Light conducting plate and its preparing process

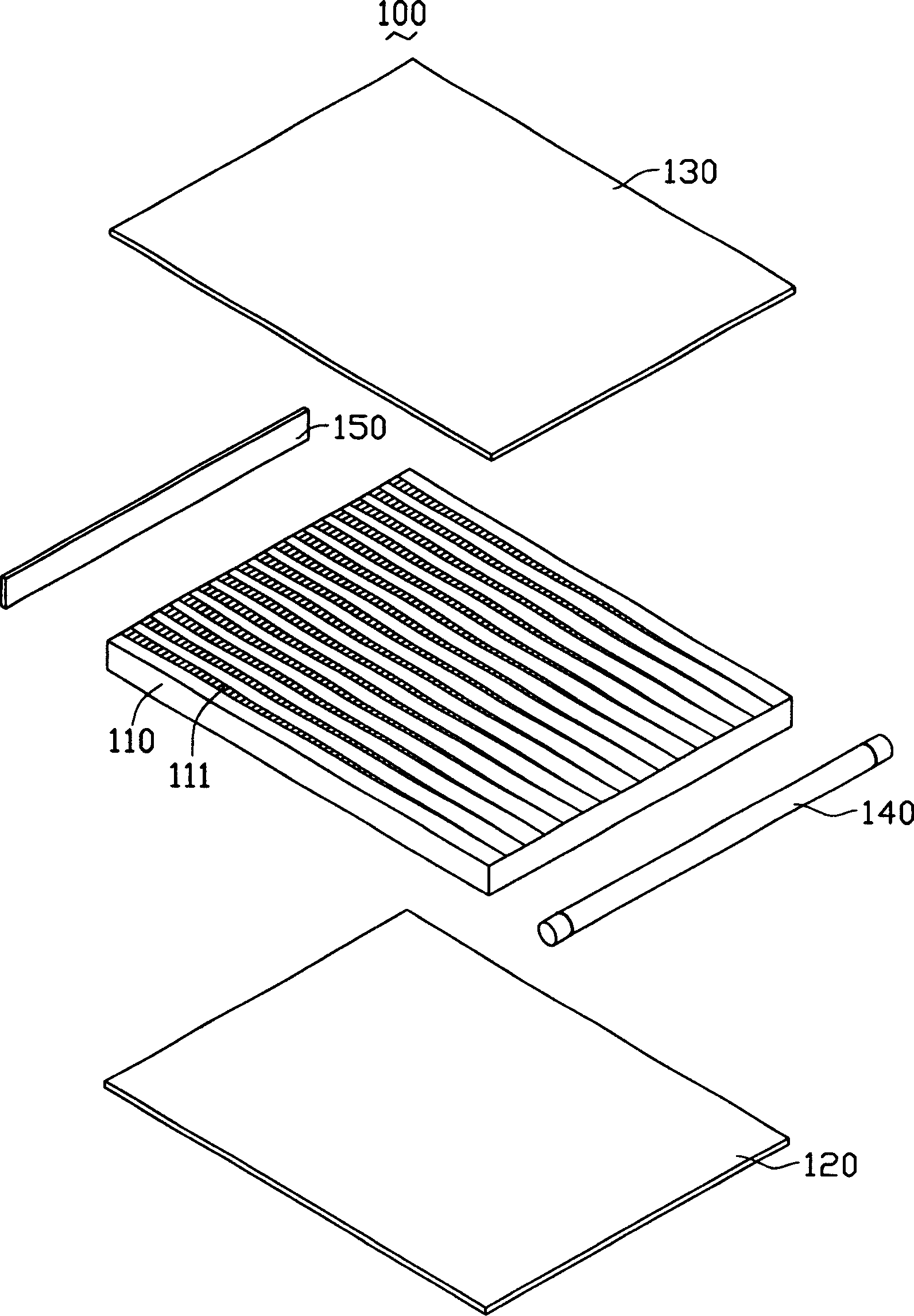

A manufacturing method and technology for a light guide plate, which are applied in optics, nonlinear optics, instruments, etc., can solve the problem that the light guide plate cannot make the light evenly distributed, and achieve the effect of reducing the light transmission interface, low light loss, and improving the brightness of the light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

