Axial triangular through groove type pure water hydraulic throttle valve

A throttle valve and triangular technology, which is applied in the direction of fluid pressure actuators, fluid pressure actuator system components, servo motor components, etc., can solve problems such as difficulty in guaranteeing precision, unobtainable, long throttle channel, etc., and achieve work Reliable, easy to adjust, low adjustment force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

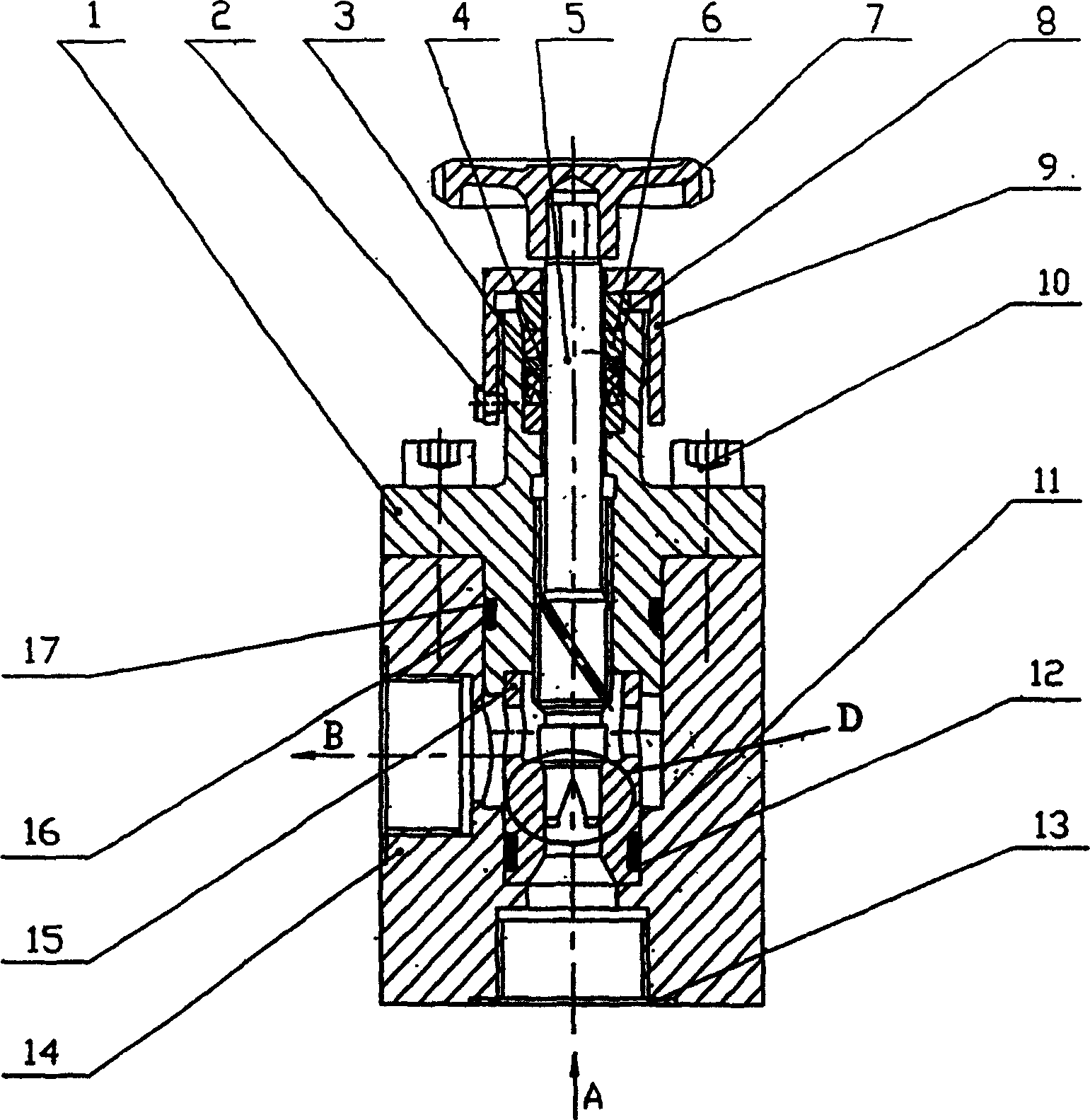

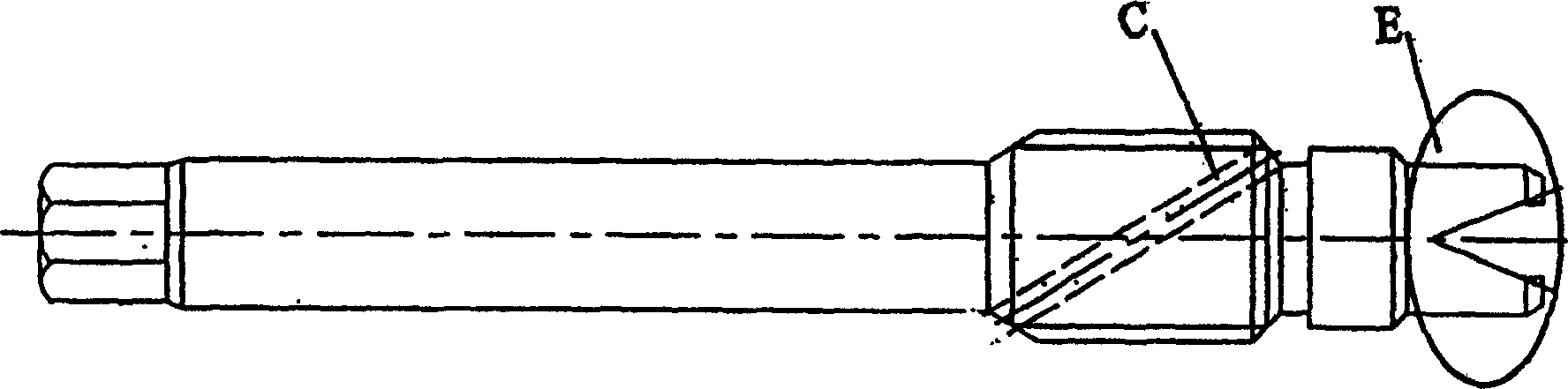

[0018] Such as figure 1 , figure 2 As shown, the present invention is equipped with a valve sleeve 15 at the center of the valve body 14, and the lower end of the valve body 14 and a side are respectively provided with a water inlet A and a water outlet B, and the water inlet A at the lower end of the valve body 14 passes through the lower end hole of the valve sleeve 15 and a side surface. The hole communicates with the water outlet B on one side of the valve body 14; the valve body 14 is equipped with a flange 1, the throttle spool 5 is installed in the valve body 14 and the flange 1, and the lower end of the throttle spool 5 is provided with an axial triangular connection. The throttling valve port of the slot E is matched with the valve sleeve 15, and the oblique pressure balance hole C is opened in the middle shaft of the throttle spool 5 and is matched with the hole of the flange 1, and the throttle spool 5 outside the flange 1 is installed There is an adjustment hand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com