Peach storing method

A technology of low-temperature storage and ethylene, which is applied in the direction of freezing/refrigerating preservation of fruits/vegetables, food preservation, and fresh-keeping of fruits and vegetables, which can solve the problems of post-ripening and loss of flavor synthesis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Eight mature peaches were selected for picking, and stored under controlled atmosphere after pre-cooling at a storage temperature of 0-2°C. Artificially increase ethylene gas in the controlled atmosphere storage, the concentration range of ethylene is 5-50ul / l, keep this concentration until the end of storage. Since the controlled atmosphere storage is not absolutely airtight, the ethylene concentration in the storage will gradually decrease. When the ethylene concentration is lower than 5ul / l, it needs to be replenished.

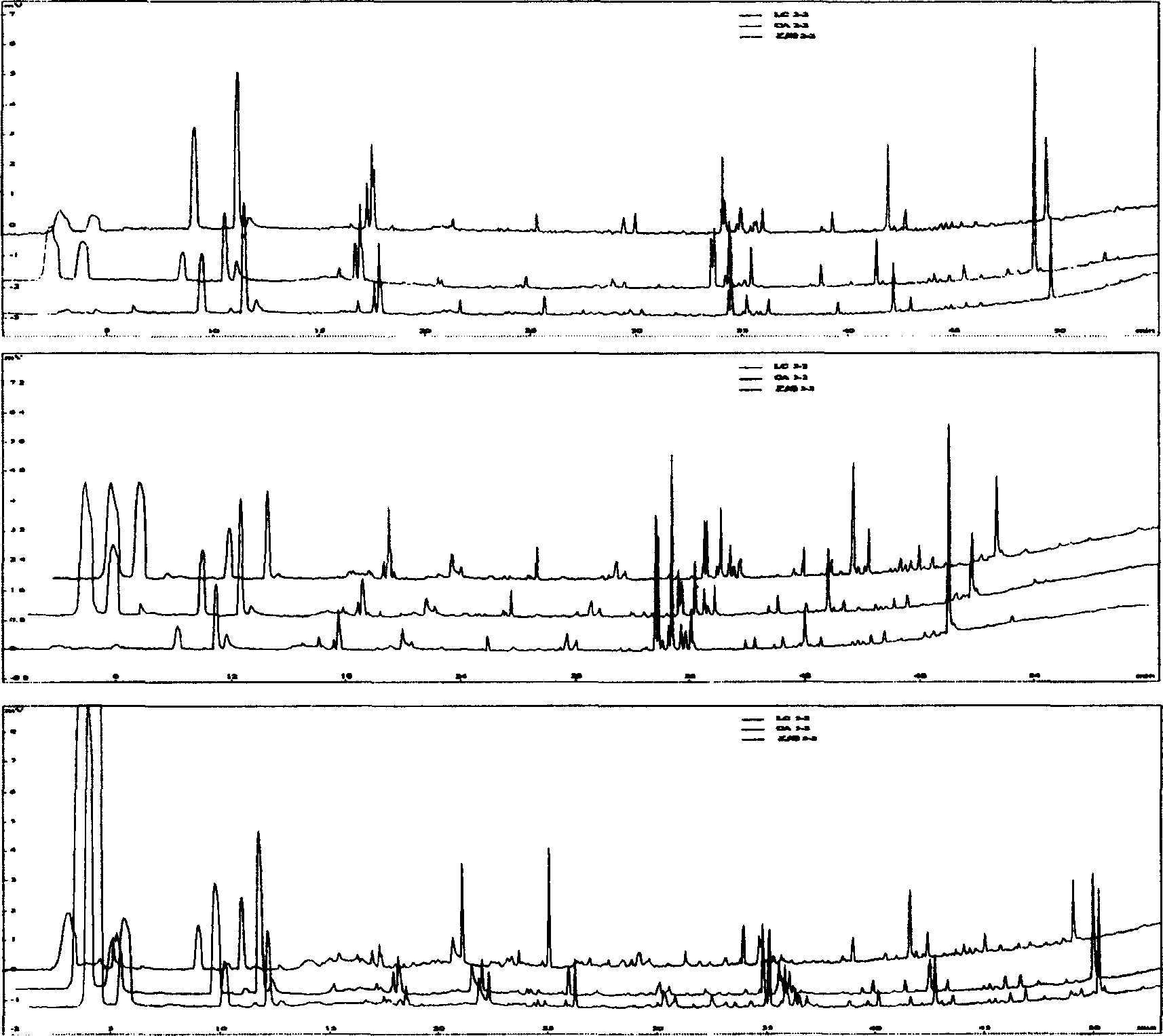

[0012] Changes of Main Volatile Aromatic Substances in Peach Fruit

[0013] Figure 1, Figure 2 and Figure 3 are the GC spectra of peach fruits stored for 10 days, 30 days and 50 days respectively. It is found that peach fruits treated with high-concentration exogenous ethylene wake-up technology maintain good flavor during each storage stage. The study also showed that high-concentration exogenous ethylene awakening technology to treat peach fruit b...

Embodiment 2

[0016] Eight mature peaches were selected for picking, and stored under controlled atmosphere after pre-cooling at a storage temperature of 0-2°C. Spray the ethephon solution on the surface of the fruit so that the concentration range of conversion to ethylene is 5-50ul / l, and keep this concentration until the end of storage. After storage for 60 days, the browning rate of the fruit was 85.8% lower than that of the control, indicating that the coloring degree increased by 78.6%.

Embodiment 3

[0018] Eight ripe peach fruits are picked and refrigerated after pre-cooling at a storage temperature of 0-2°C. Spray the ethephon solution on the surface of the fruit so that the concentration range of conversion to ethylene is 5-50ul / l, and keep this concentration until the end of storage. After storage for 60 days, the browning rate of the fruit was 80.5% lower than that of the control, indicating that the coloring degree increased by 75.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com