Optical fiber laser group beam laser

A fiber laser and laser technology, applied in the direction of lasers, laser devices, laser components, etc., can solve the problems of complex optical path, large loss of optical energy, low system stability, etc., and achieve the effect of simple optical path and reduced optical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

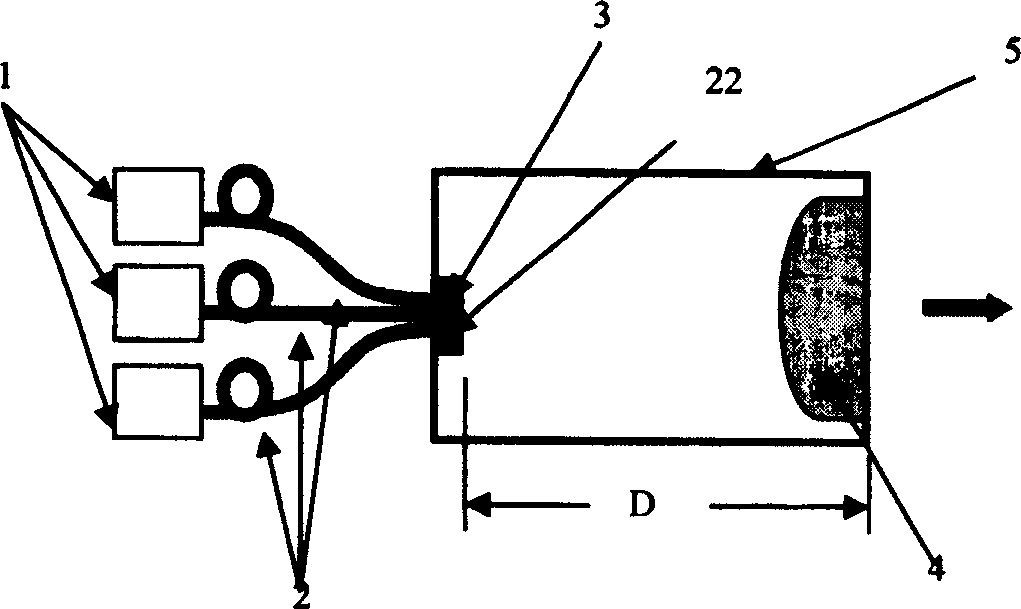

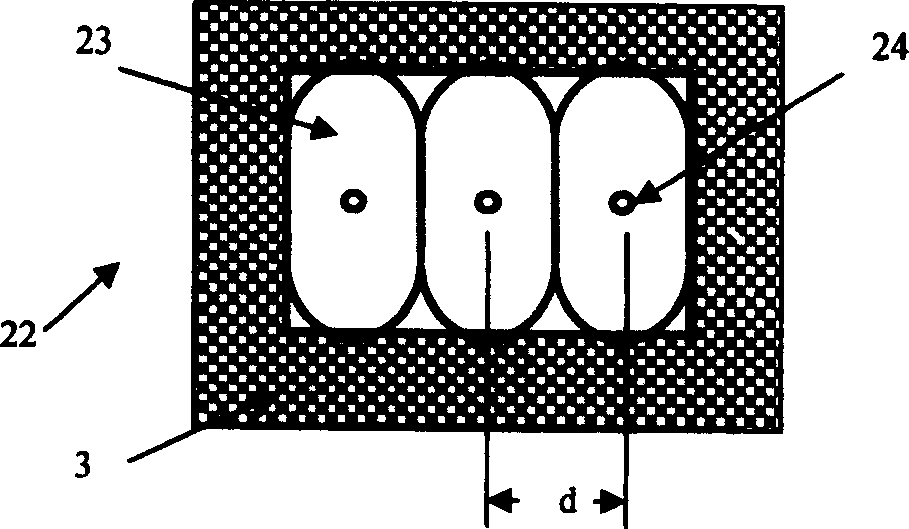

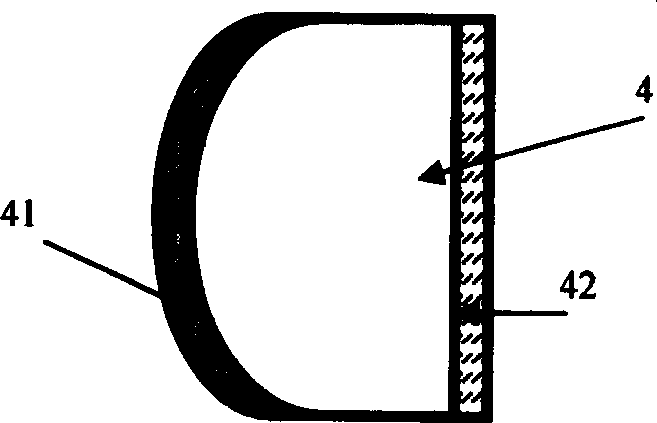

[0012] see first figure 1 , figure 1 It is a structural schematic diagram of the fiber laser bundle laser used in the present invention. As can be seen from the figure, the fiber laser bundle laser of the present invention comprises a plurality of double-clad optical fibers 2, and one end of each double-clad optical fiber 2 is respectively connected to a pump laser 1, and is characterized in that the plurality of double-clad optical fibers After the outer cladding is removed from the other end of the optical fiber 2, the line array is closely arranged in the optical fiber holder 3 to form a flat optical fiber array output end face 22 and placed in one end of a resonant cavity box 5, and the other end of the resonant cavity box 5 is provided with a plano-convex lens 4. The convex surface of the plano-convex lens 4 is coated with an anti-reflection film 41, and the plane is coated with a semi-transparent reflective film 42 toward the outside of the resonant cavity box 5. Form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com