Three-in-one cleaning agent

A cleaning agent, cleaning agent technology, applied in the field of cleaning agents, can solve the problems of human and environmental hazards, environmental pollution, high risk, etc., and achieve the effect of not being easy to misuse, convenient for storage and transportation, and shortening the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of three-in-one cleaning agent

[0032] recipe one

[0033] Component Weight percent (%)

[0034] Inorganic acid Phosphoric acid 40

[0036] Chelating agent Sodium gluconate 5

[0037] Inorganic salt additive NaF 0.2

[0038] CaCl 2 1.0

[0039] Surfactant TX-10 0.2

[0040] Defoamer 0.05

[0041] water balance

[0042] recipe two

[0043] Component Weight percent (%)

[0044] Inorganic acid Phosphoric acid 15

[0045] Zinc salt Zinc dihydrogen phosphate 0.5

[0046] Chelating agent Citric acid 2

[0047] Inorganic salt additive Na 2 SiF 6 0.1

[0048] Ca(NO 3 ) 2 2.5

[0049] Surfactant OP-10 0.5

[0050] Defoamer 0.07

[0051] water balance

[0052] According to the weight percentage given in the above formula, first mix the zinc salt and water evenly, then add phosphoric acid under the condition of water cooling, stir unt...

Embodiment 2

[0053] Embodiment 2 The example of cleaning pipelines in a circular manner

[0054] In a new chemical plant in a factory, the pipes of the plant were cleaned before being put into operation. The dirt in the pipes was mainly anti-rust grease, floating rust and welding slag.

[0055] Pipeline volume: 25m 3 Material: carbon steel, stainless steel

[0056] Scaling situation: Grease and rust are attached to the pipe wall, and there is a small amount of welding slag at the bottom.

[0057]Cleaning agent dosage

[0058] Three-in-one cleaning agent 2.5T prepared according to formula 1 in Example 1

