Method for processing and producing surface with degree of lustre

A technology for extrusion tools and surface hardness, which is applied in the direction of manufacturing tools, presses using rotating pressure members, presses, etc., and can solve problems such as no disclosed embodiments or special application purposes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

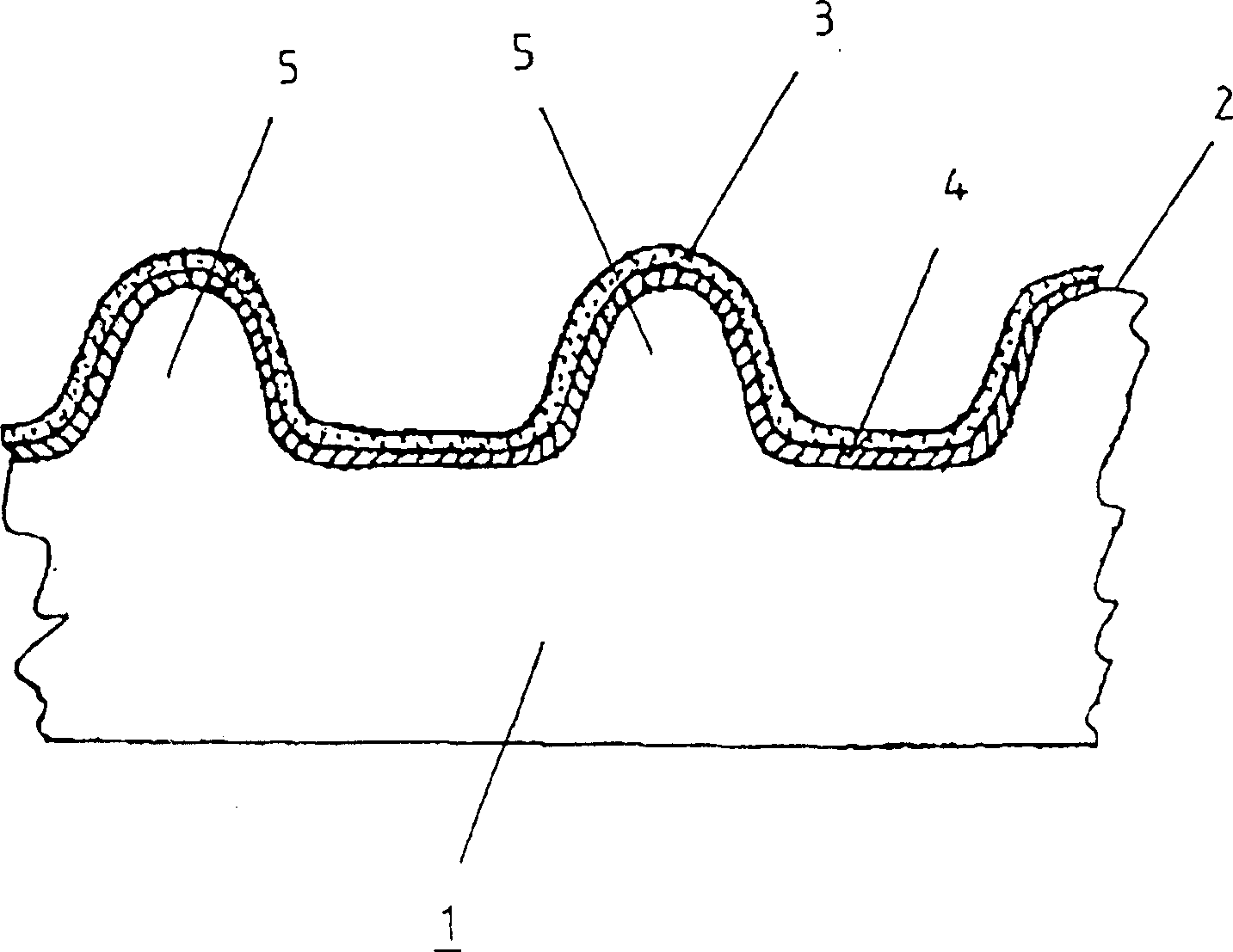

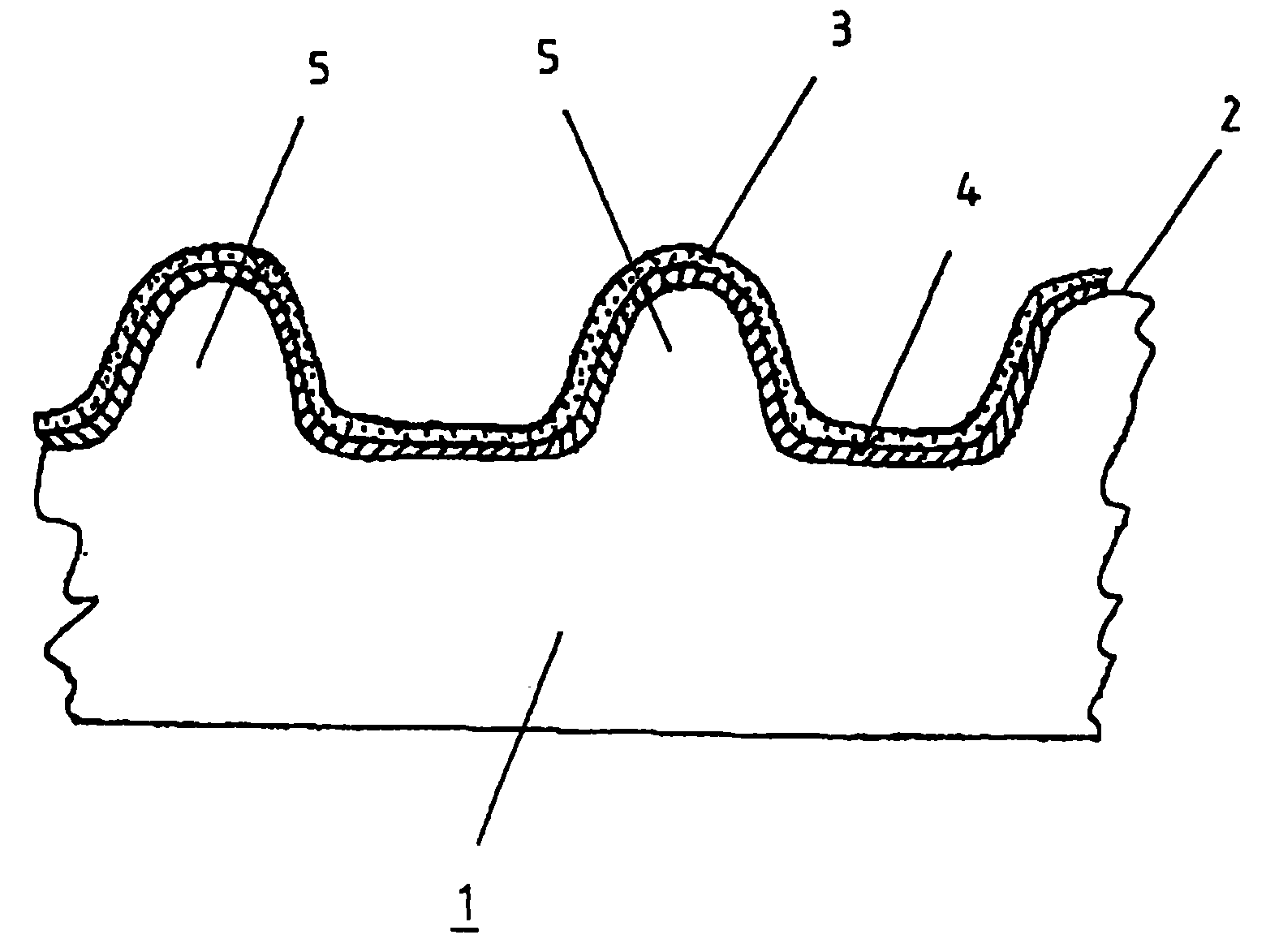

[0019]The extrusion tool 1 is preferably used for the production of plastic-coated wood or laminated panels, which are used, for example, in the production of furniture. For surface structuring, the pressing tool 1 can have a pressed structure 5 on its surface. The pressing of such a structure 5 in the material to be processed is achieved by means of a pressing tool 1 in the form of a large-sized pressing plate or a continuous strip, which consists of a steel or brass plate with a surface texture or comprises a steel or brass plate with copper or Brass coated steel sheet. Here, the surface structure is produced in a further coating. This is then optionally provided with hard chrome plating and results in the coating 3 according to the invention. Such an extrusion tool 1 is inserted into an extrusion device, by means of which plastic-coated furniture panels, laminated panels, etc. are produced. For continuous production, extrusion machines are also known in this connection w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com