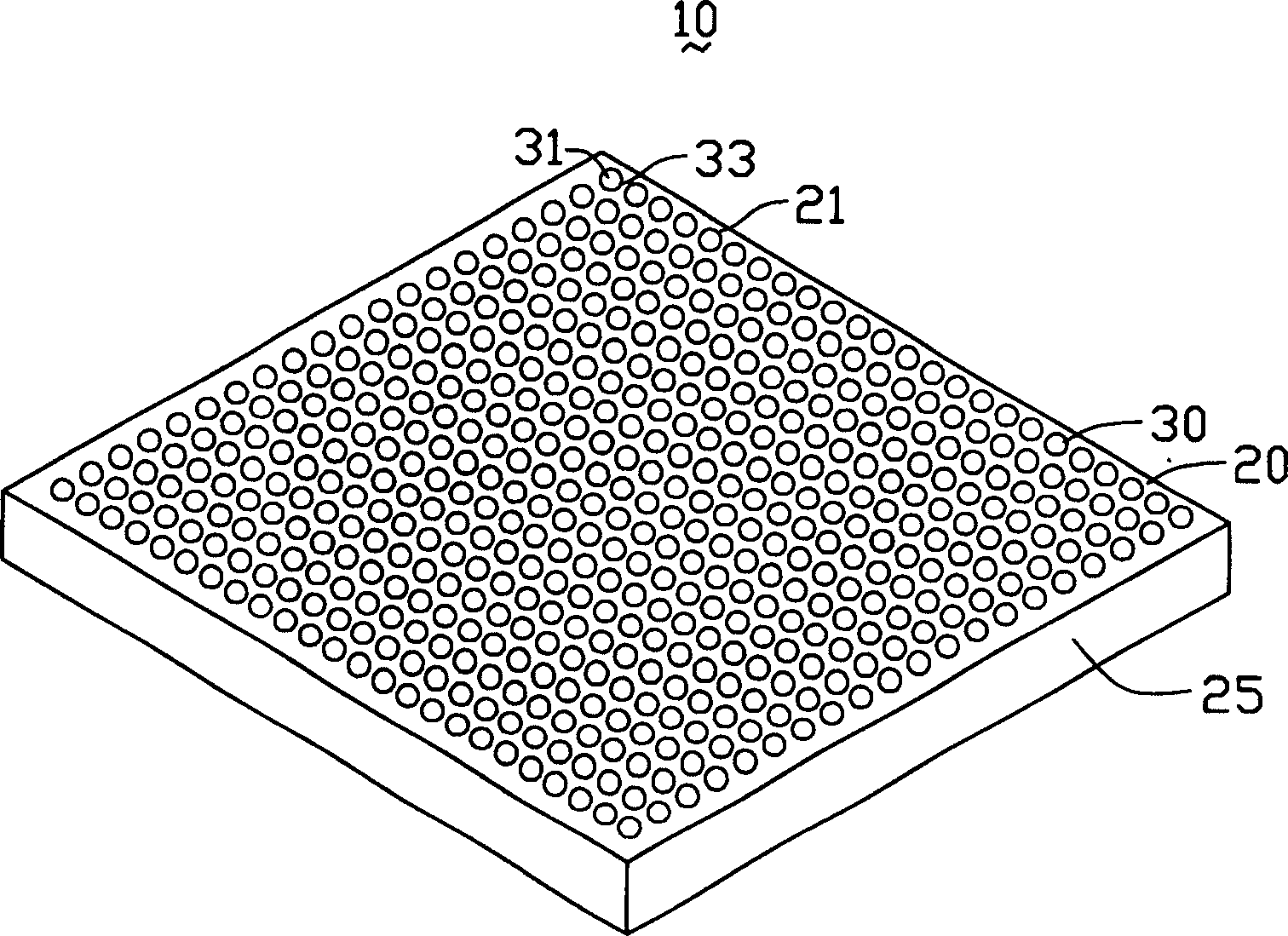

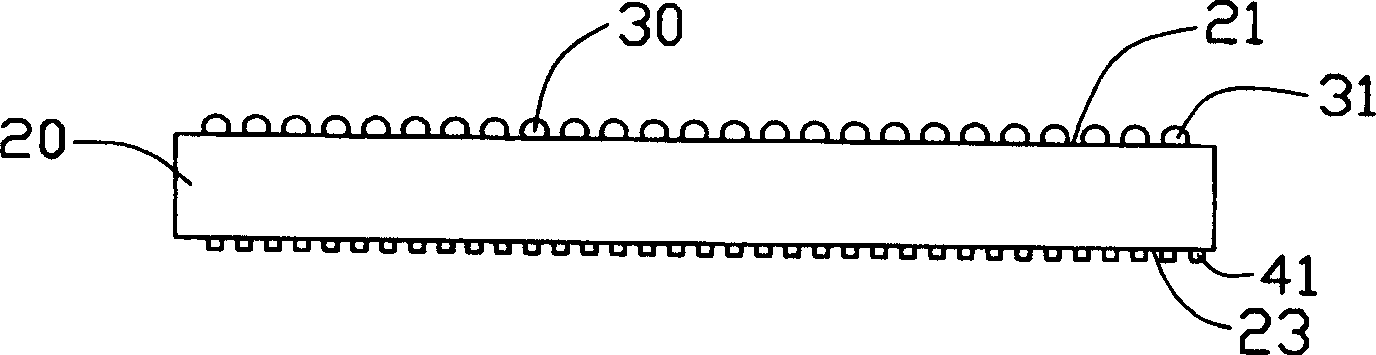

[0017] see figure 2 , which is the first embodiment of the present invention, the light guide plate 10 of the present invention includes a light-transmitting plate 20 and a light-diffusing structure 30 . The light-transmitting plate 20 is made of transparent resin material or glass, and it includes a light incident surface 25, a light exit surface 21 and a bottom surface 23 (such as image 3 shown), wherein the light exiting surface 21 is opposite to the bottom surface 23, and both the light exiting surface 21 and the bottom surface 23 intersect the light incident surface 25.

[0018] Please refer to figure 2 , image 3 with Figure 4 , the light-emitting surface 21 of the light-transmitting plate 20 is provided with a light-diffusing structure 30 . The light diffusing structure 30 includes organic filler spheres 31 and a binder 33 , which can diffuse the light beam emitted from the light emitting surface 21 to improve uniformity. The organic filler spheres 31 are unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com