Heat-engine plant circulating water classified concentration series using process

A technology of circulating water and thermal power plants, applied in the direction of ion exchange water/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problems of large amount of sewage and unsatisfactory results, and achieve the effect of reducing the amount of waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples illustrate the invention.

[0026] This embodiment takes the graded concentration and serial use of the circulating cooling water of four units in a certain power plant as an example.

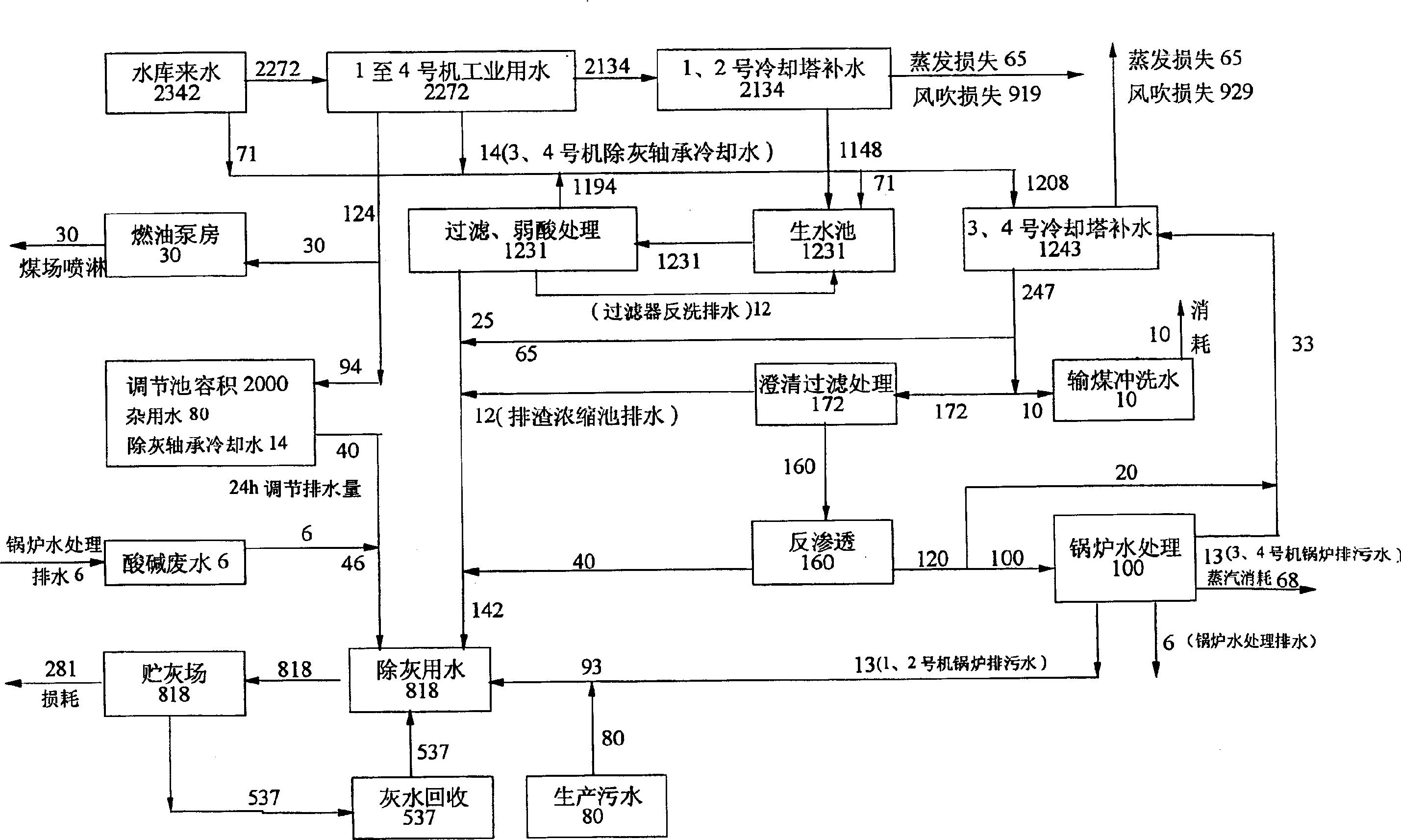

[0027] The flow chart of this embodiment is attached image 3 give.