[0059] cleaning process

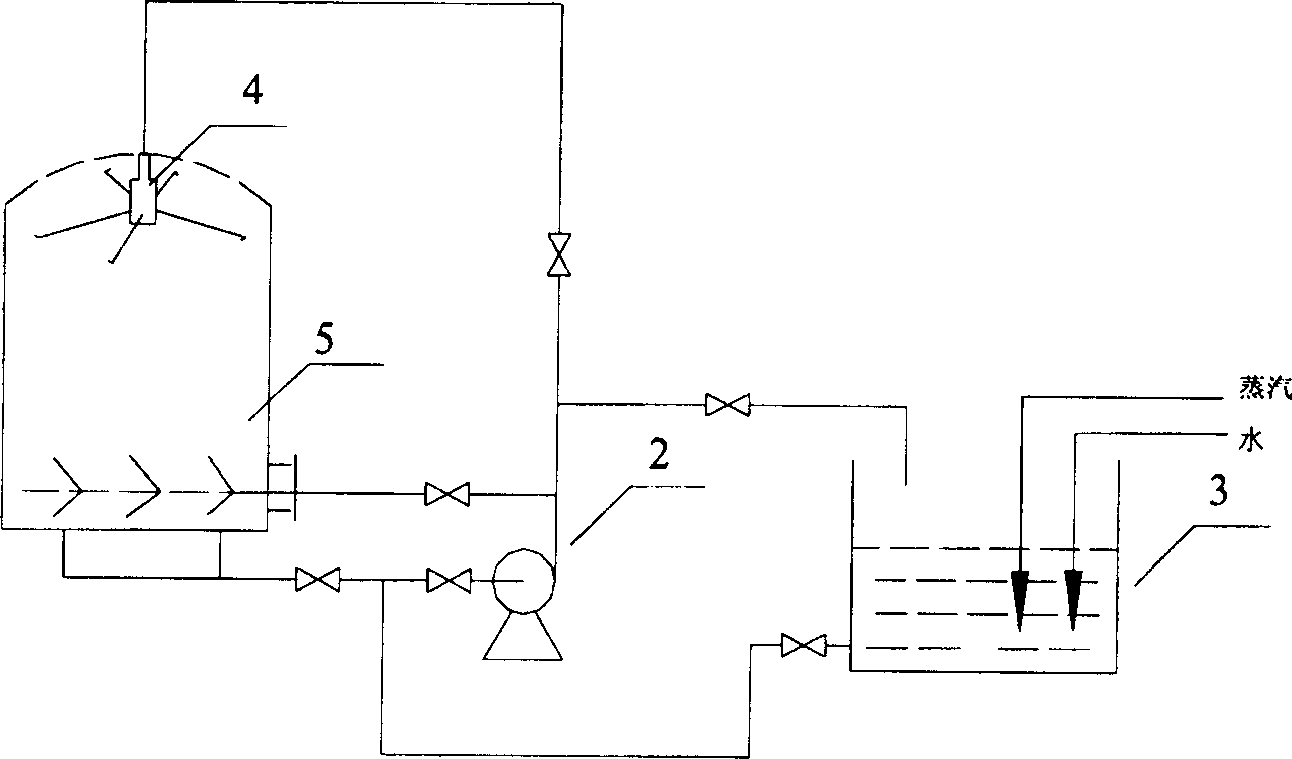

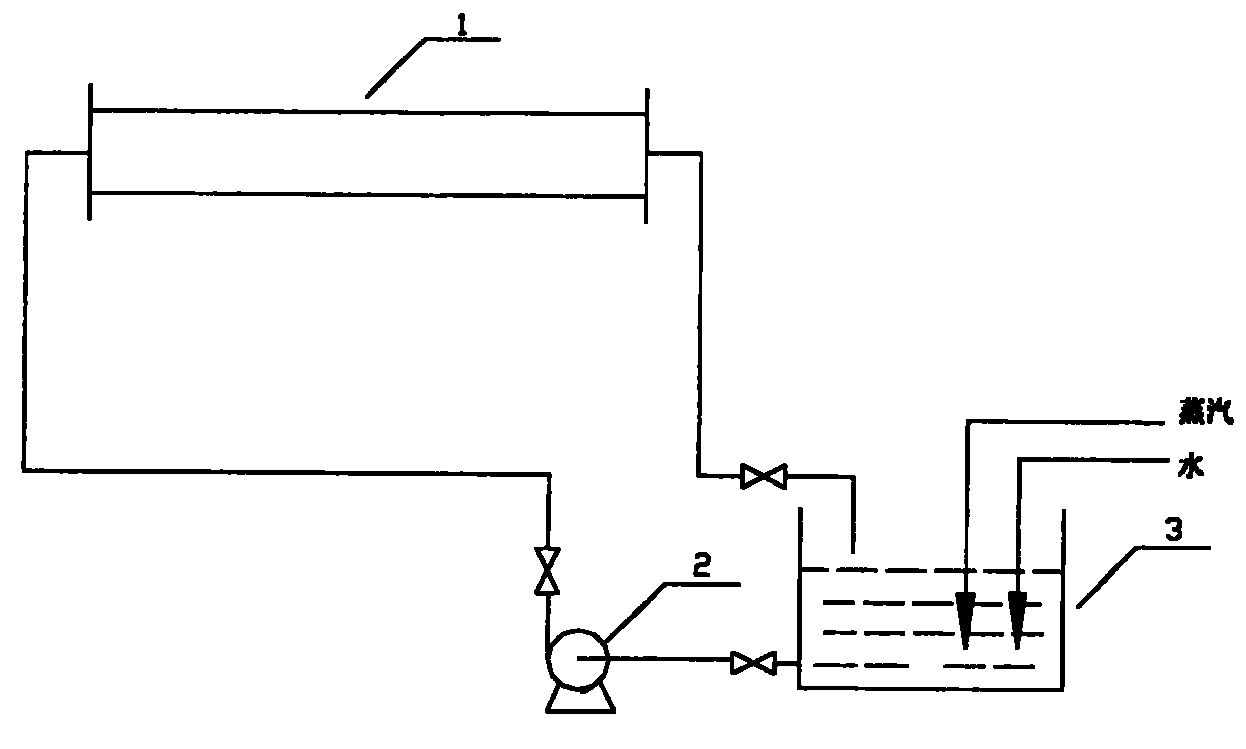

[0060] according to figure 1 The process flow shown is through line cycle cleaning, figure 1 Among them, 1 is the pipeline system to be cleaned, 2 is the circulating pump, and 3 is the liquid distribution tank.

[0061] First add 22.5m of water to the liquid distribution tank 3 , the test run pump will not cause evacuation, and there is liquid r...

Embodiment 3

[0066] Embodiment 3 The example of cleaning the storage tank by spraying

[0067] A company built a new storage tank for organic chemical raw materials. Because the raw materials contained in it have high requirements on the cleanliness of the container, and the inner surface of the new tank has a certain amount of floating rust, a small amount of welding slag and other impurities are also produced during the installation process. It meets the requirements of use, and the three-in-one cleaning agent of the present invention is used to spray and clean the storage tank before use.

[0068] Tank volume: 500m 3 Tank diameter: 8m

[0069] Tank height (including head): 11m Tank material: carbon steel

[0070] Scaling of the storage tank: the bottom of the tank is oxidized iron scale and dust and other sundries, with a thickness of 1 to 3, and the inner wall of the tank is floating rust, which is relatively thin.

[0071] Cleaning agent dosage

[0072] The three-in-one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com