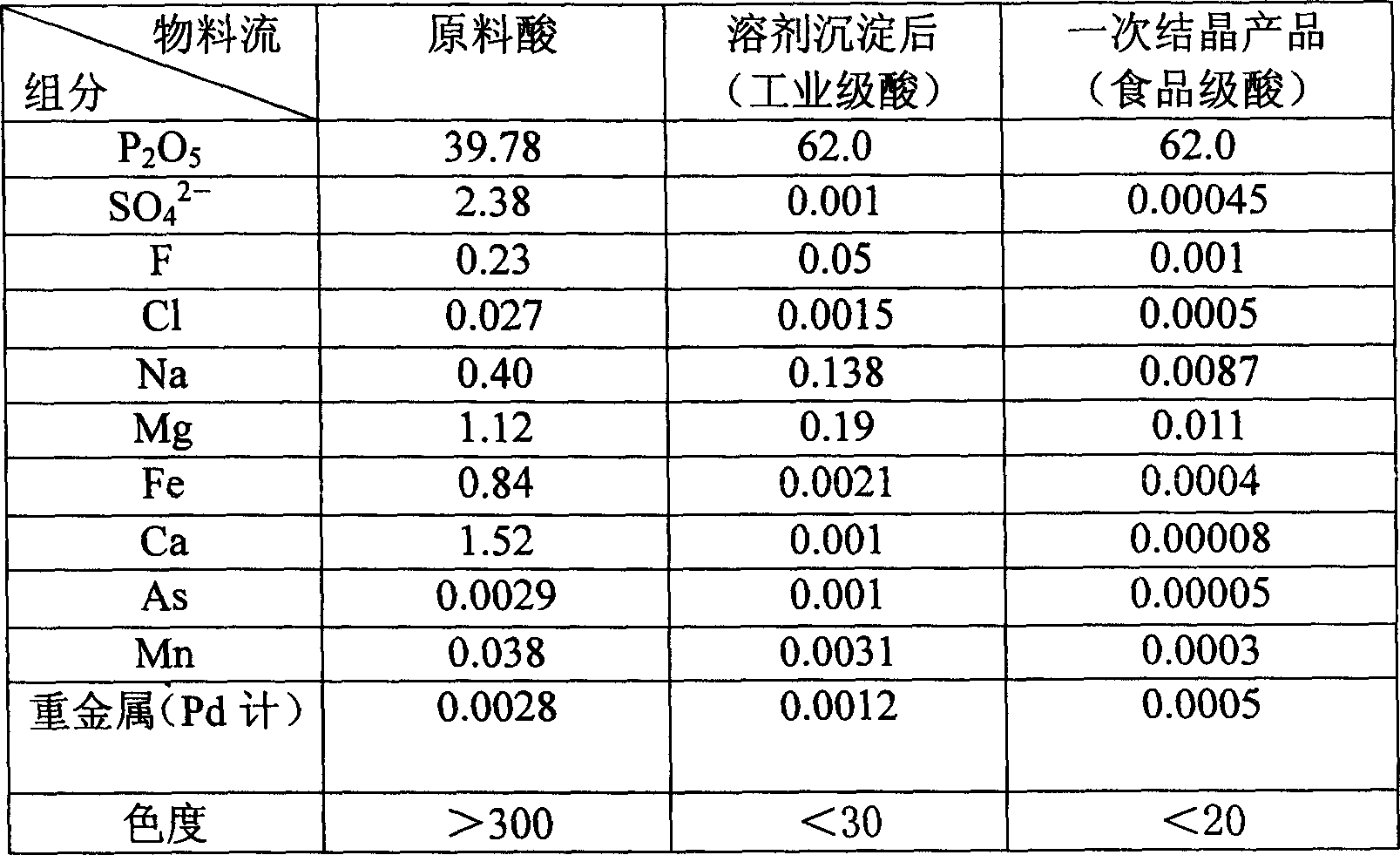

Embodiment 1

[0030] 600 g wet process phosphoric acid, P 2 O 5 Concentration 39.8%, add 5.4g CaO, 3.8g Na 2 S, 0.6 g of activated carbon and 0.6 g of diatomaceous earth, sealed and reacted for 2h. Suction filtration was separated to obtain 560 g of filtrate, P 2 O 5 Concentration 38.7%. The filtrate was heated and concentrated to 460 g, and NH was added with stirring. 3 5.3 g, the reaction temperature is 60~80 ℃, the reaction time is 0.5 hour, 1000 ml of isopropanol is added under rapid stirring, and the reaction is carried out for 10 minutes. The filtered residue was washed and dried to be used as fertilizer, and 20 ml of 20% NaOH solution was added to the mother liquor to stir and react, and the brine phase and the organic phase were separated after standing. The solvent in the organic phase was distilled to obtain 312 grams of acid solution, P 2 O 5 Concentration 55.2%; decolorized by activated carbon and concentrated to P 2 O 5 The concentration is 62% to obtain technical gra...

