Container yard high-low crane relay type loading-unloading system

A container yard and loading and unloading system technology, which is applied in the field of relay-type loading and unloading systems for high and low cranes in container yards, can solve problems such as low productivity and poor compatibility of container trucks, and achieve improved loading and unloading speed, high-efficiency loading and unloading advantages, and improved efficiency and technology horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

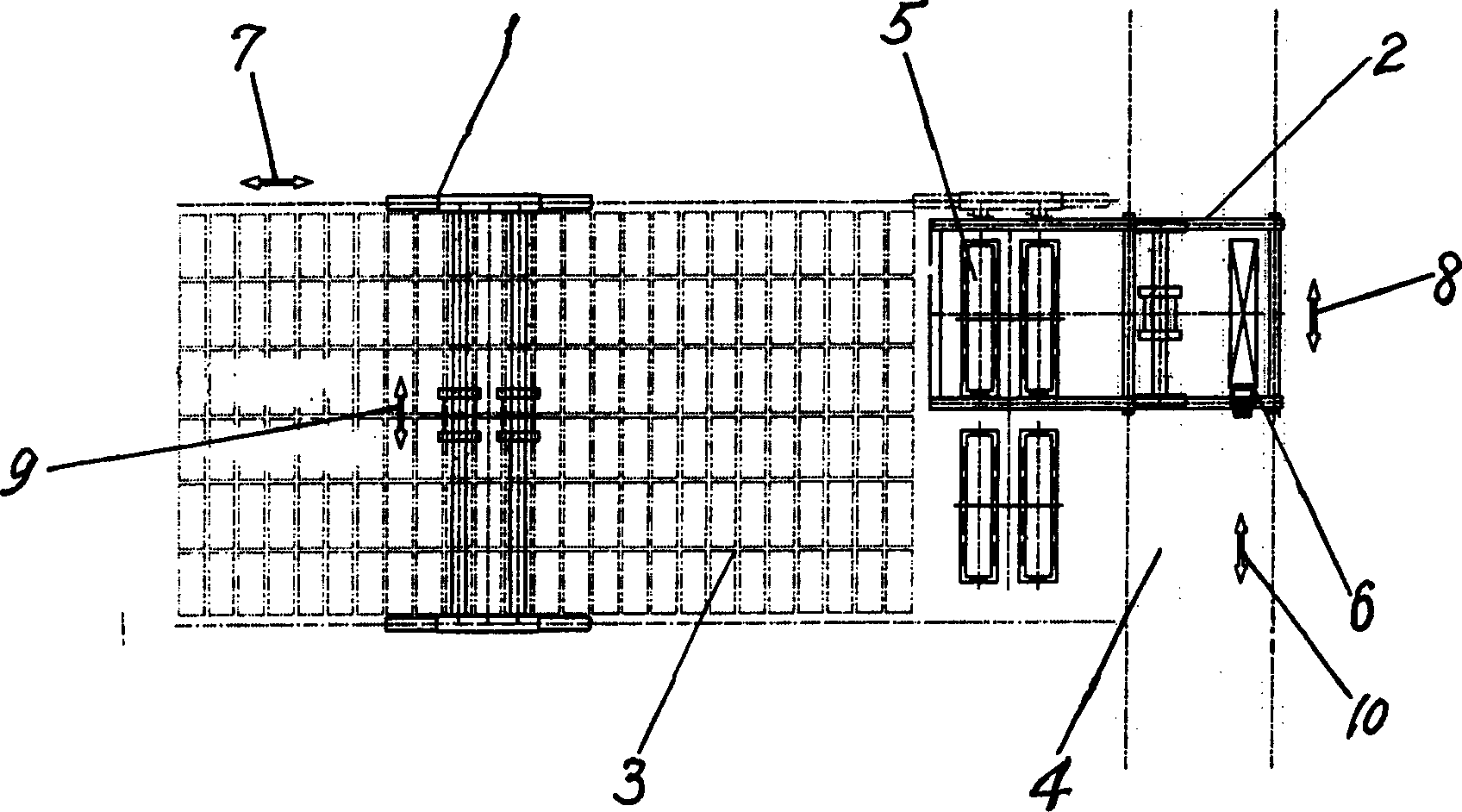

