Method for preparing biologic diesel oil by using halophytic vegetation as raw material

A technology for halophyte and biodiesel, which is applied in the preparation of biological raw materials, liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of high price and high cost, achieve low production costs, reduce operating costs, and meet energy needs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

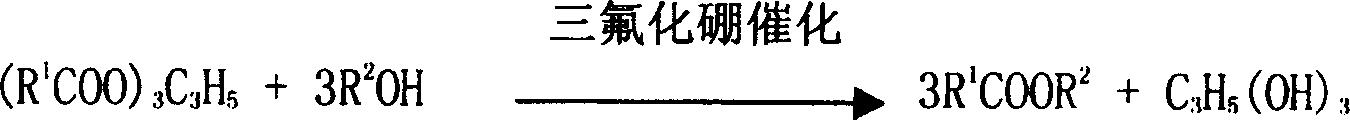

Embodiment 1

[0037] Embodiment 1. Take 500g of Suaeda salsa seeds, add them to the reactor after processing, and add 300g of methanol, at room temperature, continue to stir vigorously until the material forms a suspension with uniform flow. 60g of catalyst (46.8% boron trifluoride / methanol) was added to the mixture and reacted at 65°C for 2h under slow stirring and reflux. The reaction mass was cooled to 40° C. and filtered to obtain 400 g of solid phase and 460 g of filtrate. The filtrate was distilled at atmospheric pressure, and 320g of crude methanol condensate was recovered. There was 140g of liquid residue in the distiller, which was a mixture of methyl esters, glycerin and other by-products. The residue was left for 2 hours to room temperature (25° C.), separated into two phases, and the lower layer was 14 g of crude glycerol, and the upper layer was 126 g of methyl ester, which could be used as biodiesel fuel after purification. The solid phase was vacuum dried, and 40 g of methan...

Embodiment 2

[0038] Embodiment 2, take 500g salicornia seeds, add into the reactor after processing, 300g methanol, at room temperature, continue to stir vigorously, until the material forms the suspension that flows evenly. 60g of catalyst (46.8% boron trifluoride / methanol) was added to the mixture and reacted at 65°C for 2h under slow stirring and reflux. The reaction mass was cooled to 40° C. and filtered to obtain 350 g of solid phase and 510 g of filtrate. The filtrate was distilled at atmospheric pressure, and 320g of crude methanol condensate was recovered. There was 160g of liquid residue in the distiller, which was a mixture of methyl esters, glycerin and other byproducts. The residue was allowed to stand for 2 hours to room temperature (25° C.), separated into two phases, and the lower layer was 16 g of crude glycerol, and the upper layer was 144 g of methyl ester, which could be used as biodiesel fuel after purification. The solid phase was vacuum dried, and 50 g of methanol an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com