Embodiment 2

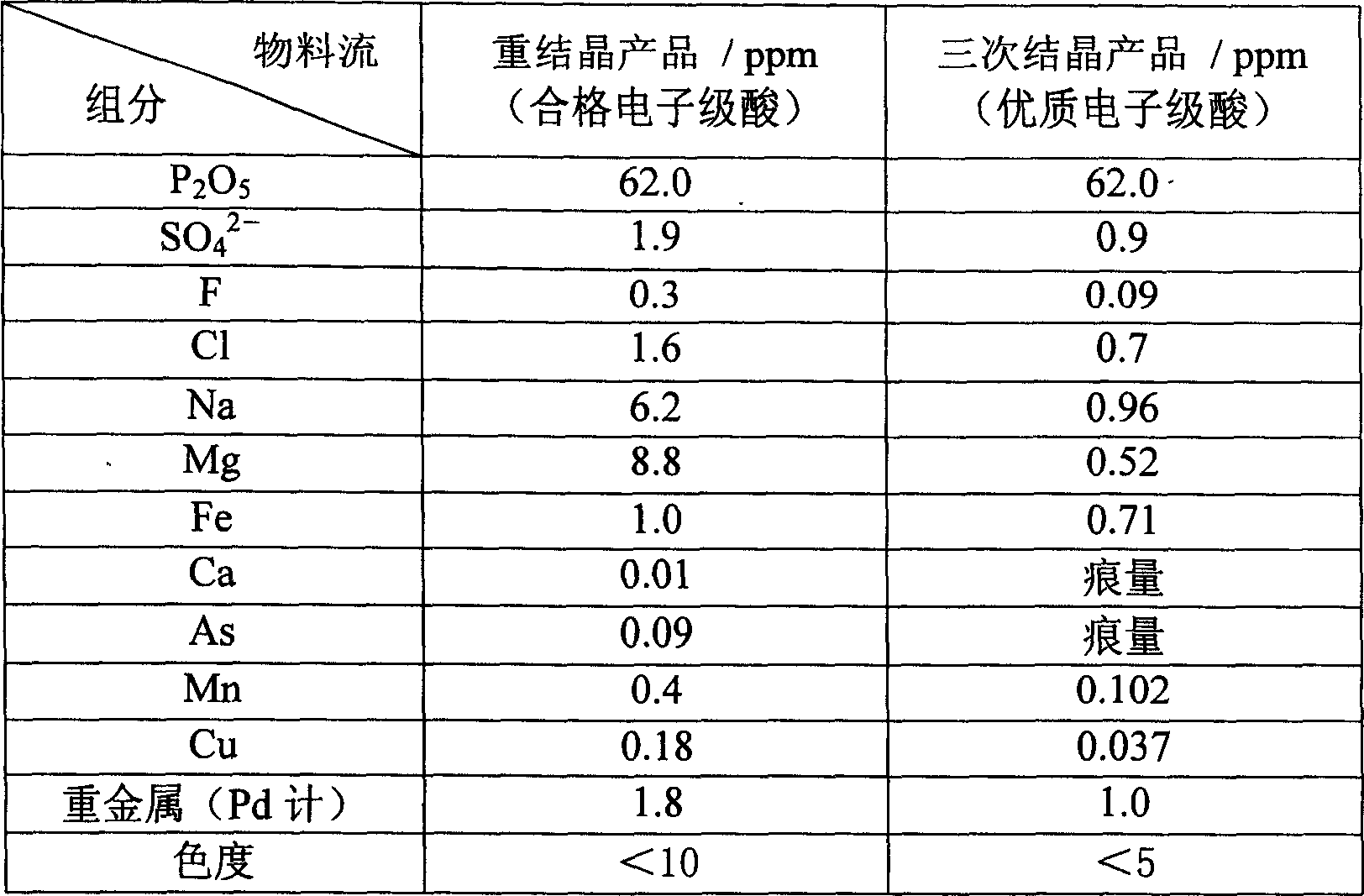

[0034] Embodiment 1 obtains 100 grams of phosphoric acid, P 2 O 5Concentration 63.9%, introduce 2.0 grams of crystallization agent at 15°C, keep the stirring speed at 200r.p.m, cool down to 5°C, operate for 5.0h, separate by suction filtration, and use 10 grams of next-stage crystallization mother liquor with a mass concentration of 80% for the filter cake Wash to obtain 47.6 grams of product, which can be used in the electronics industry after melting and dilution, and the composition is listed in Table 2. This step crystallization operation P 2 o 5 The mass yield is 49.0%, and the mother liquor and washing liquid are mixed with the aforementioned food-grade purification acid.