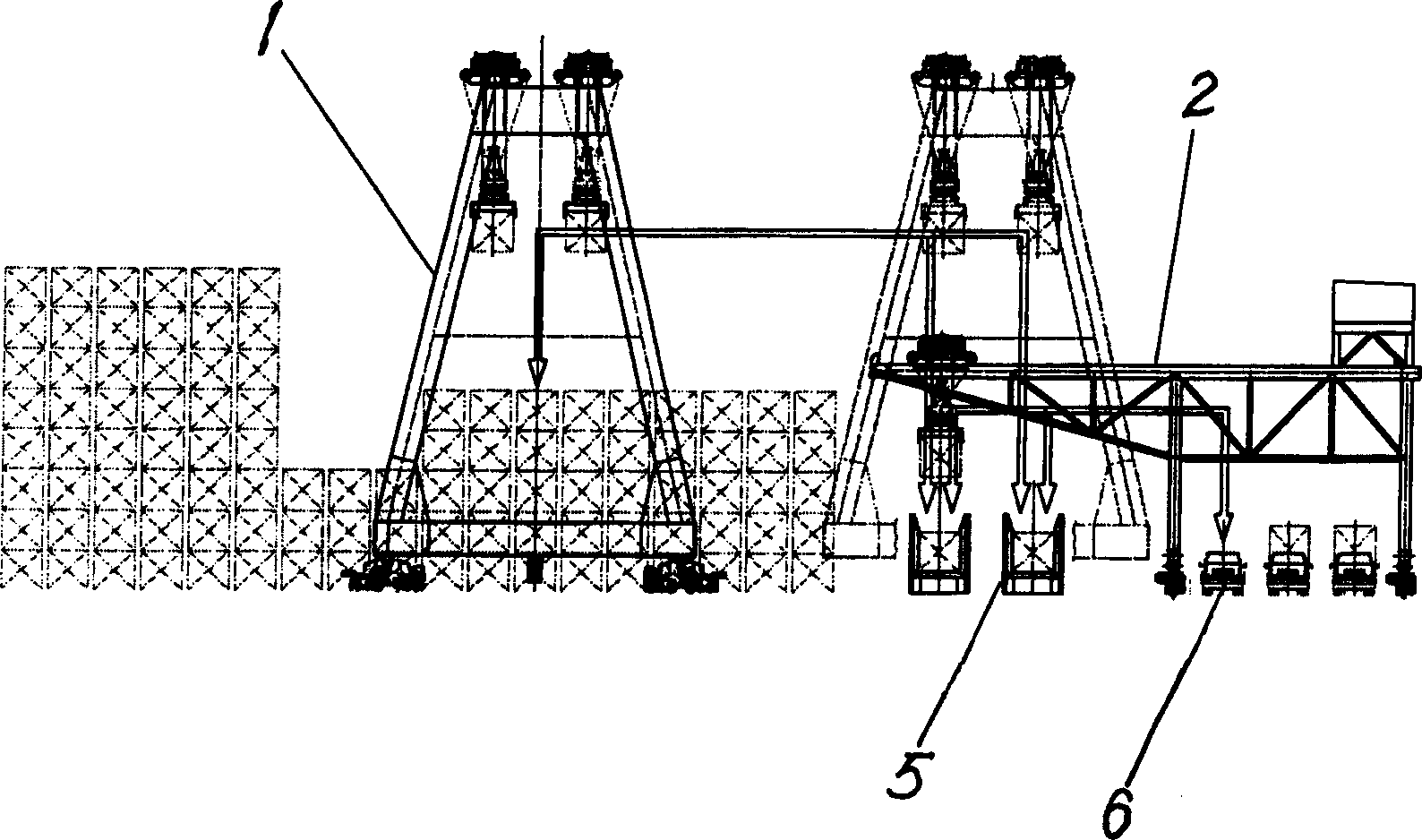

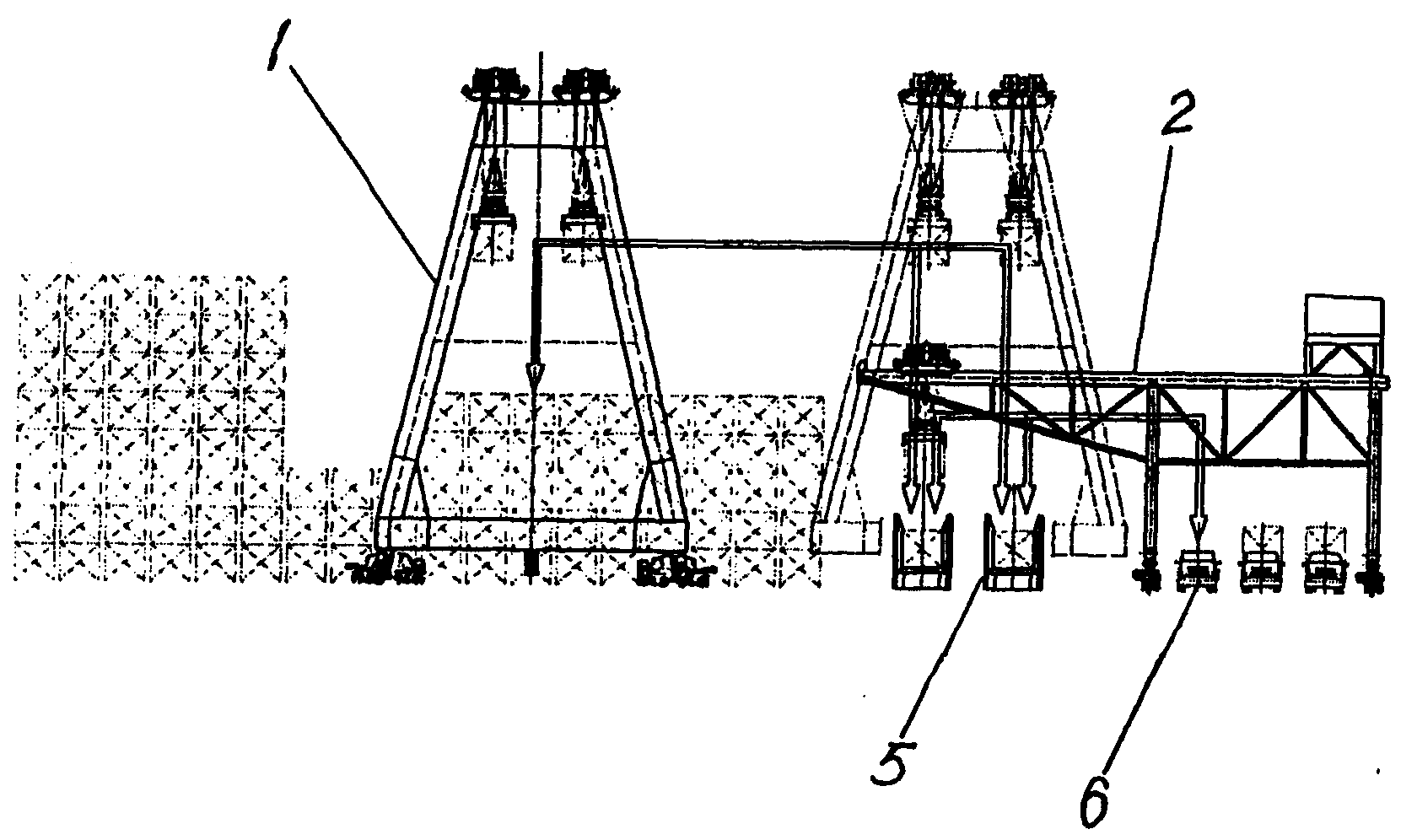

[0011] see figure 1 and figure 2 , the present invention is a relay loading and unloading system of high and low cranes in a container yard. A tall crane 1 and a short crane 2 are arranged on an operation loading and unloading line in the container yard, and the two cranes are respectively provided with independent tracks. The tall crane 1 operates in the box area 3 of the container yard, and the short crane 2 operates in the truck loading and unloading area 4, and the two cranes operate on their respective tracks without interfering with each other. Several container transfer platforms 5 are arranged on the wharf ground between the yard box area 3 and the truck loading and unloading area 4 . figure 1 The middle mark 7 is the running direction of the tall crane cart, the mark 8 is the running direction of the short crane cart, 9 is the running direction of the high crane trolley, and 10 is the running direction of the collection truck.

[0012] The truck loading and unloadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com