[0028] Example Description:

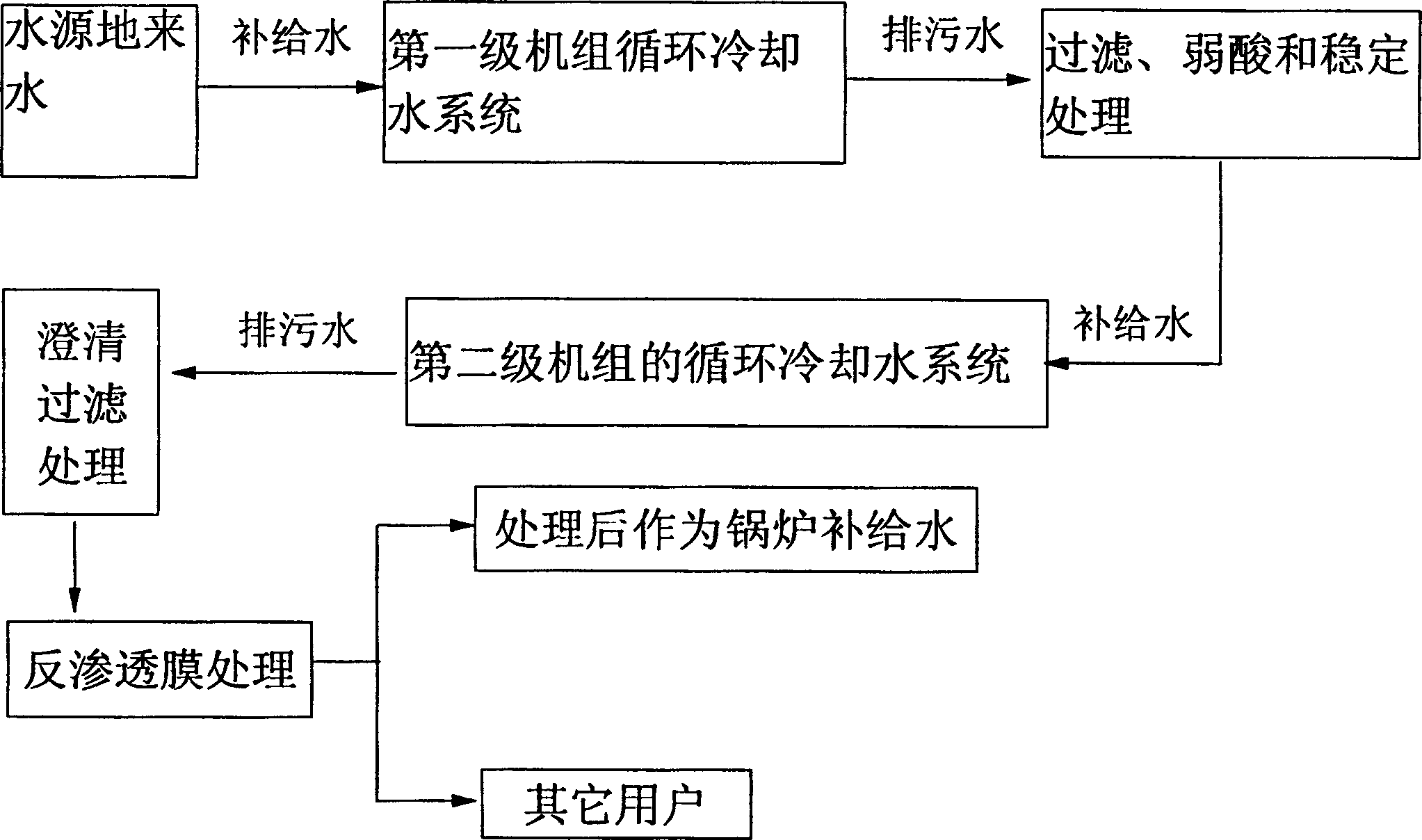

[0029] The four units are rated to operate at full load. The water from the reservoir (water from the source) is used by the industrial system and enters the circulating water system of Units 1 and 2. The circulating water of Units 1 and 2 is operated at a low concentration ratio, and the concentration ratio is 1.76. The sewage was treated by weak acid ion exchange as circulating supply water for Units 3 and 4. The circulating water of Units 3 and 4 was operated with a high concentration ratio of 3.86, and the total concentration ratio of circulating water was 6.79. The sewage was clarified, filtered and After reverse osmosis membrane treatment, it is used as raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com