Embodiment 3

[0036] Embodiment 2 gets phosphoric acid 45 grams, P 2 o 5 Concentration 63.9%, introduce 0.9 g of crystallization agent at 10°C, keep the stirring speed at 160r.p.m, cool down to 2°C, operate for 6.0h, separate by suction filtration, and wash the filter cake with 5 g of high-purity phosphoric acid with a mass concentration of 80%. Obtain product 21.0 grams, melt and dilute to obtain high-quality electronic grade phosphoric acid, composition is also listed in Table 2. This step crystallization operation P 2 o 5 The mass yield is 48.6%, and the mother liquor and washing liquid are mixed with the aforementioned qualified electronic-grade purification acid.

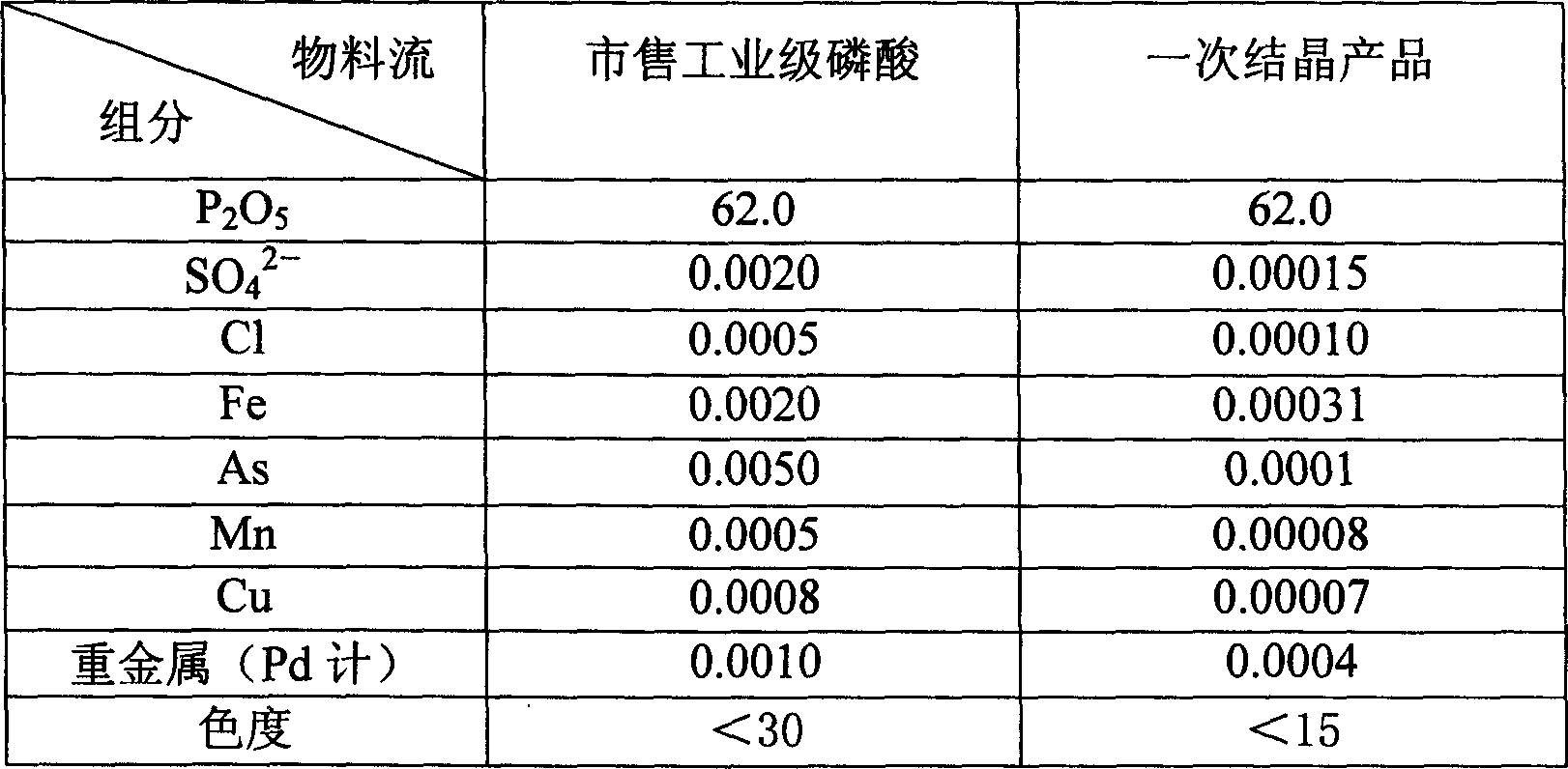

[0037] Table 2 Material flow composition (%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com