Bottle cleaner for cleaning recovered bottles

A glass bottle cleaning and bottle cleaning agent technology, which is applied in cleaning methods and utensils, cleaning hollow objects, inorganic non-surface-active cleaning compositions, etc., can solve the problems of cleaning and recovery bottle corrosion, blurred and opaque bottles, and poor brightness of washed bottles and other problems, to achieve the effect of obvious consumption reduction gain, prolonged washing cycle and high bottle cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

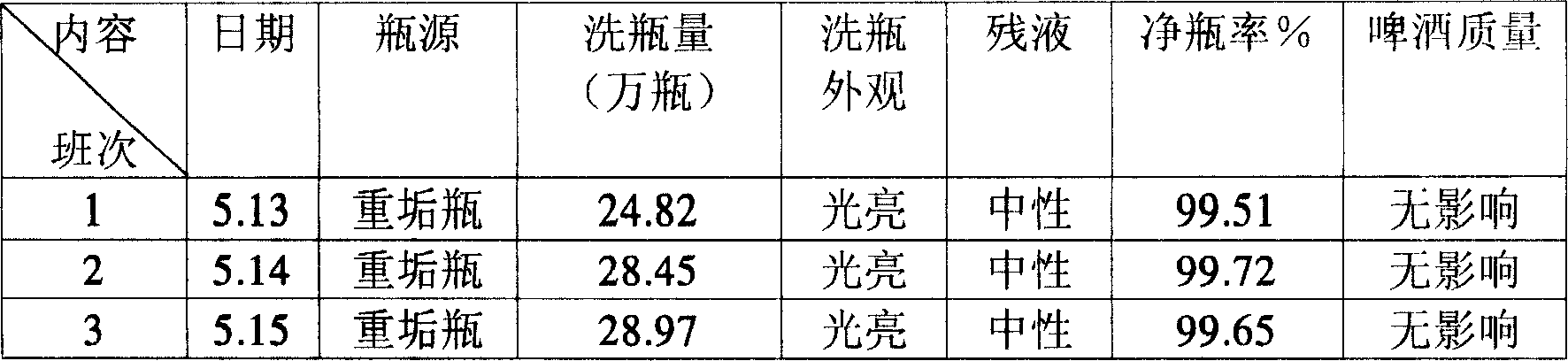

Image

Examples

Embodiment 1

[0011] 76 grams of caustic soda, 11 grams of sodium carbonate, 7 grams of sodium metasilicate, 4 grams of sodium gluconate, and 2 grams of nitrilotriacetic acid sodium salt (A92R) are mixed to form solid component A;

[0012] 2 grams of fatty alcohol polyoxyethylene ether, 7 grams of nonylphenol polyoxyethylene ether, 1 gram of fatty alcohol polyoxyethylene ether sulfate, 5 grams of organic solvent, 11 grams of sodium polyphosphate, 2 grams of silicone defoamer, water 72 grams were mixed uniformly to make microemulsion water base B.

Embodiment 2

[0014] 85 grams of caustic soda, 5 grams of sodium carbonate, 3 grams of sodium metasilicate, 2 grams of sodium gluconate, and 5 grams of nitrilotriacetic acid sodium salt (A92R) are mixed to form solid component A;

[0015] 3 grams of fatty alcohol polyoxyethylene ether, 5 grams of nonylphenol polyoxyethylene ether, 2 grams of fatty alcohol polyoxyethylene ether sulfate, 4 grams of organic solvent, 8 grams of sodium polyphosphate, 1 gram of silicone defoamer, water 77 grams were mixed evenly to make microemulsion water base B;

[0016] Add a certain amount of clear water to the cleaning tank, add 1.5% A and 1.5% B by weight; when the solution in the cleaning tank is heated to 75-80°C, it will be washed in bottles; during the washing process, as the number of bottles increases and To prolong the time, add 0.3% A and 0.3% B by weight when the ms value drops to the range of 50-60. When the sodium aluminate content is determined to be greater than 3%, the washing residue is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com